A half bearing bush is a part used to protect the shaft, usually made of metal or plastic. It can be installed directly on the shaft to reduce friction and wear between the shaft and the bearing and extend the service life of the shaft and bearing. Bearing pads often come in different shapes and sizes to accommodate different types of shafts and bearings. Bearings are common components in mechanical equipment and are widely used in mechanical transmission, deceleration and rotation.There are also half bearings among oil-free bearings.

1. Bearing structure

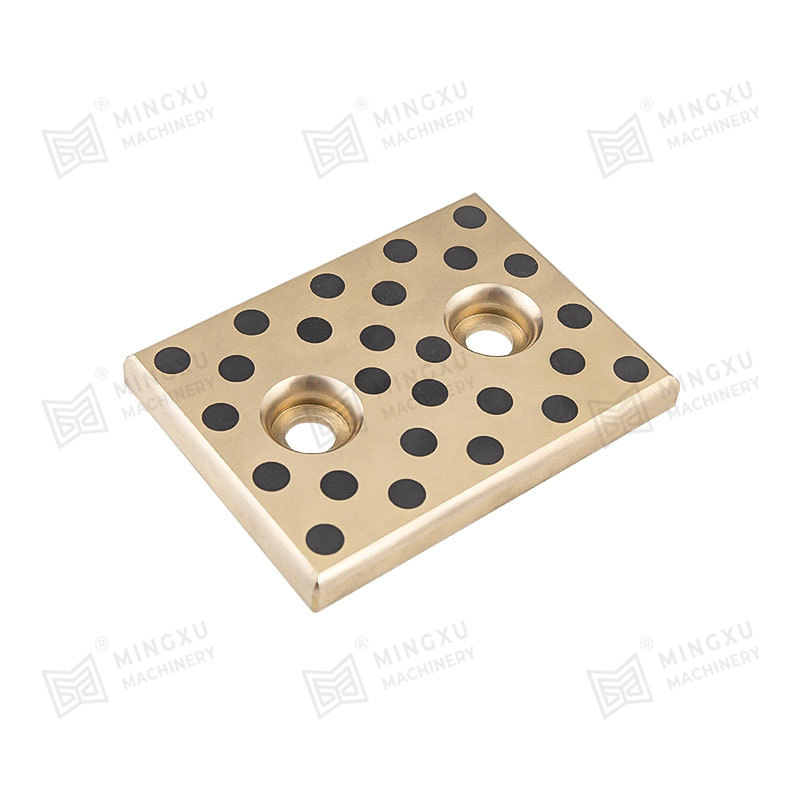

The bearing bush is the part of the bearing that is in direct contact with the journal. The purpose of using the bearing bush on the bearing body is to save valuable bearing materials and facilitate maintenance. There are two types of bearing structures: integral type (also called bushing) and split type. Generally, the shaft sleeve has oil holes and oil grooves for lubrication. The shaft sleeves made of powder metallurgy generally do not have oil grooves.

Split bearings are composed of upper and lower halves. Generally, the lower bearing bears the load and the upper bearing does not bear the load. There are oil holes and oil grooves on the upper bearing pad. After the lubricating oil is input from the oil holes, it is distributed to the entire bearing pad surface through the oil grooves.

Oil grooves and oil holes can only be opened in areas that do not bear loads to avoid reducing the load-bearing capacity of the oil film. The axial length of the oil groove and oil chamber should be shorter than the width of the bearing bush to prevent a large amount of oil from being lost from both ends. The convex shoulders at both ends of the bearing bush can prevent the axial movement of the copper bush and withstand a certain axial force.

2. Bearing material

The main failure modes of bearing bushes are wear and gluing. When the strength is insufficient, fatigue damage may also occur. The main requirements for bearing materials are:

1. Good friction reduction and wear resistance;

2. Sufficient compression resistance, impact resistance and fatigue resistance;

3. Good compliance, embedding, running-in and lubricity;

4. Good thermal conductivity, small linear expansion coefficient, good craftsmanship, etc.

English

English Español

Español

Contact Us