The difference between single-thrust washers and double-thrust washers lies primarily in their design and the direction of the axial forces they can accommodate. Each type serves a specific function in mechanical systems depending on the needs of the application.

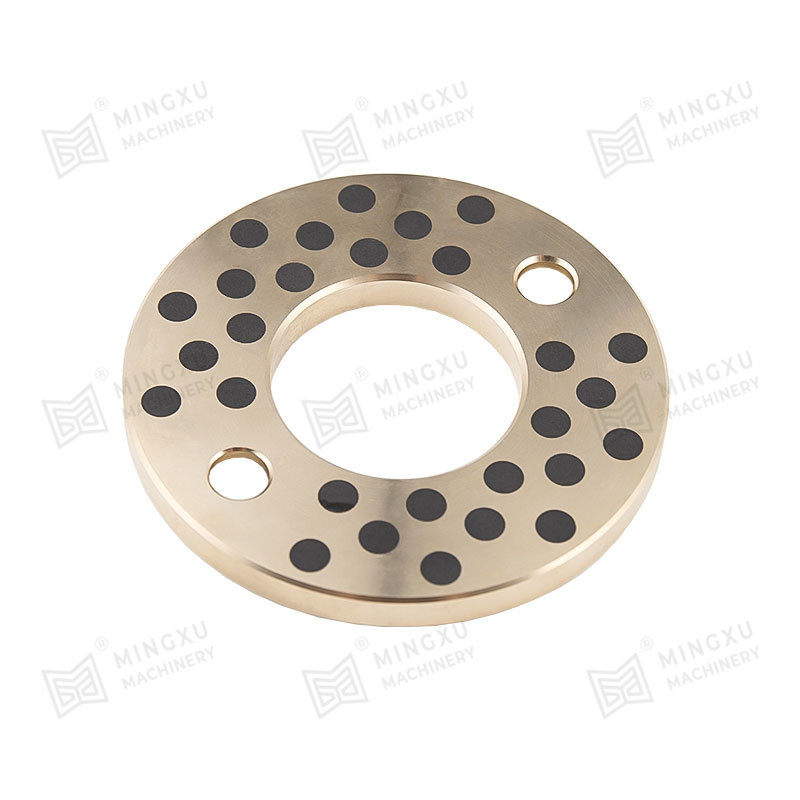

1. Single-Thrust Washer:

Design: A single-thrust washer is a flat washer that typically provides a surface for bearing axial loads in one direction. It has a single bearing surface on one side, which is designed to handle thrust (axial) forces coming from one direction only.

Function: It absorbs and distributes axial loads between a rotating shaft and a stationary component, but only in a single direction (from one side).

Application: Single-thrust washers are used in applications where the axial load is applied in only one direction. Common examples include:

Gearboxes: Where thrust is applied only on one side of the rotating shaft.

Bearings in motors: When the force from rotation is only in one direction.

Automotive transmissions: For cases where thrust from only one side of the shaft needs to be absorbed.

Advantages:

Simpler design.

Less material required, which can reduce costs.

Ideal for applications with unidirectional loads.

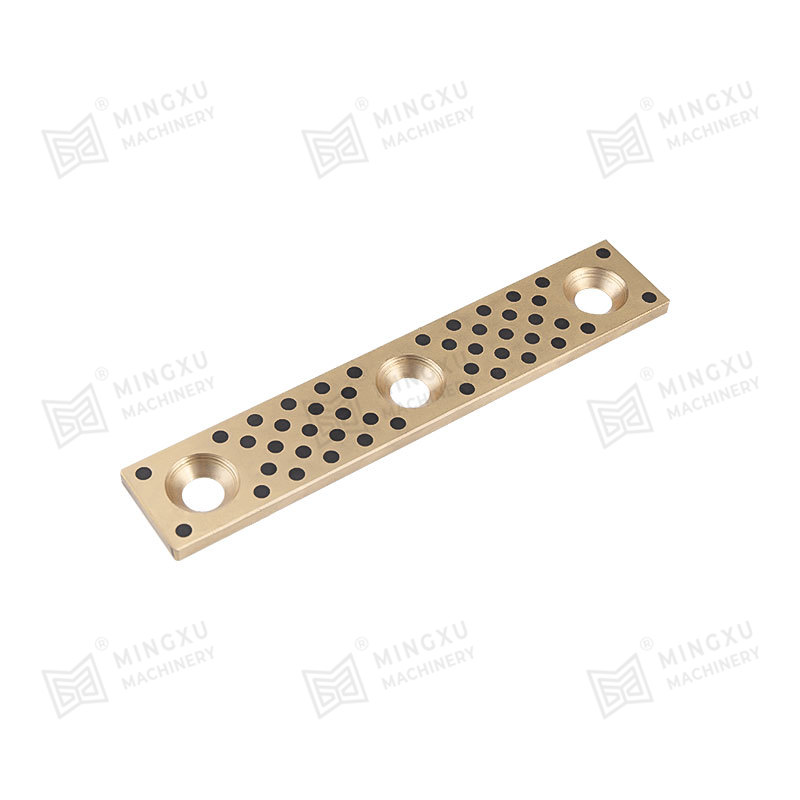

2. Double-Thrust Washer:

Design: A double-thrust washer has two bearing surfaces—one on each side—designed to handle axial loads coming from both directions. It’s essentially a "sandwich" design, with a flat washer-like structure at the center, with thrust surfaces on both sides of the washer.

Function: This washer provides thrust protection from both directions, allowing it to absorb thrust forces acting on both sides of the shaft or rotating part. The double-thrust washer provides more comprehensive load support in machinery with bidirectional thrust.

Application: Double-thrust washers are used in applications where axial forces are applied in both directions. Common examples include:

Rotary machines: Where the direction of thrust changes during rotation, such as in some types of gearboxes, pumps, or compressors.

Automotive differential systems: Where thrust can come from both directions during rotation.

Axle and wheel assemblies: Where forces may be transmitted in both axial directions.

Advantages:

Provides greater thrust capacity in both directions.

More versatile for systems with bidirectional thrust.

Helps balance and stabilize parts that rotate or move back and forth under load.

Key Differences:

Load Direction:

Single-thrust washers handle axial load from one direction only.

Double-thrust washers handle axial load from both directions.

Design Complexity:

Single-thrust washers have a simpler design, with just one thrust-bearing surface.

Double-thrust washers are more complex, having thrust-bearing surfaces on both sides.

Applications:

Single-thrust washers are used in systems where the thrust force is unidirectional.

Double-thrust washers are used in systems with bidirectional thrust forces, where the load direction changes.

When to Use Each:

Single-Thrust Washer: Choose this when the axial load is consistent and applied in only one direction, such as in many industrial machinery, motors, and simple gear drives.

Double-Thrust Washer: This type should be used when axial forces occur in both directions, often in rotating machinery, gear systems that change direction, or applications where thrust reversal is common, like in some pumps or compressors.

English

English Español

Español

Contact Us