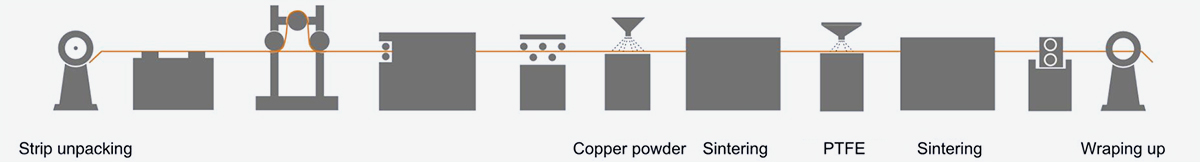

SF stands for three-layer composite, namely steel plate layer, copper powder layer and plastic layer. The steel plate layer plays the role of assembly positioning and bearing pressure; the copper powder layer plays the role of connecting plastic and auxiliary friction reduction; the plastic layer plays the role of wear resistance and self-lubrication. Its advantages are that it can also self-lubricate without oil, low noise during operation, thin-walled design structure with small volume, and wear resistance can be maintained for a long time without wear. It is a new type of bearing that replaces needle roller bearings, oil-containing bearings, and copper alloy bearings.

The advantages of SF series bearings are the use of high-end equipment in the production process, strong automated production capacity, small product wall thickness tolerance, high precision, advanced product formula technology, and can conduct working condition simulation tests according to customer personalized needs. Product quality and research and development technology are at the international advanced and domestic leading level.

Features

A three-layer composite product with a steel base, a bronze sintered layer, and a PTFE resin layer containing fillers.

Simple type with thin wall thickness.

Shows a stable low friction coefficient under heavy load and low speed conditions, and excellent wear resistance.

When used with lubricant, it can be used with a high PV value even in the medium and high speed range.

Excellent chemical resistance.

English

English Español

Español