MXB-FB090 Bronze Coiled Bearing With good Wear Resistance

Cat:Oilless Bearing

FB090 bronze bearings are made of tin bronze alloy CuSn8. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according ...

See Details

When comparing the performance and application scenarios of H62 brass and high-strength brass (chemical formula: ZCuZn25Al6Fe3Mn3), it’s essential to conduct a thorough analysis from multiple perspectives, including chemical composition, mechanical properties, corrosion resistance, workability, and cost. High-strength brass clearly outperforms H62 brass in terms of strength, hardness, corrosion resistance, and adaptability to complex environments. It can replace H62 brass in most industrial scenarios. However, the decision should be made based on specific needs, weighing the cost against processing difficulties.

Content

Composition: Approximately 65% copper, about 24% zinc, with added elements such as aluminum (6%), iron (3%), and manganese (3%).

Microstructure: Forms an α+β duplex structure. The β phase is an ordered solid solution that significantly enhances strength.

Effects of Alloying:

Conclusion: The alloying design of high-strength brass gives it inherent advantages in terms of strength, hardness, and corrosion resistance.

High-Strength Brass:

H62 Brass:

High-Strength Brass:

H62 Brass:

Case Study:

Data: The corrosion rate of high-strength brass in a 3.5% NaCl solution is only one-third that of H62 brass.

Trade-off:

With its comprehensive performance advantages, high-strength brass has become an ideal alternative to H62 brass in high-end industrial applications. However, the decision should be based on specific scenarios, weighing cost against performance requirements.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. specializes in the research, development, and production of copper alloy components and self-lubricating bearings, providing high-strength brass raw materials and machined components.

FB090 bronze bearings are made of tin bronze alloy CuSn8. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according ...

See Details

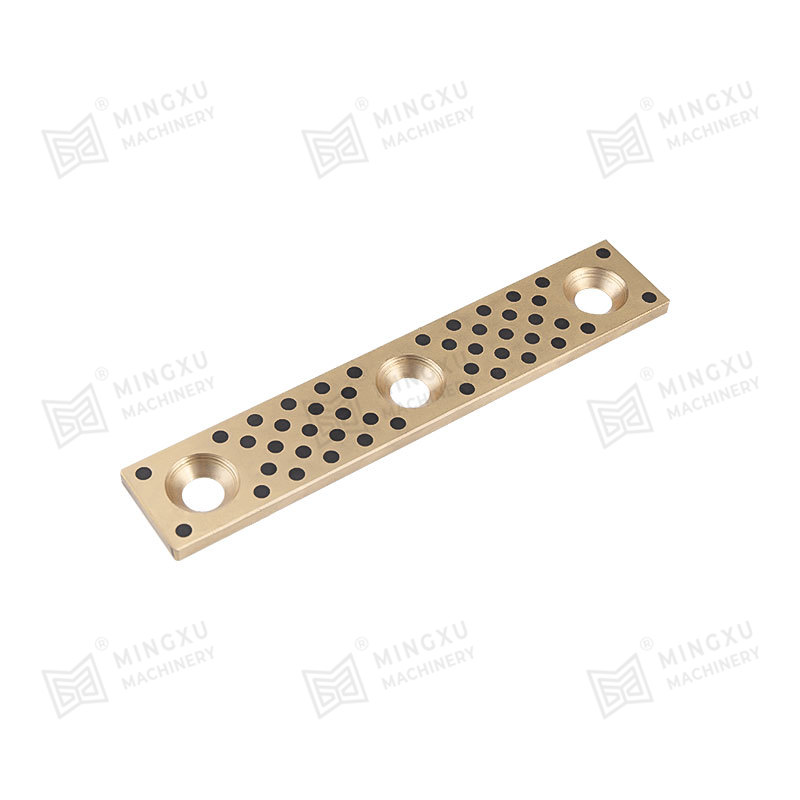

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JOML self-lubricating wear plates are designed to minimize friction and extend service life in industrial applications. The product is made from a...

See Details

MXB-JTGLW self-lubricating guide rails provide resistance and reduce friction, ensuring extended durability and enhanced performance. This product pro...

See Details

MXB-JGLXS guide rails are parts installed on both sides of the side core-pulling slider to ensure that the side core-pulling slider moves back and for...

See Details

MSEW JIS 20mm Standard Wear Plate is based on high-strength brass, tin bronze, steel-copper bimetal, cast iron or bearing steel. The surface is inlaid...

See Details

Normally, the push plate is supported by four reset rods. However, due to the low installation accuracy of the reset rods, when the push plate is larg...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1D hydraulic bearing is a new type of material designed based on SF-1P and combining the working principle of oil cylinder and shock absorber. It i...

See Details

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

See Details

Contact Us