Oilless bearings, also known as self-lubricating or dry bearings, are designed to operate without external lubrication such as oil or grease. They are engineered to reduce friction and wear while simplifying maintenance, making them suitable for a wide range of industrial, automotive, and mechanical applications. Oilless bearings often incorporate solid lubricants or porous structures that release lubrication over time, ensuring consistent performance even in harsh or inaccessible environments.

Choosing the right oilless bearing requires understanding its construction, material properties, load capacity, environmental conditions, and intended application. Proper selection ensures durability, reduces downtime, and improves the overall efficiency of machinery.

Materials and Construction

Oilless bearings are made from a variety of materials, each offering specific advantages. Common materials include bronze, sintered metal, composite polymers, and PTFE-based laminates. The choice of material affects wear resistance, load capacity, chemical compatibility, and temperature tolerance.

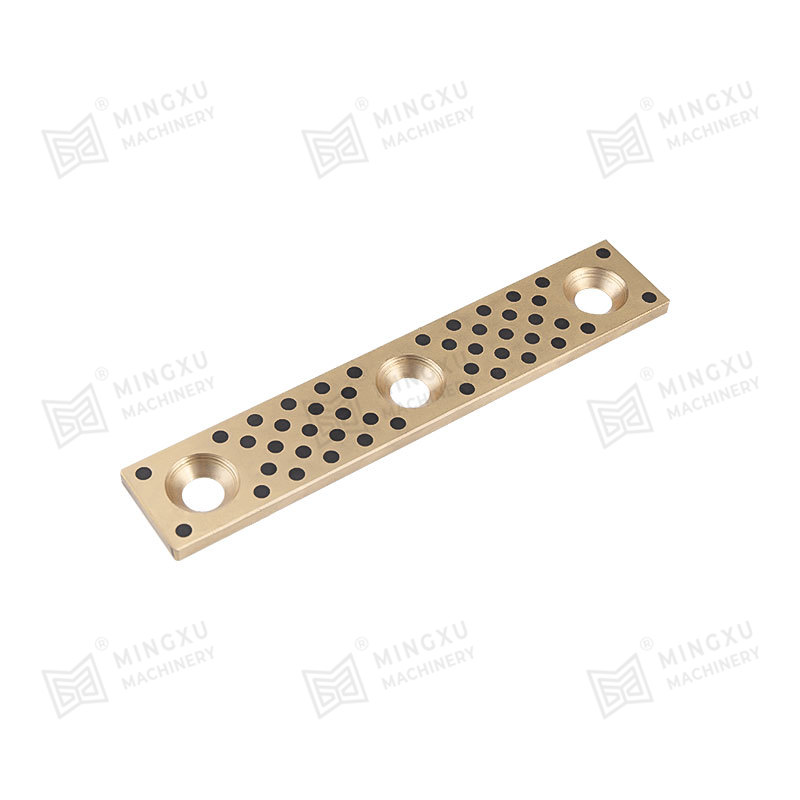

Bronze Bearings

Bronze oilless bearings are durable and suitable for moderate to high load applications. They often contain embedded lubricants such as graphite or copper alloys, providing low friction under continuous operation. Bronze bearings are ideal for automotive components, industrial machinery, and rotating shafts.

Polymer and Composite Bearings

Polymer and composite oilless bearings offer lightweight solutions with excellent chemical resistance and corrosion protection. They are suitable for environments where exposure to moisture, chemicals, or contaminants is common. These bearings are frequently used in food processing equipment, medical devices, and packaging machinery.

Sintered Metal Bearings

Sintered metal bearings are produced by compressing and heating powdered metal, creating a porous structure that can retain lubricants within its pores. This design allows gradual lubrication release, extending service life. Sintered bearings are particularly effective in high-speed or high-load machinery.

Load Capacity and Operating Conditions

When selecting an oilless bearing, consider the type of load it will bear. Bearings are designed for radial loads, axial loads, or combined load conditions. The maximum allowable load depends on the material, design, and intended application. Overloading can lead to premature wear or failure.

Operating conditions such as temperature, speed, and environmental exposure are also critical. High-temperature environments require heat-resistant materials, while high-speed applications need low-friction surfaces. For corrosive or wet conditions, polymer or composite bearings often provide better longevity than metal-based options.

Comparing Common Oilless Bearings

| Bearing Type |

Material |

Load Capacity |

Ideal Application |

| Solid Bronze |

Bronze with graphite |

High |

Industrial machinery, shafts, automotive |

| Sintered Metal |

Porous bronze or iron |

Medium to High |

High-speed, high-load components |

| Polymer Composite |

PTFE or reinforced polymer |

Medium |

Food processing, medical, chemical environments |

Maintenance and Longevity

One of the main advantages of oilless bearings is their low-maintenance design. Unlike traditional lubricated bearings, they do not require regular oiling or greasing. However, proper installation, load management, and regular inspection of alignment and wear are still important to ensure long-term performance.

Selecting high-quality materials and suitable bearing types for the operating environment reduces the risk of failure, extends service life, and improves machine efficiency. Oilless bearings are particularly beneficial in applications where lubrication access is limited or contamination is a concern.

Conclusion: Choosing the Right Oilless Bearing

Selecting the correct oilless bearing involves evaluating material, load capacity, operating conditions, and intended application. Understanding the differences between solid bronze, sintered metal, and polymer composite bearings helps match the right bearing to your machinery. Proper selection ensures durability, reduces maintenance requirements, and enhances the performance and reliability of your equipment.

English

English Español

Español

Contact Us