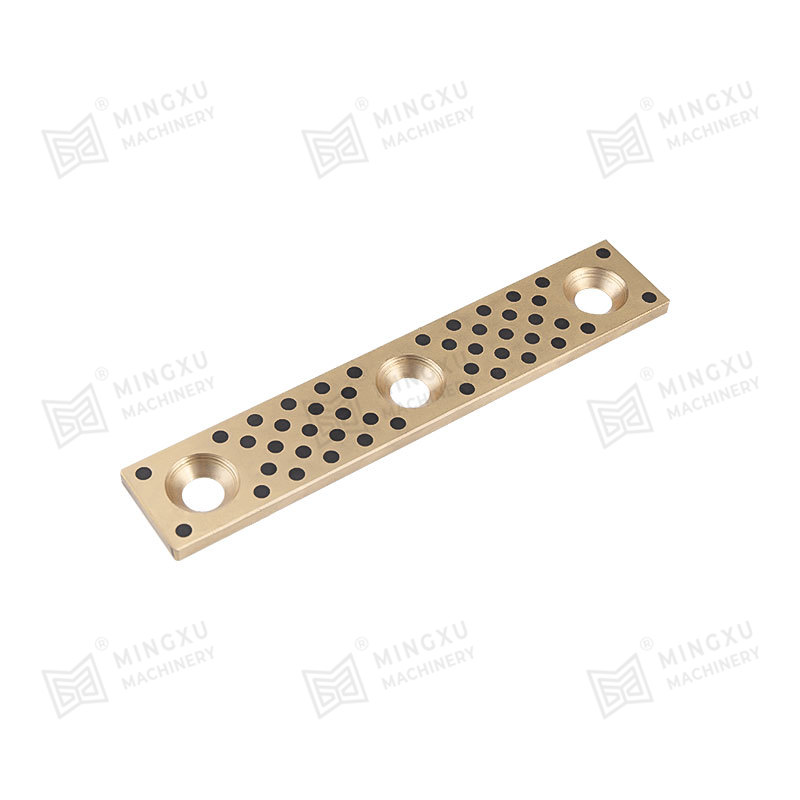

MXB-DX Boundary Oilless Bearing SF-2 Dry Plain Bearing

Cat:Oilless Bearing

MXB-DX boundary oil-free bearings, equivalent to SF-2 self-lubricating or dry plain bearings, which is based on steel plate, sintered spherical bronze...

See DetailsGuide rails play a critical role in linear motion systems, ensuring smooth, accurate, and reliable operation. Traditionally, guide rails required frequent lubrication with oils or greases to reduce friction and wear. While effective, these lubrication systems introduced challenges such as high maintenance costs, contamination risks, and inconsistent performance in demanding environments.

To overcome these issues, manufacturers have increasingly turned to self-lubricating guide rails. These components integrate lubrication materials—such as solid lubricants, polymer composites, or embedded lubrication reservoirs—directly into the rail design. This eliminates or reduces the need for external lubrication, extending service life and improving reliability.

Today, self-lubricating guide rails are being widely adopted across multiple industries where maintenance-free operation, cleanliness, and efficiency are essential. Below is a closer look at the key sectors driving this transition.

Content

The automotive sector has been one of the earliest adopters of self-lubricating guide rails. In assembly lines and robotic systems, where precision and uptime are critical, self-lubricating rails reduce downtime caused by lubrication schedules.

Applications:

The reduced maintenance requirements directly translate into lower operating costs and higher production efficiency.

In food processing, packaging, and bottling plants, avoiding contamination is a top priority. Traditional greases and oils pose contamination risks, while constant cleaning and relubrication create inefficiencies.

Self-lubricating guide rails solve this problem by providing lubrication-free operation that complies with hygiene and safety standards. Many rails are designed with FDA-compliant materials, making them safe for direct or indirect food contact.

Applications:

By eliminating external lubricants, these rails support clean, low-maintenance, and hygienic operations.

Similar to the food sector, the medical and pharmaceutical industries require ultra-clean environments. Equipment used in laboratories, diagnostic machines, and pharmaceutical packaging lines must operate smoothly without introducing contaminants.

Self-lubricating guide rails are ideal because they provide consistent performance without external lubrication, which could compromise sterile conditions. They also offer quiet operation, which is valued in hospital and lab settings.

Applications:

This industry values the maintenance-free and clean-running properties of self-lubricating guide rails.

The packaging sector demands high-speed and high-precision machinery that operates continuously. Frequent lubrication interruptions reduce output and increase costs.

By integrating self-lubricating rails, packaging equipment manufacturers achieve faster throughput, reduced downtime, and longer service life for critical motion components.

Applications:

The combination of efficiency and low maintenance makes self-lubricating guide rails increasingly popular in packaging plants worldwide.

The electronics sector requires extremely clean environments for component assembly and semiconductor fabrication. Any oil or grease particles can damage sensitive products or interfere with micro-level precision.

Self-lubricating guide rails are widely used in cleanrooms and precision equipment, where they enable particle-free operation. Their smooth, low-friction performance enhances positioning accuracy in high-tech machinery.

Applications:

This industry adopts self-lubricating solutions to ensure reliability, precision, and contamination-free operation.

Textile machinery often operates at high speeds and over long production cycles, creating significant wear on moving parts. Regular lubrication can be time-consuming and difficult in dusty environments, where lubricants attract fibers and debris.

Self-lubricating guide rails minimize these challenges, providing clean, long-lasting operation without frequent intervention.

Applications:

The result is improved machine efficiency and reduced downtime in textile manufacturing.

In industrial automation and heavy machinery, reliability is key. Equipment often operates in harsh environments where external lubrication may fail or attract dirt and dust.

Self-lubricating guide rails are particularly valuable in these conditions, as they reduce wear and maintain performance even under heavy loads.

Applications:

By replacing traditional lubrication systems, these rails lower overall maintenance demands and extend service life.

The broad adoption of self-lubricating guide rails is driven by several universal benefits:

Industries ranging from automotive, food and beverage, medical, packaging, electronics, textiles, to industrial automation are increasingly adopting self-lubricating guide rails as replacements for conventional lubrication systems. The move is motivated by the need for cleaner, more efficient, and lower-maintenance solutions that align with modern manufacturing standards.

As technology advances, self-lubricating materials will continue to evolve, expanding their role in even more industries where reliability and performance are critical. The growing adoption across diverse sectors demonstrates the pivotal role self-lubricating guide rails play in shaping the future of motion systems.

MXB-DX boundary oil-free bearings, equivalent to SF-2 self-lubricating or dry plain bearings, which is based on steel plate, sintered spherical bronze...

See Details

FB090 bronze bearings are made of tin bronze alloy CuSn8. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according ...

See Details

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JOML self-lubricating wear plates are designed to minimize friction and extend service life in industrial applications. The product is made from a...

See Details

MXB-JGLDW self-lubricating guide rails are made of high-strength brass through CNC machine tools. The surface is inlaid with solid lubricants such as ...

See Details

MJGB oil-free injection guide bushings are standard components used in the plastic injection molding process, providing lubrication-free guidance and ...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1S stainless steel corrosion-resistant bearing is a very effective corrosion-resistant material that is formed by rolling with stainless steel as t...

See Details

SF-PK PEEK triple composite bearing is a novel sliding bearing, which consists of steel plate, copper powder layer, PTFE + filling material. The main ...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us