Oilless bushings are a type of bearing that operates without the need for lubrication, making them an essential component in various mechanical systems. These self-lubricating bearings are designed to provide smooth operation and reduce friction, wear, and the need for frequent maintenance. In this article, we’ll explore what oilless bushings are, how they work, their advantages, and where they are commonly used.

Oilless bushings, also known as self-lubricating bushings or plain bearings, are mechanical components that support rotating or sliding shafts while reducing friction and wear. Unlike traditional bushings that require external lubrication, oilless bushings are made from special materials that contain lubricants embedded within their structure. These materials allow the bushing to operate smoothly without the need for additional oils, grease, or other lubricants.

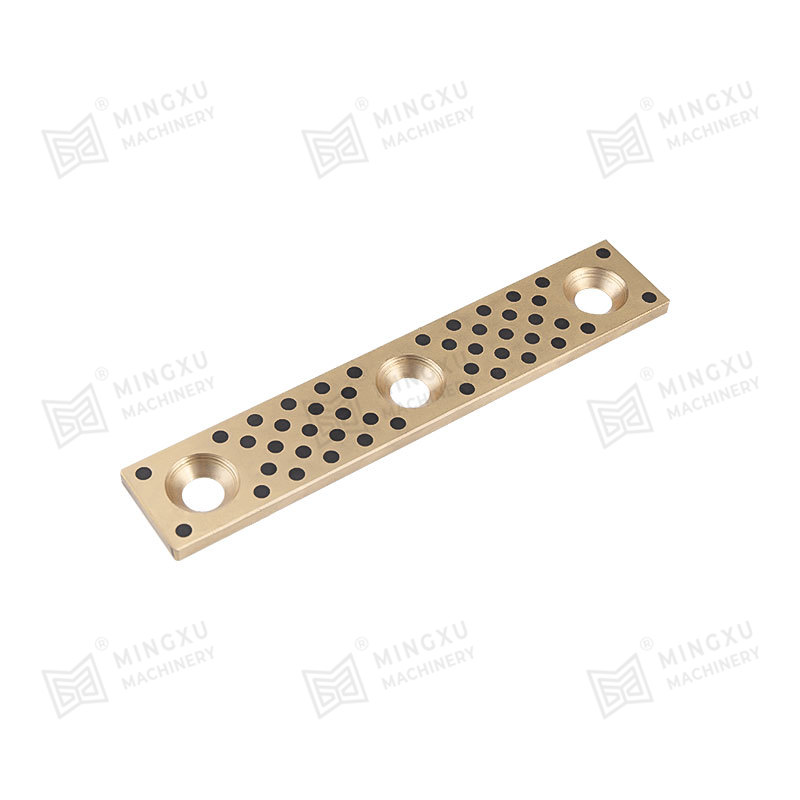

Oilless bushings are typically made from a combination of metal alloys, such as bronze or copper, and lubricating compounds like graphite, PTFE (polytetrafluoroethylene), or other solid lubricants. The presence of these lubricants within the bushing material ensures that the bearing surface remains lubricated throughout its operation.

2. How Do Oilless Bushings Work?

Oilless bushings work on the principle of self-lubrication. The lubricants embedded in the bushing material are gradually released over time as the bearing moves, creating a thin film of lubricant between the shaft and the bushing surface. This lubrication reduces friction, which in turn minimizes heat generation and wear, ensuring smooth and reliable operation.

The lubricating material is typically mixed into the matrix of the bushing material or applied as a surface layer. As the shaft rotates or moves within the bushing, the lubricant is transferred to the contact surfaces, forming a protective film that prevents direct metal-to-metal contact. This reduces the risk of damage caused by friction and extends the lifespan of the bushing.

3. Key Components of Oilless Bushings

The primary components that make oilless bushings effective include:

a. Base Material

The base material is typically a metal, such as bronze, which provides strength and durability. This metal acts as the framework for the bushing and ensures it can withstand the mechanical forces placed on it during operation.

b. Lubricant

The lubricant is embedded within the base material or applied to the surface of the bushing. Common lubricants include graphite, PTFE, and other solid lubricants that provide low friction and wear resistance. These lubricants are essential for maintaining smooth movement and reducing the need for external lubrication.

c. Porous Structure

Some oilless bushings feature a porous structure that allows for better distribution of the lubricating material. This structure ensures that the lubricant is evenly spread across the contact surfaces, promoting consistent performance and reducing the chance of localized wear.

4. Advantages of Oilless Bushings

Oilless bushings offer several advantages over traditional lubricated bushings. Some of the key benefits include:

a. Reduced Maintenance

Since oilless bushings do not require external lubrication, they are virtually maintenance-free. This can save time and costs associated with routine lubrication, making them ideal for applications where regular maintenance is challenging or costly.

b. Cleaner Operation

Without the need for oil or grease, oilless bushings operate in a cleaner manner, reducing the risk of contamination in sensitive environments. This is especially important in industries such as food processing, pharmaceuticals, and electronics, where cleanliness is critical.

c. Longer Service Life

The self-lubricating nature of oilless bushings helps reduce friction and wear, which can extend the life of both the bushing and the shaft. This results in lower maintenance costs and fewer replacements over time.

d. Energy Efficiency

By reducing friction, oilless bushings help improve the overall energy efficiency of machinery. The smooth operation of these bearings reduces the amount of energy required to move the parts, contributing to overall energy savings in various systems.

e. Environmentally Friendly

Oilless bushings are more environmentally friendly compared to traditional lubricated bearings because they eliminate the need for oil and grease. This reduces the risk of spills and contamination and lowers the environmental impact associated with lubrication.

5. Applications of Oilless Bushings

Oilless bushings are used in a wide range of industries and applications where traditional lubrication is not practical or desirable. Some of the most common applications include:

a. Automotive Industry

In the automotive industry, oilless bushings are used in parts like suspension systems, steering components, and engines. These bushings help reduce the friction between moving parts, improving the performance and longevity of vehicles.

b. Industrial Machinery

Oilless bushings are commonly used in various industrial machines, such as conveyor systems, pumps, and motors. They are particularly useful in environments where regular lubrication is difficult, such as in high-speed machinery or environments with high dust and dirt levels.

c. Food and Beverage Processing

In food and beverage processing, hygiene is a top priority. Oilless bushings are used in equipment like mixers, conveyors, and filling machines, as they reduce the risk of contamination from oils and grease, ensuring that the production process remains sanitary.

d. Agricultural Machinery

Oilless bushings are also used in agricultural machinery like tractors, harvesters, and irrigation systems. These bushings can withstand harsh environments and reduce the need for frequent lubrication, which is especially important in remote or outdoor settings.

e. Marine Applications

In marine environments, oilless bushings are used in equipment like rudder systems, winches, and other moving parts on ships. The ability to operate without external lubrication is crucial in such environments, where oil and grease can break down due to water exposure.

6. Types of Oilless Bushings

Oilless bushings come in various designs to suit different applications. Some common types include:

a. Flanged Bushings

These bushings have a flange at one end, which helps to secure the bushing in place and prevent it from sliding out of its housing. Flanged bushings are often used in automotive and industrial applications.

b. Sleeve Bushings

Sleeve bushings are cylindrical in shape and are commonly used for applications that require simple, straightforward support for a shaft or spindle.

c. Sintered Bronze Bushings

These bushings are made from sintered bronze material, which is porous and allows for better lubricant distribution. Sintered bronze bushings are often used in applications with moderate loads and speeds.

7. Conclusion

Oilless bushings provide a reliable, low-maintenance solution for reducing friction and wear in mechanical systems. Their ability to operate without external lubrication makes them ideal for a variety of industries and applications, from automotive to food processing. By choosing the right type of oilless bushing for your needs, you can improve the efficiency and lifespan of your machinery while reducing maintenance costs and environmental impact.

English

English Español

Español

Contact Us