Zhejiang Mingxu Machinery Manufacturing Co., Ltd. is a professional manufacturer of engineering machinery accessories self-lubricating bearings. The company adopts advanced production technology and specializes in the production of various types of engineering machinery accessories copper sleeves, self-lubricating bearings, etc. If you want to know more information such as product prices and models, please feel free to contact us at [email protected].

Engineering machinery is an important part of the equipment industry and a national heavy equipment in large infrastructure. Its variety, quantity and quality can be said to directly affect the development of a country's production and construction. It is mainly used in national defense construction projects, transportation construction, energy industry construction and production, mining and other raw materials industry construction and production, agriculture, forestry and water conservancy construction, industrial and civil construction, urban construction, environmental protection and other fields. Due to the particularity of the environment, the general application field environment of engineering machinery is relatively harsh. Therefore, in actual work, there will be many factors that lead to bearing failure, such as abnormal wear of the shaft hole, loss of lubrication function, and bearing failure caused by poor working environment of the equipment, large impact load, uneven working surface, insufficient injected lubricating oil, etc. In order to ensure reliable operation under high-intensity working conditions, bearings play a very important role in engineering machinery.

Application of self-lubricating bearings in engineering machinery

In engineering machinery, self-lubricating bearings are widely used in various components such as chassis travel mechanisms, body parts, hydraulic components, etc. Self-lubricating bearings have excellent wear resistance and dust resistance under high load conditions. At the same time, self-lubricating technology greatly extends the maintenance cycle of bearings, improves the utilization rate of equipment, and reduces maintenance costs.

The application of self-lubricating bearings (also called oil-free lubricating bearings) in the control system of engineering machinery instead of needle bearings can effectively solve the problem of high failure rate, greatly improve the control stability and component reliability, and solve this stubborn problem that has long plagued the control system of engineering machinery.

The crawler travel mechanism of the engineering machinery excavator consists of a driving wheel, a guide wheel and a supporting wheel. Their shafts are connected to the frame through sliding bearings to form an effective mechanical mechanism. Each sliding bearing adopts dual-pipeline forced automatic centralized lubrication, but self-lubricating bearings are generally used.

Advantages of self-lubricating bearings: reliable, lightweight, excellent bearing solutions

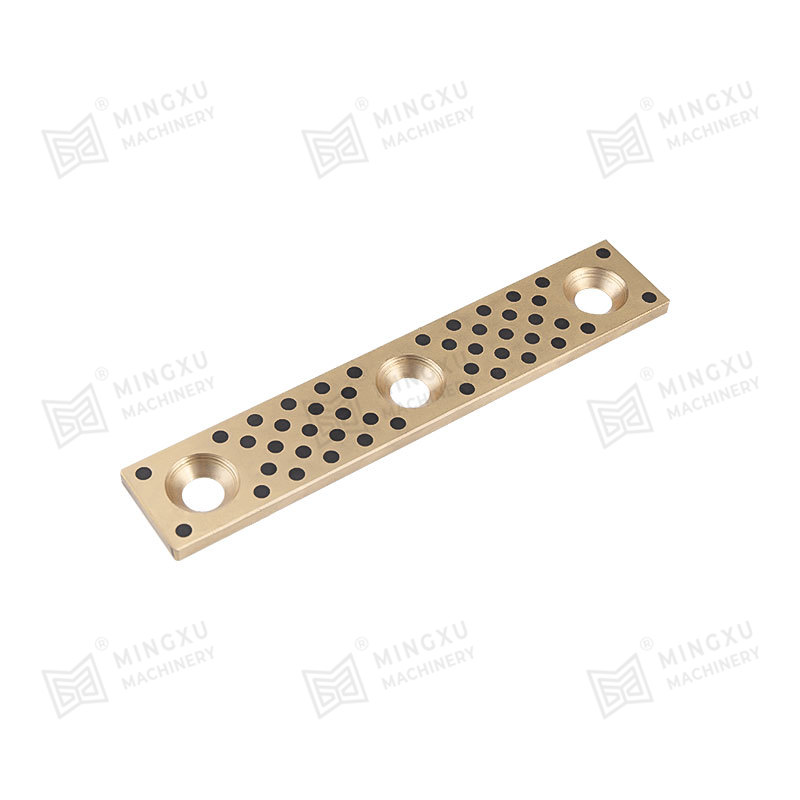

Solid-inlaid self-lubricating bearings are made by opening holes of appropriate size and orderly arrangement on the metal friction surface of the bearing matrix, and then embedding molded solid lubricants with unique lubrication properties in the holes (the area of the solid lubricant is generally 25%-35% of the friction area) to make self-lubricating bearings. This bearing combines the advantages of the metal matrix and the specially formulated lubricating material, breaking through the limitation of general bearings relying on oil film lubrication.

Impact-resistant, dust-resistant, high-strength self-lubricating bearings can provide more reliable performance than traditional bearings, not only can they solve lubrication problems, but also can effectively reduce noise and extend service life, especially in harsh mines and field equipment, such as excavator arm bearings, chassis walking mechanisms, hydraulic cylinder oil pumps, etc.

English

English Español

Español

Contact Us