In the retrofitting of die-casting machines, the application of self-lubricating bearings offers numerous advantages. The following outlines the specific application scenarios:

1. Working Characteristics of Die-Casting Machines and Issues with Existing Bearings

Working Characteristics of Die-Casting Machines

High-Temperature Environment: During the die-casting process, molten metal is injected into the mold cavity, generating a significant amount of heat and raising the temperature around some key components of the die-casting machine. For instance, temperatures near the injection system can often reach several hundred degrees Celsius.

High-Load Operation: Die-casting machines need to apply substantial pressure to ensure that the molten metal fills the mold cavity completely, subjecting their components to enormous radial and axial loads. For example, the clamping mechanism must bear the weight of the mold and the clamping force during the closing and opening processes.

Frequent Motion: Many components of die-casting machines, such as the injection rod and moving platen, undergo frequent reciprocating motion, leading to rapid wear of traditional bearings.

Issues with Existing Bearings

Lubrication Difficulties: In high-temperature environments, traditional lubricating greases tend to dry out and dissipate, resulting in lubrication failure. Moreover, the complex internal structure of die-casting machines makes it challenging to perform regular manual lubrication on some bearings.

Severe Wear: Due to high loads and frequent motion, traditional bearings wear out quickly, affecting the precision of the die-casting machine and increasing maintenance costs and downtime.

2. Advantages of Self-Lubricating Bearings

Self-Lubricating Performance

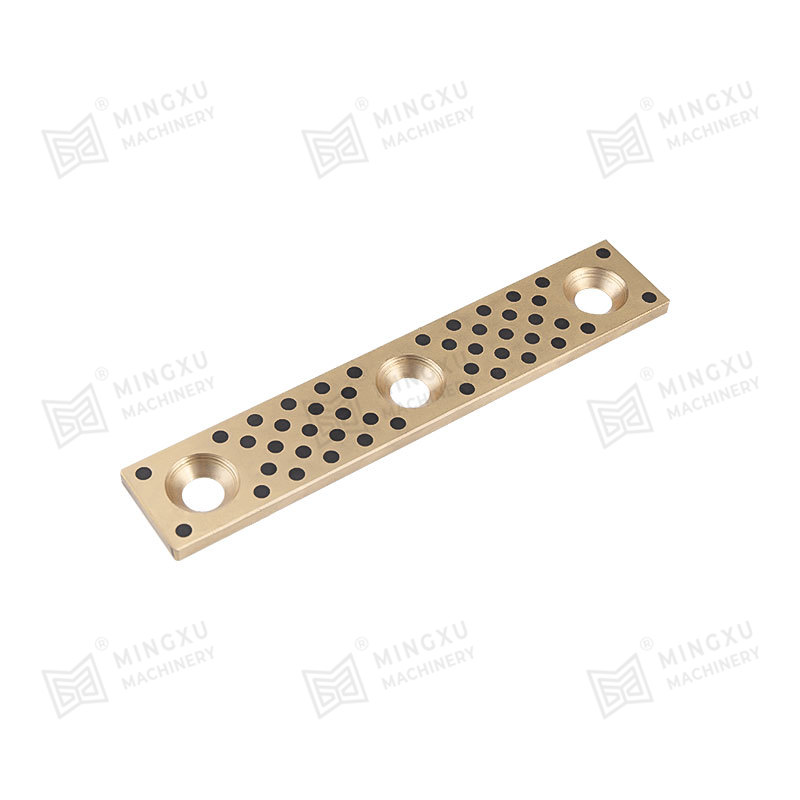

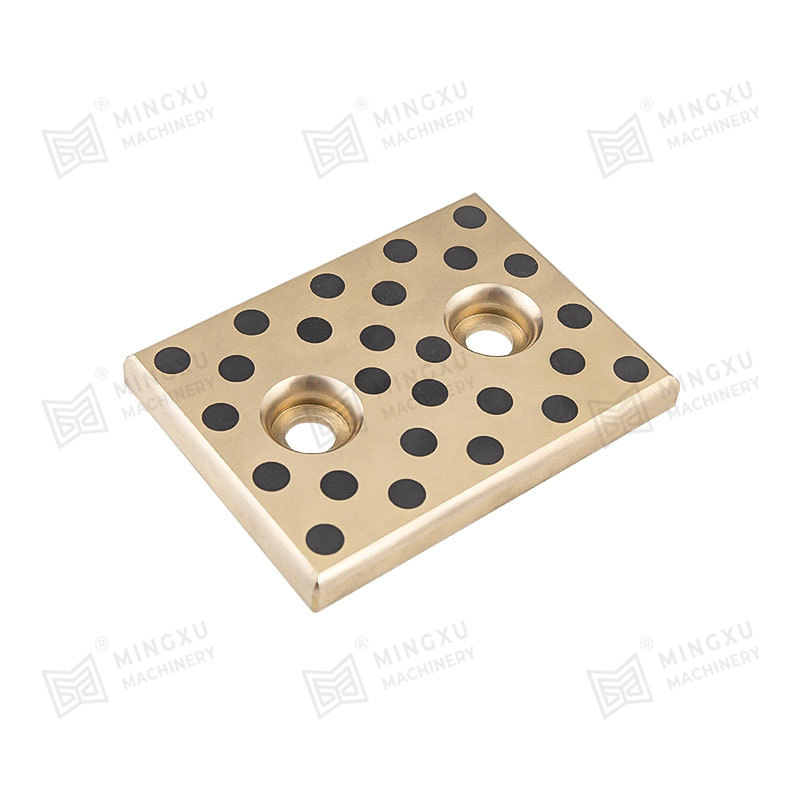

Reduced Maintenance Workload: Self-lubricating bearings are embedded with solid lubricants such as graphite and polytetrafluoroethylene (PTFE). These solid lubricants are automatically released onto the friction surface during bearing operation, forming a lubricating film and eliminating the need for external grease addition, significantly reducing the maintenance workload.

Adaptability to Complex Working Conditions: Self-lubricating bearings maintain good lubricating performance even in high-temperature environments encountered in die-casting machines. For example, self-lubricating bearings containing graphite remain stable at high temperatures, providing continuous lubrication for the bearings.

Wear Resistance

Extended Service Life: The combination of solid lubricants and bearing matrix materials in self-lubricating bearings effectively reduces the friction coefficient and wear. Compared to traditional bearings, their wear rate can be reduced by 30% to 60%, significantly extending the service life of the bearings and reducing the frequency of equipment replacement.

Maintained Equipment Precision: With reduced wear, key components of the die-casting machine can maintain high precision over extended periods, ensuring stable quality of die-cast products.

High Load-Bearing Capacity

Adaptability to High Loads in Die-Casting Machines: The matrix materials of self-lubricating bearings typically possess high strength, enabling them to withstand the enormous radial and axial loads generated during die-casting machine operation. For example, some self-lubricating bearings with a copper alloy matrix can achieve high compressive strength values, meeting the load-bearing requirements of components such as the clamping mechanism in die-casting machines.

3. Specific Application Areas

Injection System

Injection Rod Bearings: The injection rod undergoes frequent reciprocating motion and is subjected to high pressure during the die-casting process. The use of self-lubricating bearings ensures smooth motion of the injection rod, reduces friction and wear, and improves injection accuracy and efficiency.

Injection Cylinder Bearings: Bearings inside the injection cylinder, when using self-lubricating bearings, can operate stably under high-temperature and high-pressure conditions, ensuring the normal operation of the injection cylinder and avoiding injection instability caused by bearing failures.

Clamping System

Guide Bearings for Moving and Fixed Platens: During the closing and opening processes, the guide bearings between the moving and fixed platens must bear the weight of the mold and the clamping force while ensuring accurate platen motion. Self-lubricating bearings provide good guidance and support while reducing wear, ensuring clamping precision.

Adjusting Mechanism Bearings: The adjusting mechanism is used to adjust the thickness of the mold. The application of self-lubricating bearings in its bearings facilitates adjustment operations and enables the mechanism to withstand certain axial loads during the die-casting process, ensuring the stability of the adjusting mechanism.

4. Precautions During the Retrofitting Process

Bearing Selection

Matching Based on Working Conditions: It is necessary to select the appropriate type of self-lubricating bearing based on factors such as the working temperature, load magnitude, and motion speed at different locations of the die-casting machine. For example, for bearings in high-temperature areas, graphite-inlaid self-lubricating bearings with better high-temperature resistance can be chosen; for locations with high loads, bearing models with high load-bearing capacity should be selected.

Matching Dimensional Precision: Ensure that the dimensions of the self-lubricating bearings precisely match those of the original bearing positions in the die-casting machine, including inner diameter, outer diameter, and length, to avoid loose or tight installations.

Installation Requirements

Clean Installation Environment: During the installation of self-lubricating bearings, ensure that the bearing installation positions in the die-casting machine are clean to prevent impurities from entering the bearings and affecting their performance.

Correct Installation Method: Follow the installation instructions for self-lubricating bearings to avoid damaging the bearings with excessive installation forces. For interference-fit bearings, appropriate heating or cooling methods can be used for installation to ensure that the bearings are properly seated without damage.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the research, development, and production of copper alloy components and self-lubricating bearings for over a decade, with extensive production experience and technological accumulation. For any product or technical inquiries, please feel free to contact us at [email protected].

English

English Español

Español

Contact Us