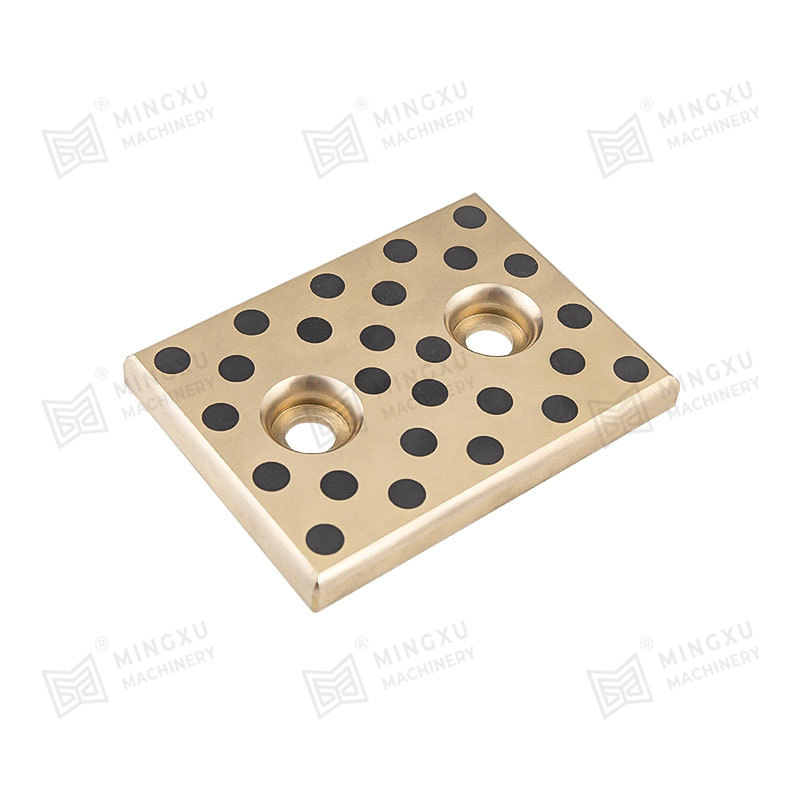

I. Guiding Function of Copper-Based Inlaid Self-Lubricating Sliding Plates in Automotive Stamping Dies

In automotive stamping dies, high-precision guiding is essential during the stamping process to ensure accurate closing and opening of the upper and lower die halves. Copper-based inlaid self-lubricating sliding plates, with their low coefficient of friction, provide excellent guiding for the moving components of the die, reducing the impact of lateral forces on the die and ensuring the forming accuracy of stamped parts. For example, in stamping dies for large automotive body panels, which have complex shapes and large dimensions, extremely high guiding precision is required. The use of copper-based inlaid self-lubricating sliding plates can effectively enhance the guiding performance of the die, thereby improving the quality of stamped parts. This is because the solid lubricant embedded in the plates continuously provides lubrication during operation, maintaining good guiding properties even after prolonged use.

II. Adaptability to the Working Environment of Automotive Stamping Dies

Adaptability to Heavy-Load Conditions

Automotive stamping dies often need to withstand significant stamping forces during operation. The high load-bearing capacity of copper-based inlaid self-lubricating sliding plates enables them to adapt to such heavy-load conditions. With a copper matrix providing high strength and the embedded solid lubricant effectively reducing friction, these plates can minimize wear on die components while withstanding large pressures, thereby extending the service life of the die. For instance, in stamping dies for large structural components such as automotive frames, where stamping forces may reach several tens or even hundreds of tons, copper-based inlaid self-lubricating sliding plates can operate stably, ensuring the normal functioning of the die.

Coping with Low-Speed Reciprocating Motion

The motion of automotive stamping dies is predominantly low-speed reciprocating. Under such motion conditions, conventional lubrication methods may struggle to provide continuous and effective lubrication. Copper-based inlaid self-lubricating sliding plates are particularly suitable for applications involving low-speed, reciprocating, or oscillating motions where oil film formation is difficult. During the opening and closing of the die, these sliding plates continuously provide lubrication to the moving components, preventing jamming and improving the efficiency and reliability of the die. For example, in some small stamping dies operating at opening and closing frequencies ranging from a few to several dozen times per minute, the self-lubricating properties of copper-based inlaid self-lubricating sliding plates can meet their lubrication needs without requiring frequent refueling and maintenance.

III. Reducing Maintenance Costs of Automotive Stamping Dies

Traditional automotive stamping dies require regular maintenance of their lubrication systems during use, including adding lubricating oil, cleaning oil sumps, and other tasks. Copper-based inlaid self-lubricating sliding plates eliminate the need for oil supply devices, oil injection holes, and oil sump machining, significantly reducing manufacturing costs. Moreover, by reducing the use of lubricating oil, they not only save on lubricant expenses but also eliminate the risks associated with insufficient oil supply, thereby lowering equipment maintenance costs. Over the entire service life of automotive stamping dies, the use of copper-based inlaid self-lubricating sliding plates can significantly reduce maintenance costs and improve production efficiency.

English

English Español

Español

Contact Us