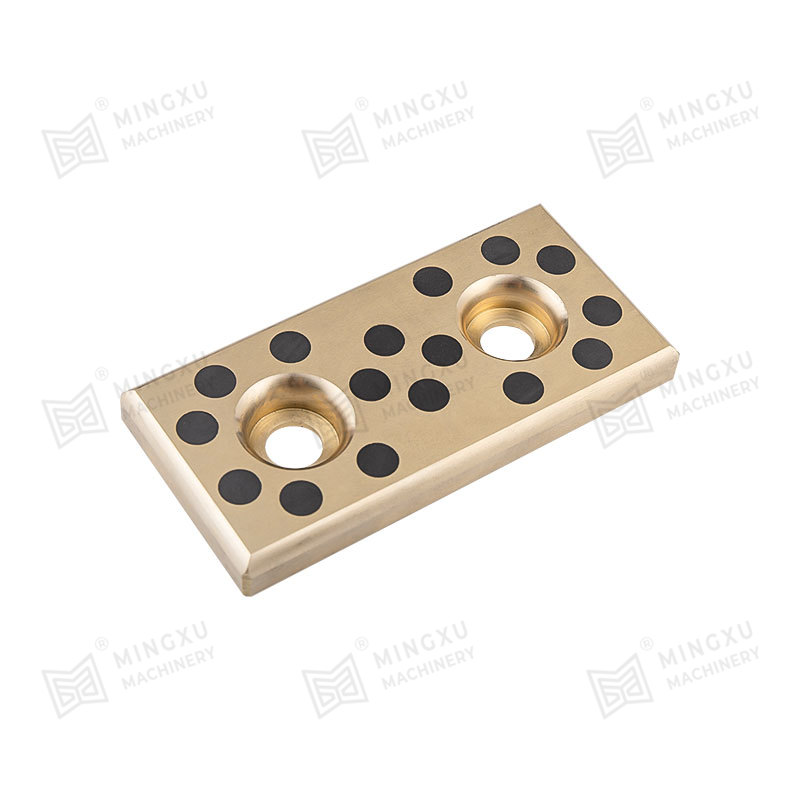

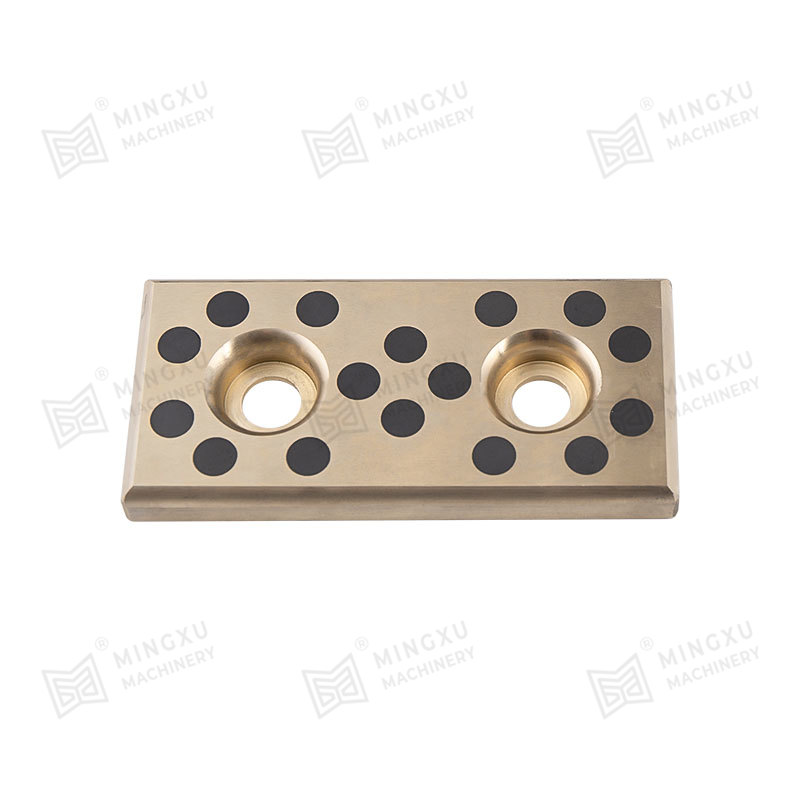

Mining machinery and equipment are very easy to wear during use. In order to extend the service life of the equipment, Mingxu Machinery recommends that you use MXB-JTSW wear-resistant copper plates to make lining plates to protect damaged machinery. MXB-JTSW wear-resistant plates have high hardness, are resistant to friction and impact, can be machine-cut or gas-cut, are easy to weld, and can meet the wear-resistant requirements of mining machinery under various working conditions.

-

1 Can work for a long time under oil-free conditions.

-

2 More suitable for low-speed and heavy-load workingconditions, with good wear resistance and extremely low frict.

-

3 Suitable for situations where oil film is difficult to form, such as reciprocating, rotating and intermittent movements.

-

4 Resistant to corrosion and oxidation.

-

5 Maintenance-free and long service life.

-

Reduce Manufacturing costs

There is no need for oil supply device, oil injection hole or oil groove processing, which can greatly save manufacturing costs.

-

Reduce Operating Costs

It greatly reduces the usage of lubricating oil, reduces equipment maintenance, and avoids hidden dangers caused by insufficient oil supply, effectively reducing operating costs.

-

Shorten Design Time

The oil-free design simplifies the product structure and effectively saves design time. We are professional ODM Suppliers of JTSW 20mm Copper alloy Wear Plate For Mining Equipment

-

Conducive To Environmental Protection

No waste oil recycling is required, which is also beneficial to environmental protection.

-

High Temperature

·Steel factory

·Smelting furnace

·Drying equipment

·Baking oven

·Heat controller

-

Water Proof

·Dam gate

·Water pump

·Fluid switch structure

·Offshore structures

·Dock and silt machine equipment

-

Chemical Industry

·Chemical factory

·Electroplating equipment

·Wastewater treatment equipment

·Dyeing machinery

·Oil and chemical refining equipment

-

Energy

·Wind power

·New energy

-

Ship

·Deck crane

·Anchor

·Hatch cover

·Rudder arm

·Lifting machinery and lifting ring equipment

-

Automobile Manufacturing

·Stamping mold

·Welding structure

·Painting and drying line

·Metal conveyor belt

·Machine tools

-

Heavy Industry

·Steel pipe factory machinery

·Tire and paper mills

·Power plant

·Connecting toggle of mold injection machinery

-

Construction, Mining, Loading

·Mixers, grinders, pulverizers

·Construction machinery

·Mining equipment

·Connecting rod bearings

-

Bridges and Lift Rails

·Bridge bearings

·Beams, bridges, suspension bridges

·Nuclear energy related reactors

·Steam generator

English

English Español

Español