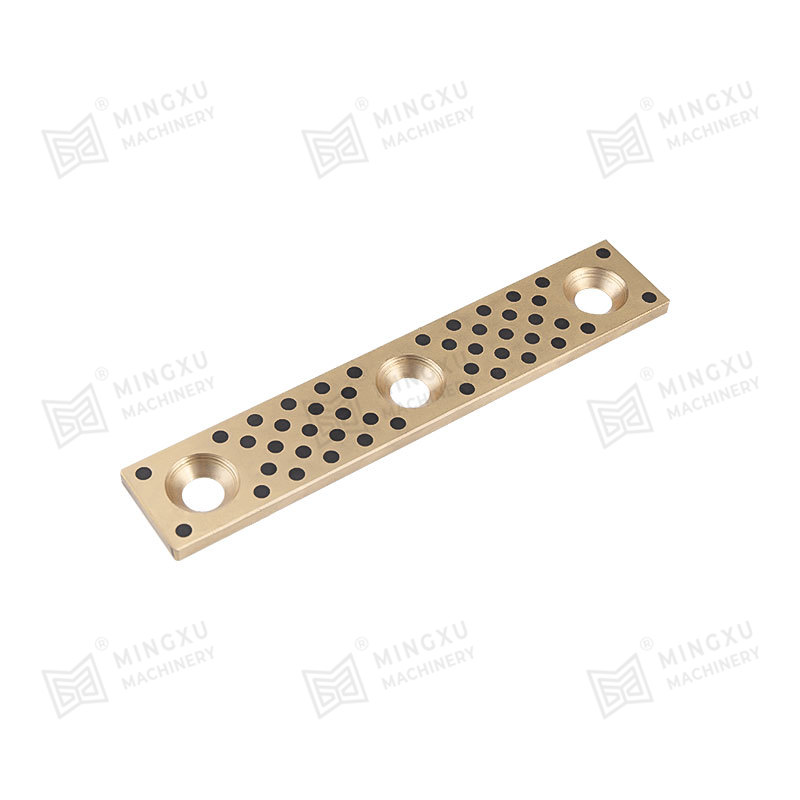

MXB-DUF Oil-Free Flange Composite Bearings

Cat:Oilless Bearing

The MXB-DUF oil-free composite bearing, also known as the SF-1F bushing, is a three-layer composite structure bearing. It typically consists of a stee...

See Details

The price of graphite copper bushings (also known as self-lubricating copper bushings or inlaid graphite copper bushings) is influenced by numerous and complex factors, leading to significant price variations.

Preliminary Notes:

1.No "Standard Price": Discussing prices without specific details on specifications, quantity, material, and process is meaningless.

2.The Four Core Elements: Material composition (especially copper alloy grade), dimensional specifications, machining accuracy, and procurement quantity are the four pillars affecting the price.

I.Basic Specification Parameters

Dimensions:

Inner diameter, outer diameter, length/height: Larger dimensions consume more raw materials, leading to higher prices. This is the most fundamental and direct cost factor.

Wall thickness: Thicker walls require more material, increasing costs.

Shape complexity: Standard cylindrical shapes are the most cost-effective. Complex structures with flanges, turned edges, lips, irregular holes, or special grooves require additional machining processes (such as turning, milling), significantly increasing costs and prices.

Accuracy and Tolerance Requirements:

Dimensional tolerances (inner diameter, outer diameter, length): Stricter tolerance requirements (e.g., IT6, IT7 grades) increase machining difficulty and may raise the scrap rate, leading to higher prices.

Geometric tolerances (roundness, cylindricity, concentricity, parallelism, etc.): Higher requirements increase machining and inspection costs.

Surface roughness: When high friction performance is required, precision machining such as grinding may be necessary to achieve lower Ra values (e.g., Ra0.8), increasing costs.

II.Material Factors (Core of Cost)

Copper Base Alloy Grade and Composition:

Specific grades of "high-strength brass": Different grades have significant cost differences. Common high-strength wear-resistant brass grades include:

Domestic: ZCuZn25Al6Fe3Mn3. The content of aluminum, iron, and manganese affects strength and wear resistance, as well as cost.

Imported/International: C86300 (manganese bronze), C93200 (high-lead tin bronze - although not called high-strength brass, it is sometimes used in self-lubricating bearings), C95400/C95500 (aluminum bronze), etc. Imported materials are usually more expensive.

Raw material purity and quality: The purity of electrolytic copper, alloy elements, and the smelting process affect material performance and cost.

Material standards: Compliance with different standards such as national (GB), American (ASTM/SAE), German (DIN), or Japanese (JIS) standards involves varying component requirements and inspection criteria, leading to cost differences.

Graphite Characteristics and Incorporation Method:

Graphite content: Higher content improves self-lubrication but may slightly reduce the base material's strength. The content needs to be optimized, and different contents affect costs.

Graphite morphology and distribution:

Inlaid/pressed: Drilling specific positions on the working surface of the copper bushing and pressing in solid graphite columns/balls. This method provides more durable lubrication but involves complex machining processes, significantly increasing costs compared to uniform mixing methods.

Graphite quality: Different types and purities of graphite, such as flake graphite and synthetic graphite, have different prices.

III. Manufacturing Process and Quality Requirements

Production Process:

Sand casting: Suitable for complex or large-sized shapes, it is the mainstream process.

Centrifugal casting: Provides higher density and better performance but at a slightly higher cost.

Continuous casting: Suitable for large-batch, regularly shaped copper parts with high material utilization rates. However, the mold cost is high, making it uneconomical for small batches.

Machining process complexity: The more complex the processes (such as turning, drilling for graphite inlay, milling for oil grooves/flanges, grinding for high-precision requirements, deburring), the higher the cost.

Quality Assurance and Inspection:

Inspection items: Full-dimensional inspection, hardness testing, metallographic analysis, non-destructive testing (e.g., ultrasonic), friction and wear testing, etc. More extensive and stringent inspection items increase costs.

Quality certifications: Suppliers with ISO 9001 or other quality management system certifications, or products needing to comply with specific industry standards (such as automotive, aviation, military), incur higher management and inspection costs.

Heat Treatment: Some high-strength brass requires heat treatment (such as solution treatment + aging) to achieve optimal mechanical properties, adding processes and costs.

Surface Treatment: Usually, no additional surface treatment is required (graphite provides lubrication). Special requirements such as tin plating, nickel plating, or oxidation treatment will incur additional costs.

IV. Procurement and Market Factors

Procurement Quantity:

This is one of the most critical factors affecting unit price! The batch effect is extremely significant.

Large batches: Can dilute fixed costs such as mold fees, equipment setup fees, and management fees, leading to very low unit prices (possibly more than 50% lower than small batches).

Small batches/single pieces: Fixed costs account for a high proportion, making unit prices very expensive.

Procurement Channels:

Manufacturer direct sales: Professional manufacturers like Mingxu Bearing usually offer the lowest prices (especially for large batches), but may have minimum order quantity requirements.

Agents/distributors: Provide convenience (small batches, spot goods, technical support), but prices include service fees and are higher than direct manufacturer sales.

Traders/online platforms: Facilitate price comparison and procurement of standard products with high price transparency, but attention should be paid to the source and quality of goods.

Brand Premium:

Well-known brands (such as Oiles, GGB, Zhongda Bearing, Changsheng Bearing, etc.) usually command higher prices than ordinary or unbranded products due to technology, quality, reputation, and service.

Raw Material Market Price Fluctuations:

Copper, tin, aluminum, nickel, etc., are the main raw materials, and their international futures and spot price fluctuations directly affect the raw material costs of copper bushings. Copper price fluctuations are particularly significant.

Supply and Demand Relationship:

When market demand is strong or specific specifications are in short supply, prices may rise.

Transportation costs, energy costs, tariffs, etc., also affect the final price.

Lead Time:

Expedited delivery may require additional fees.

Summary and Inquiry Suggestions

No "Standard Price": Discussing prices without specific details on specifications, quantity, material, and process is meaningless.

The Four Core Elements: Dimensional specifications, material composition (especially copper alloy grade and graphite incorporation method), machining accuracy, and procurement quantity are the four pillars affecting the price.

How to Obtain an Accurate Quote?

Provide detailed drawings: Include all dimensions, tolerances, geometric tolerances, roughness, material requirements (grade!), and technical standards.

Or specify key parameters: Inner diameter x outer diameter x length, material grade (e.g., must be ZCuZn25Al6Fe3Mn3), graphite type (turned/pressed), precision grade, and required quantity.

Obtain multiple quotes: Provide identical inquiry information to at least 3-5 reliable suppliers (mainly manufacturers, as intermediaries may have higher markups) for price comparison.

Focus on total cost: When comparing unit prices, always consider factors such as minimum order quantity, payment terms, lead time, freight, taxes, quality assurance, and after-sales service.

If you can provide specific dimensions, material grades, and procurement quantities, I can help analyze the approximate price range or provide more precise quotation guidance.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the R&D and production of copper alloy components and self-lubricating bearings for over a decade, with rich production experience and technical accumulation. For any product or technical inquiries, please feel free to contact us at [email protected].

The MXB-DUF oil-free composite bearing, also known as the SF-1F bushing, is a three-layer composite structure bearing. It typically consists of a stee...

See Details

MXB-DX boundary oil-free bearings, equivalent to SF-2 self-lubricating or dry plain bearings, which is based on steel plate, sintered spherical bronze...

See Details

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JOLP self-lubricating wear plates have good self-lubricating properties and require no external lubrication. This product has good load-bearing ca...

See Details

Circular guides are frequently used in automobile panel molds and large stamping molds. The mold base and unloading plate guides usually use self-lubr...

See Details

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MX2000-2 nickel graphite dispersed alloy bearing is a new product among solid lubricating bearings. Compared with TF-1, this product has the character...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

See Details

SF-1P reciprocating bearing is a novel formula product designed based on the structure of SF-1X material and according to the special common condition...

See Details

Contact Us