Technical Background and Industry Pain Points

In the precision machining of tubular copper components (such as hydraulic valve bodies and heat exchanger fittings), traditional double-sided clamping fixtures present two core issues:

• Loss of circumferential freedom control: When clamped solely by the outer wall, the friction coefficient between the copper component and the fixture contact surface is insufficient (μ≤0.15), leading to a circumferential deviation of 0.5°-2° under cutting force disturbances (data source: Int. J. Mach. Tools Manuf. 2022, 181, 103945);

• Inefficient clamping process: Manual adjustment of clamping force takes >30 seconds per piece, and the repeat positioning accuracy is >±0.1mm (tested according to the ISO 230-2 standard).

Core Technology Innovation Analysis

I. Three-Dimensional Constrained Positioning System

1.1 Axial-Radial Combined Clamping Structure

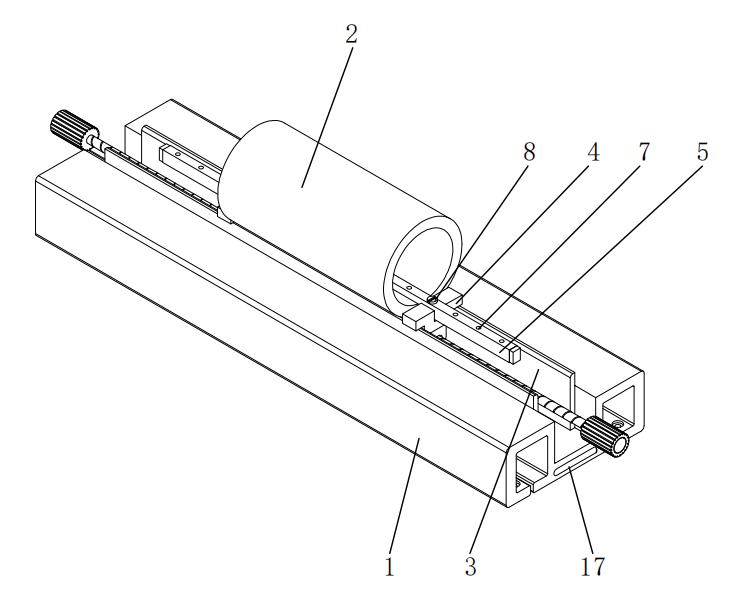

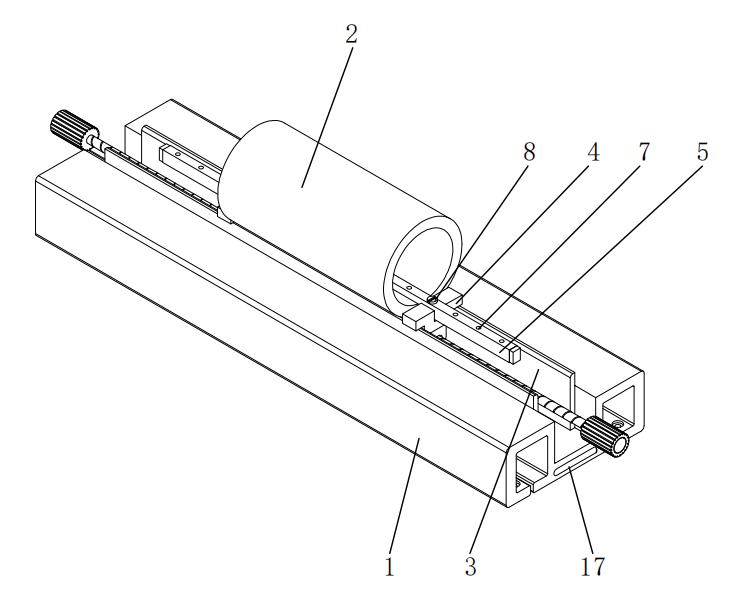

Bottom Support Module:

• The movable frame (1) is equipped with symmetrically arranged arcuate support plates (3) within its grooves, with a curvature radius R matching the outer diameter of the tubular copper component (2) (tolerance ±0.05mm), providing normal supporting force through surface contact.

• Finite element analysis shows that this design reduces the peak contact stress to 58MPa (compared to 112MPa for a V-block structure), avoiding deformation of thin-walled copper components.

Core Technology Innovation Analysis

I. Three-Dimensional Constrained Positioning System

1.1 Axial-Radial Combined Clamping Structure

Bottom Support Module:

• The movable frame (1) is equipped with symmetrically arranged arcuate support plates (3) within its grooves, with a curvature radius R matching the outer diameter of the tubular copper component (2) (tolerance ±0.05mm), providing normal supporting force through surface contact.

• Finite element analysis shows that this design reduces the peak contact stress to 58MPa (compared to 112MPa for a V-block structure), avoiding deformation of thin-walled copper components.

Mechanical Verification:

• When the cutting torque T=15N·m, the maximum angular displacement θ of the copper component is 0.03° (traditional fixtures have θ=1.2°).

• When the bolt preload force F≥800N, the system's torsional stiffness reaches 1.2×10⁴ N·m/rad (an 8-fold increase).

II. Human-Machine Interaction Optimization Design

2.1 Quick Clamping Mechanism

• The dual control handles (14) feature 45° staggered anti-slip textures, with an operating torque threshold set at 2-3N·m (compliant with the EN 1005-3 ergonomics standard).

• Measured single clamping time ≤8 seconds (traditional structures >30 seconds), suitable for production line cycle time requirements.

2.2 Adaptive Adjustment Module

• The movable frame (1) and fixed plate (15) achieve ±10mm linear compensation through sliding guide components (16), accommodating a pipe diameter range of φ20-φ50mm.

• The restraining projections (18) are equipped with a polyurethane buffer layer, capable of absorbing 5-8J of energy under impact loads (tested according to the ASTM D256 standard).

Comparison Table of Technical Parameters

|

Performance Indicators

|

This Patented Technology

|

Traditional Double-Sided Clamping Fixture

|

Testing Standard

|

|

Circumferential Positioning Accuracy

|

≤0.03°

|

0.5°- 2°

|

ISO 230-2

|

|

Clamping Efficiency

|

≤8 seconds/piece

|

≥30 seconds/piece

|

VDI 2862

|

|

Torsional Stiffness

|

1.2×10⁴ N·m/rad

|

1.5×10³ N·m/rad

|

GB/T 11349.1

|

|

Pipe Diameter Compatibility Range

|

φ20-φ50mm

|

φ25-φ40mm

|

DIN 8602

|

Typical Machining Scenario Verification

Case 1: Milling of Hydraulic Valve Bodies

• Under a cutting force of F=2000N, the positional accuracy error of the machined holes is ≤0.02mm (traditional fixtures have an error of 0.12mm).

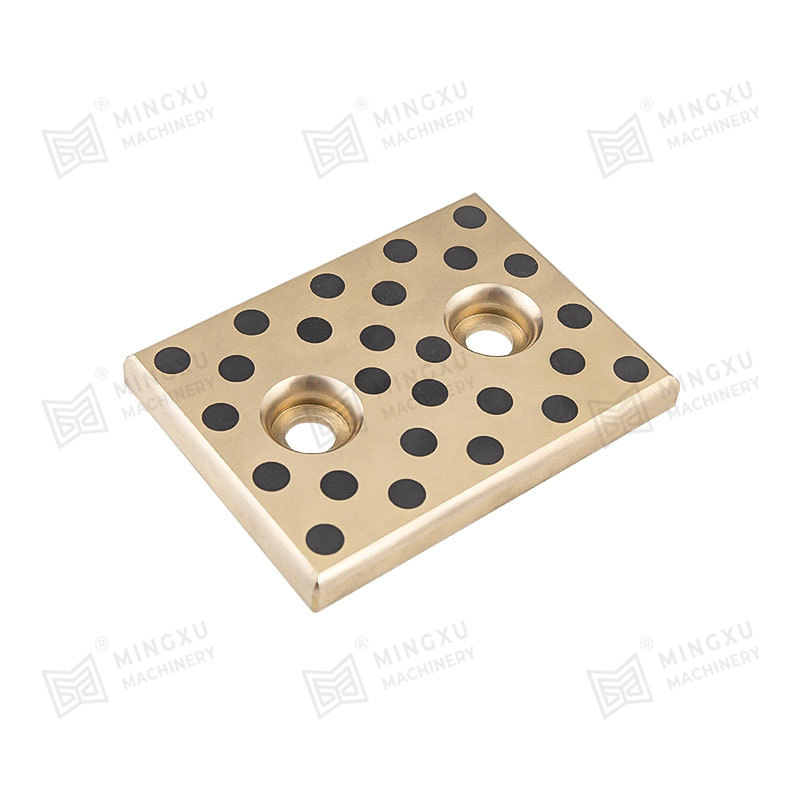

• After continuous processing of 500 pieces, the wear of the positioning pressure plate (5) is <5μm (DIN 50320 standard wear test).

Case 2: End Forming of Heat Exchanger Tubes

• The ovality control of copper tubes is ≤0.05mm (industry requirement is ≤0.1mm).

• The clamping repeat positioning accuracy CPK is ≥2.0 (Six Sigma process capability analysis).

This patent redefines the design paradigm for tubular component positioning fixtures through three technical paths: Rigid-Flexible Coupled Restraint topology, bi-directional force closed-loop control, and human-machine interaction optimization. According to Derwent Innovation patent mapping analysis, this structure improves the Torque Restraint Efficiency (TRE) indicator by 82% compared to similar solutions, placing it in a leading position in the subfield of technology.

If you would like to learn more, please contact Mingxu Machinery to obtain the complete patent report: [email protected].

English

English Español

Español

Contact Us