MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

Content

Flanged (Stop-Collar) Design

Self-Lubrication Mechanism

Base Material

Key Performance Parameters

High Load Capacity and Wear Resistance

Maintenance-Free and Environmentally Friendly

Corrosion Resistance and Wide Temperature Range Adaptability

Shaft Material Selection

Assembly Methods

Maintenance Considerations

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

JTWN thrust washers adopt self-lubricating inlay technology, which further improves self-lubricating performance based on its high strength and wear r...

See Details

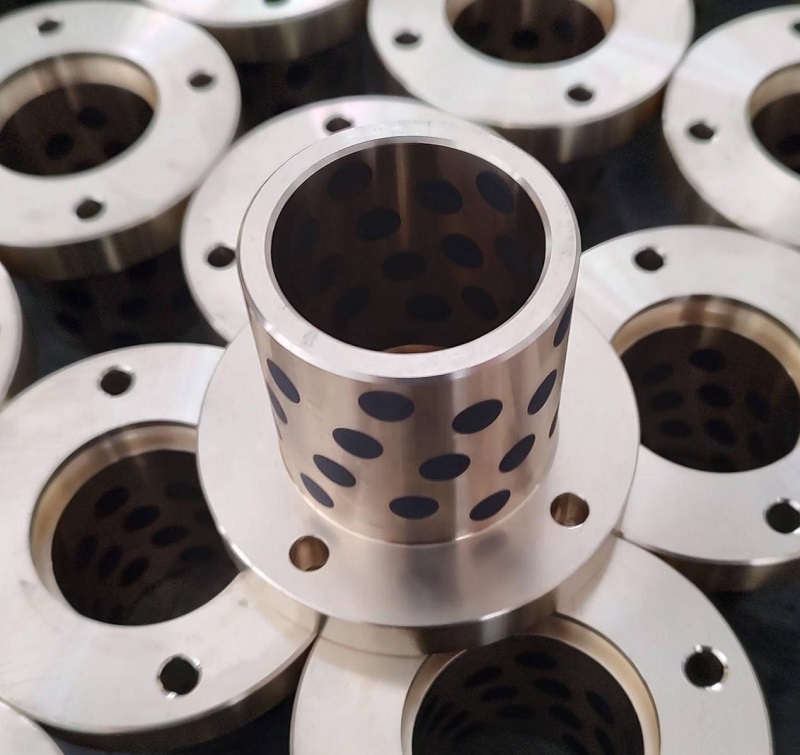

MXB-JDBUF self-lubricating casting bronze bearings combine the advantages of self-lubricating and flange design. The raw materials are made of high-qu...

See Details

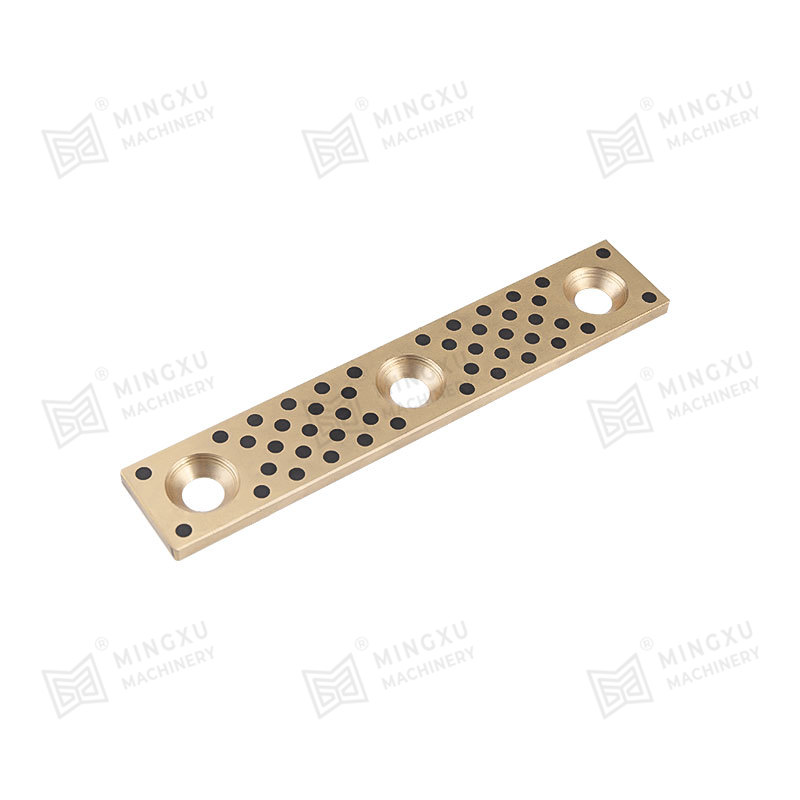

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JOLP self-lubricating wear plates have good self-lubricating properties and require no external lubrication. This product has good load-bearing ca...

See Details

MGB9834 DIN9834 standard guide bushing complies with DIN9843 standard and is suitable for European automotive stamping dies. It is designed to provide...

See Details

MSEW JIS 20mm Standard Wear Plate is based on high-strength brass, tin bronze, steel-copper bimetal, cast iron or bearing steel. The surface is inlaid...

See Details

Normally, the push plate is supported by four reset rods. However, due to the low installation accuracy of the reset rods, when the push plate is larg...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us