Content

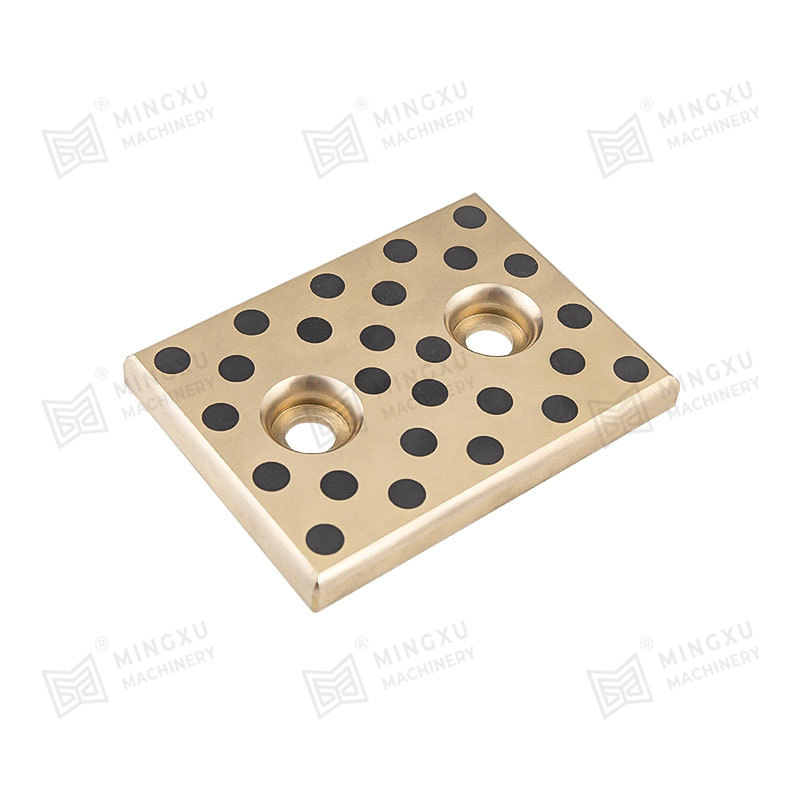

ZRHH Self-Lubricating Thrust Bearings

ZRHH self-lubricating thrust bearings are high-performance sliding bearings manufactured by Zhejiang Mingxu Machinery Manufacturing Co., Ltd. The base layer typically uses high-strength copper alloys such as ASTM C86300, high-force brass (ZCuZn25Al6Fe3Mn3), or similar engineered alloys. These copper-based materials provide excellent mechanical strength, impact resistance, and corrosion resistance, enabling reliable bearing performance under demanding operating environments.

The tribological performance characteristics of ZRHH brass-based self-lubricating bearings include the following dimensions:

Low Friction Coefficient

Solid lubricants such as graphite and molybdenum disulfide are embedded into the brass alloy matrix. During operation, these solid lubricants gradually release fine lubricant particles that form a lubricating film on the contact surface. This significantly reduces the friction coefficient, decreases frictional resistance between components, lowers energy consumption and heat generation, and improves operational efficiency.

Wear Resistance

Copper alloys inherently possess favorable wear resistance. When integrated with solid self-lubricating additives, wear resistance is further enhanced. Even without external lubrication or under harsh service environments, ZRHH bearings maintain low wear rates, extending working life and reducing component replacement frequency.

Load-Bearing Capacity

The copper alloy base exhibits high strength and rigidity. This allows the bearing to sustain substantial mechanical loads without plastic deformation, ensuring mechanical stability and reliability during high-load operation.

Boundary Lubrication Performance

During start-up or low-speed operation, embedded lubricants directly participate in the friction interface, forming a boundary lubrication layer. This prevents direct metal-to-metal contact, mitigating adhesive wear and improving early-stage operating smoothness.

Wide Environmental Adaptability

ZRHH self-lubricating materials are capable of stable operation across a wide range of environments, including high and low temperatures, vacuum environments, and corrosive media. Their adaptability supports application in complex industrial equipment and environments with lubrication constraints.

Maintenance-Free or Low-Maintenance Operation

The internal solid lubrication system reduces dependency on external lubrication infrastructure. This decreases maintenance cycles and operational cost, particularly benefiting equipment in remote, sealed, or difficult-to-maintain locations.

Operational Stability and Reliability

During extended operation, ZRHH bearings maintain a stable low friction coefficient. Stick-slip behavior is largely avoided, ensuring smooth movement control and supporting precision-critical industrial applications.

Conclusion

ZRHH brass-based self-lubricating bearings demonstrate advanced tribological characteristics, including reduced friction losses, enhanced wear resistance, high load-bearing capacity, and strong environmental adaptability. These properties position them as high-performance bearing solutions for modern industrial machinery. For detailed material specifications and engineering parameters, contact Zhejiang Mingxu Machinery Manufacturing Co., Ltd. or consult the corresponding technical documentation.

Contact: [email protected]

English

English Español

Español

Contact Us