A self-lubricating bearing is a type of bearing designed to operate without external lubrication. It incorporates lubricating materials—such as graphite, PTFE, or oil-impregnated bronze—within its structure, allowing smooth operation even under high loads or extreme conditions. These bearings are widely used in machinery where maintenance access is difficult or where long-term, consistent performance is critical.

The internal lubrication system forms a thin film between the bearing surface and the shaft, significantly reducing friction and wear. As a result, self-lubricating bearings extend service life, minimize maintenance requirements, and maintain efficiency across a wide temperature and load range.

2. How Self-Lubricating Bearings Work

These bearings rely on materials with inherent lubricating properties or on micro-pores filled with lubricants. During operation, the motion and heat cause the lubricant to migrate to the bearing surface, forming a consistent lubrication layer. When the machinery stops, the lubricant is reabsorbed into the bearing material, making the system self-sustaining over repeated cycles.

2.1 Lubrication Mechanisms

- Solid lubricant dispersion — graphite or PTFE particles evenly distributed within a metal or polymer matrix release lubricant gradually during friction.

- Oil impregnation — porous metals are soaked in lubricating oil, which is released when temperature rises during operation.

- Composite layering — multiple layers of materials combine structural strength with self-lubricating surfaces.

3. Common Types of Self-Lubricating Bearings

| Type |

Material Composition |

Typical Applications |

| Oil-Impregnated Bronze Bearing |

Sintered bronze with internal oil reservoirs |

Electric motors, fans, pumps |

| PTFE-Lined Composite Bearing |

Steel backing with PTFE sliding layer |

Hydraulic cylinders, automotive joints |

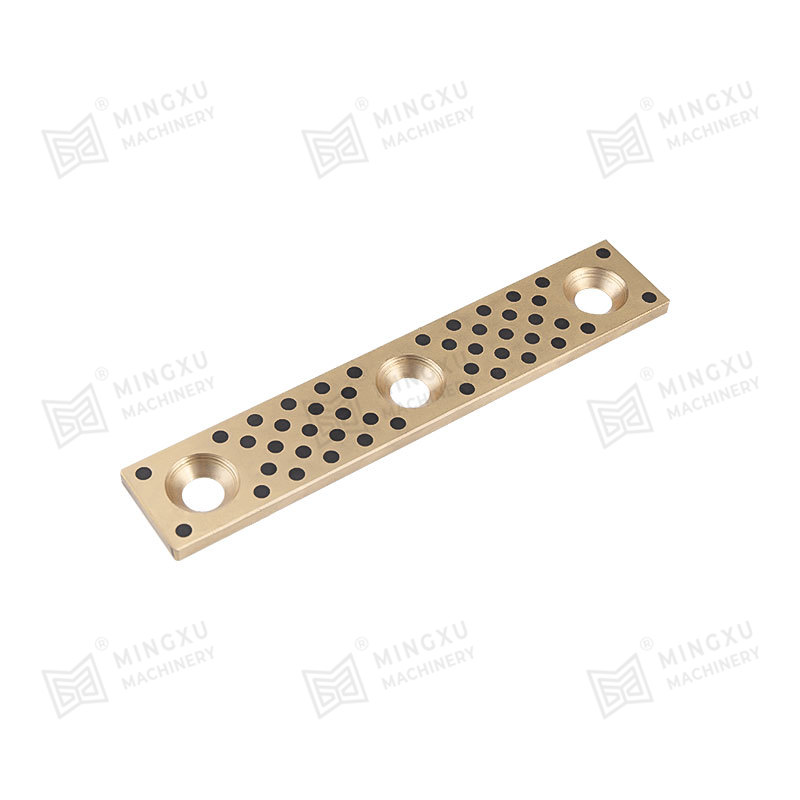

| Graphite Plugged Bearing |

Cast bronze or brass with embedded graphite plugs |

Heavy-duty presses, cranes, molds |

| Polymer-Based Bearing |

High-performance plastics such as POM or nylon with solid lubricants |

Food processing, packaging, and light mechanical systems |

4. Key Advantages of Self-Lubricating Bearings

- Maintenance-free operation — eliminates the need for periodic oiling or greasing, reducing downtime.

- Extended lifespan — continuous lubrication minimizes friction and wear, improving durability under harsh conditions.

- Clean and environmentally friendly — no external lubricant leakage, suitable for cleanroom or food-grade equipment.

- Stable performance under varying loads and temperatures — suitable for high-load and intermittent operation environments.

5. Typical Applications Across Industries

Due to their reliability and self-sufficiency, self-lubricating bearings are used in a wide range of industrial and mechanical applications. Their versatility makes them suitable for environments where lubrication is difficult or undesirable.

- Automotive: suspension joints, steering systems, pedal assemblies.

- Construction equipment: cranes, loaders, and hydraulic pivots operating under dust or mud conditions.

- Aerospace and defense: high-temperature, low-maintenance mechanical joints and actuators.

- Renewable energy systems: wind turbine blade pitch control and solar tracking systems.

- Food and packaging: clean, lubricant-free performance preventing contamination.

6. Selection Tips for Engineers and Designers

Choosing the correct self-lubricating bearing depends on load, speed, operating temperature, and environment. Below are practical considerations to ensure optimal performance and cost-effectiveness.

- Evaluate operating load and sliding speed (PV value) — higher loads and speeds may require metal-based composites.

- Check environmental conditions — moisture, chemicals, or dust may dictate material choice such as polymer vs. bronze.

- Confirm temperature range — PTFE or graphite types handle higher temperatures than polymer bearings.

- Assess tolerance requirements — composite bearings can accommodate misalignment better than traditional types.

7. Maintenance and Performance Optimization

7.1 Inspection and Replacement

Even though self-lubricating bearings are designed for long-term operation, periodic inspection for wear or corrosion ensures consistent performance. Replace bearings showing signs of deformation, excessive clearance, or surface scoring.

7.2 Installation Best Practices

- Press-fit bearings evenly to avoid distortion of the housing or bearing shell.

- Clean all mating surfaces thoroughly before assembly to prevent contamination that may affect lubrication film formation.

- Avoid over-tightening bolts or fasteners that could cause misalignment or excessive preload.

8. Summary

Self-lubricating bearings provide an effective, low-maintenance solution for mechanical systems requiring reliable and consistent movement. Their ability to reduce friction without external grease or oil makes them indispensable in modern engineering applications. By understanding the materials, structure, and selection principles, engineers can achieve longer service life, lower maintenance costs, and improved machine efficiency.

English

English Español

Español

Contact Us