Self-lubricating wear plates are specially designed components widely used in machinery to reduce friction, extend service life, and improve operational efficiency. While their primary purpose is to minimize wear and maintenance, they also have a notable impact on noise reduction and vibration control in various types of equipment. Understanding how these plates work and their benefits in noise and vibration management can help industries optimize machinery performance.

1. How Self-Lubricating Wear Plates Work

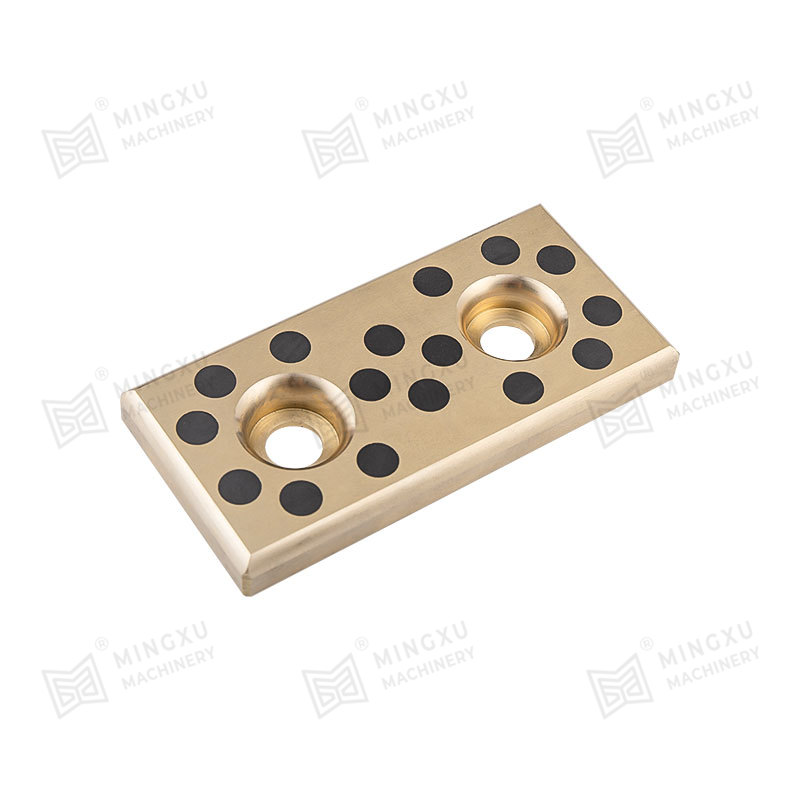

A self-lubricating wear plate typically consists of a high-strength polymer or composite material impregnated with solid lubricants such as PTFE (polytetrafluoroethylene), graphite, or molybdenum disulfide. These lubricants are embedded within the matrix of the plate, allowing the surface to provide continuous lubrication without the need for external grease or oil.

By reducing direct metal-to-metal contact between moving components, the plate decreases frictional forces, which are a primary source of heat, wear, and mechanical vibration. This built-in lubrication system ensures smoother motion, reducing the irregularities that can cause noise in machinery.

2. Noise Reduction Benefits

Noise in industrial equipment is often caused by metal-to-metal contact, friction, and impact between moving parts. Self-lubricating wear plates address these sources in several ways:

- Friction Reduction: The embedded lubricant creates a smooth sliding interface, which reduces the grinding or squeaking sounds that occur in traditional unlubricated contact points.

- Impact Damping: The composite materials used in wear plates can absorb minor shocks and impacts, softening the contact between heavy components.

- Consistent Lubrication: Unlike traditional lubrication, which can degrade or run out, self-lubricating plates provide continuous low-noise operation over long periods, maintaining quieter machinery performance.

Industries such as automotive manufacturing, heavy machinery, and material handling frequently observe measurable noise reduction after switching to self-lubricating wear plates.

3. Vibration Control Advantages

Vibration in machinery is closely linked to friction and uneven movement. Excessive vibration can lead to component fatigue, reduced efficiency, and accelerated wear. Self-lubricating wear plates help mitigate these issues by:

- Smoothing Motion: Continuous lubrication reduces jerky movement and irregular sliding, lowering vibration amplitudes.

- Shock Absorption: The polymer or composite structure of the plate absorbs minor mechanical shocks, preventing them from propagating through the system.

- Reducing Metal Fatigue: By minimizing direct metal-to-metal contact, the plates prevent repeated micro-impacts that can lead to vibration over time.

This vibration reduction not only improves machine longevity but also enhances operator comfort and safety, especially in environments with high-speed or repetitive motion equipment.

4. Applications Where Noise and Vibration Reduction Matter

Self-lubricating wear plates are particularly valuable in equipment where noise and vibration control is critical, such as:

- Conveyor Systems: Reducing sliding friction between rollers or guide rails to maintain smooth, quiet operation.

- Industrial Presses and Molds: Minimizing impact noise and vibration during repetitive pressing or forming cycles.

- Agricultural Machinery: Reducing vibration in equipment like harvesters or plows for longer component life and operator comfort.

- Material Handling Equipment: Forklifts, cranes, and hoists benefit from smoother motion and reduced operational noise.

- Marine and Offshore Equipment: Providing quiet and smooth operation in high-load, high-moisture environments.

In all these applications, the combination of reduced friction, shock absorption, and continuous lubrication makes self-lubricating wear plates an effective solution for both maintenance and operational performance.

5. Additional Benefits

Besides noise and vibration reduction, self-lubricating wear plates offer several other advantages:

- Maintenance-Free Operation: No need for external lubrication, reducing downtime and labor costs.

- Extended Service Life: Reduced wear and tear prolongs the lifespan of both the wear plate and the mating components.

- Temperature and Corrosion Resistance: Many wear plates are designed to withstand harsh environments, maintaining their noise and vibration damping properties under stress.

These additional benefits complement the noise and vibration reduction, making self-lubricating wear plates a multifunctional component in modern machinery.

Conclusion

Self-lubricating wear plates can significantly reduce noise and vibration in equipment by providing continuous lubrication, smoothing motion, and absorbing minor impacts. Their polymer or composite construction ensures long-lasting performance, even in high-load, high-friction, or harsh environments. By reducing frictional noise and mechanical vibrations, these wear plates improve operator comfort, machine efficiency, and component lifespan.

For industries seeking quieter, smoother, and more reliable equipment operation, investing in self-lubricating wear plates offers both immediate and long-term benefits, combining maintenance-free convenience with enhanced performance.

English

English Español

Español

Contact Us