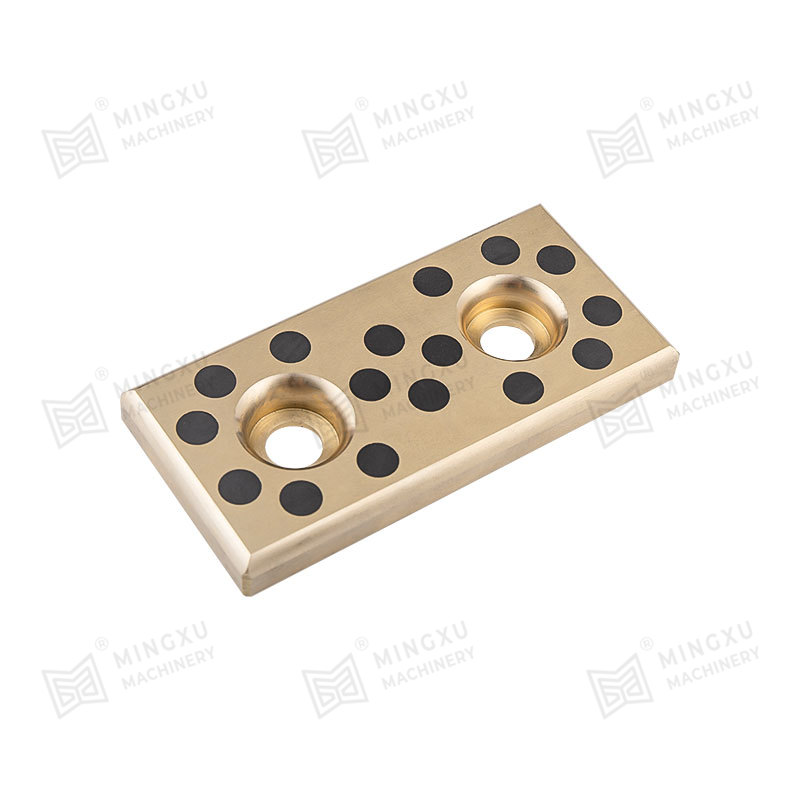

MXB-JFFB Self-Lubricating Half Bearing

Cat:Self-Lubricating Bearing

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See DetailsMaintenance-free bearings are designed to operate reliably over long periods without the need for regular lubrication or intensive upkeep. These bearings are commonly used in applications ranging from household appliances and office equipment to industrial machinery and automotive components. While they offer significant convenience and cost savings, their performance can still be influenced by temperature extremes and environmental exposure. Understanding these factors is crucial for selecting the right bearing and ensuring long-term operational reliability.

Content

High Temperatures:

Excessive heat can affect the internal lubricant and materials used in maintenance-free bearings. Many of these bearings use pre-lubricated grease sealed inside the bearing unit. When exposed to high temperatures, the grease can break down or lose viscosity, reducing its ability to minimize friction. Prolonged high-heat exposure may also cause expansion or deformation of bearing components, potentially leading to premature wear or failure.

Low Temperatures:

Extreme cold can increase the viscosity of the grease inside maintenance-free bearings, making the bearing feel stiff and harder to rotate. In severe cases, the lubricant may solidify, causing increased friction and potential operational delays. Bearings intended for low-temperature applications often use specially formulated lubricants to remain effective in sub-zero conditions.

Thermal Cycling:

Repeated heating and cooling cycles, common in outdoor or industrial environments, can also affect bearing performance. Thermal expansion and contraction of the bearing components may stress seals or cause slight dimensional changes, which can affect smooth rotation over time. Selecting bearings designed to withstand thermal cycling is critical for applications with frequent temperature fluctuations.

Moisture and Water:

While many maintenance-free bearings come with sealed designs to protect against moisture, prolonged exposure to water, high humidity, or condensation can compromise the seals. This may allow water to enter, diluting the internal lubricant and accelerating corrosion of metal components. Bearings intended for wet environments often feature water-resistant or stainless-steel materials to maintain long-term reliability.

Dust, Dirt, and Debris:

In dusty or dirty environments, contaminants can enter the bearing if the seal is damaged or insufficient. Even maintenance-free bearings are not completely impervious to abrasive particles, which can cause accelerated wear and reduce bearing life. Bearings designed for harsh environments typically include enhanced sealing, shields, or covers to prevent contamination.

Corrosive or Chemical Exposure:

Maintenance-free bearings used in industrial settings may encounter chemicals, acids, or salts that can corrode standard steel components. Selecting bearings with corrosion-resistant materials such as stainless steel or coated surfaces helps maintain performance under these conditions. The internal lubricant should also be compatible with any chemical exposure to prevent degradation.

To maximize the lifespan and efficiency of maintenance-free bearings under varying environmental conditions:

Manufacturers often provide specifications including temperature limits, IP ratings (for dust and water resistance), and chemical compatibility to guide proper selection. Following these recommendations ensures the bearing maintains smooth operation and reliability even under challenging conditions.

Even with temperature and environmental factors affecting performance, maintenance-free bearings remain highly advantageous:

While maintenance-free bearings are designed to operate without regular lubrication, their performance can be influenced by temperature extremes and environmental exposure. High or low temperatures, moisture, dust, and chemical exposure can all affect the internal lubricant, seals, and bearing materials. By understanding these factors and selecting bearings with the appropriate lubricant type, sealing, and material composition, users can ensure long-lasting, reliable operation even in demanding conditions.

Proper selection, installation, and awareness of environmental limitations allow maintenance-free bearings to deliver their core benefits: reduced maintenance, durability, and operational efficiency.

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See Details

Mining machinery and equipment are very easy to wear during use. In order to extend the service life of the equipment, Mingxu Machinery recommends tha...

See Details

MXB-JTLP self-lubricating wear-resistant plate can provide standard products ranging from width from 18mm to 68mm and length from 100mm to 220mm. It c...

See Details

MXB-JGLX self-lubricating guide rails cover multiple properties such as high wear resistance, high temperature resistance, corrosion resistance, etc.,...

See Details

Constructed from high-grade graphite-copper alloy, the MXB-JSL L-type self-lubricating guide rail is strategically installed at the mold clamping guid...

See Details

Normally, the push plate is supported by four reset rods. However, due to the low installation accuracy of the reset rods, when the push plate is larg...

See Details

The bimetallic slide plate with wear-resistant alloy sintered on three sides is a new type of self-lubricating plate. Compared with the general single...

See Details

SF-1X oil-free lubricating bearing is a rolled sliding bearing with steel plate as the base, spherical bronze powder sintered in the middle, and a mix...

See Details

SF-1W lead-free bearing is a new product developed based on SF-1X material according to international environmental protection requirements. In additi...

See Details

The SF-2S oil-free bearing, as an upgrade to the SF-2 series, stands out with its unique design concept and excellent performance. It features a solid...

See Details

Contact Us