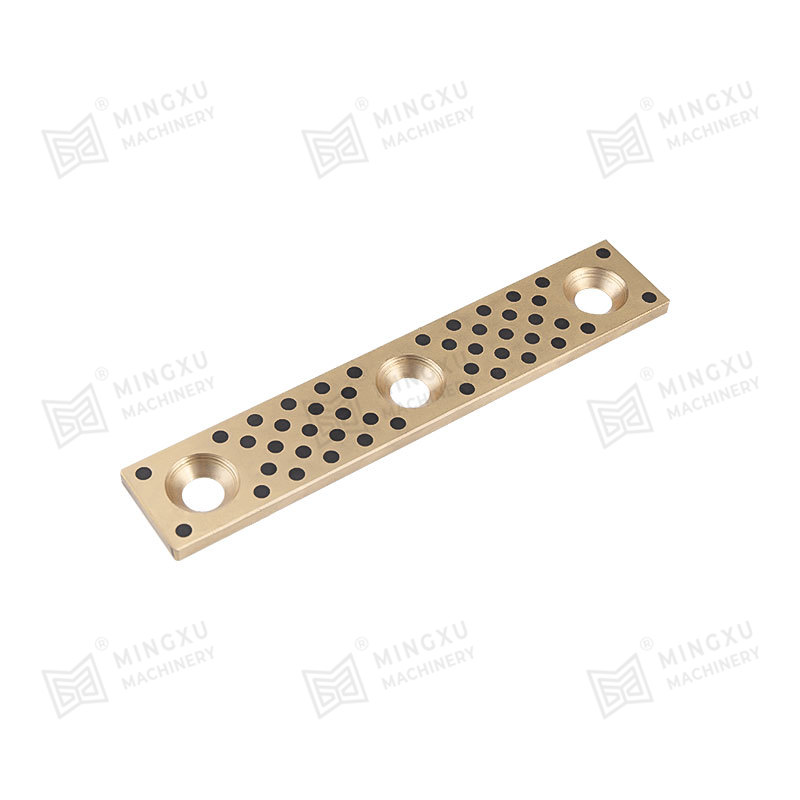

MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See DetailsThe Bronze-Based Solid Inlaid Self-Lubricating Spherical Bearing offers several distinct tribological advantages over conventional lubricated bearings, particularly in applications involving oscillating or angular motion where lubrication challenges are more pronounced. These advantages stem from both the inherent properties of the bronze alloy and the integration of solid lubricant materials into the bearing structure.

In traditional lubricated bearings, the formation of a hydrodynamic or elastohydrodynamic film is essential to minimize direct metal-to-metal contact. However, in oscillating or reciprocating motion—where the movement is limited in angle and speed—this lubricating film often breaks down or fails to form altogether. This leads to increased friction, wear, and ultimately, reduced service life. Conventional lubricants such as oils and greases can also degrade over time due to oxidation, contamination, or evaporation, particularly in high-temperature or inaccessible environments, necessitating regular maintenance.

In contrast, Bronze-Based Solid Inlaid Self-Lubricating Spherical Bearings are designed to function effectively under such conditions without the need for external lubrication. These bearings consist of a bronze alloy matrix, often using materials such as tin-bronze or aluminum-bronze for their high strength, corrosion resistance, and thermal conductivity. Into this bronze matrix, solid lubricant plugs—typically made of graphite, molybdenum disulfide (MoS₂), or polytetrafluoroethylene (PTFE)—are embedded in a uniform and strategically distributed pattern.

As the bearing operates, the solid lubricant is gradually transferred from the inlaid plugs to the contact surfaces through a self-replenishing mechanism. This process ensures a consistent, low-friction interface even under dry running conditions or during start-stop motion. In angular or oscillating movement, where boundary lubrication dominates and where traditional lubricants might be wiped away or fail to redistribute effectively, the solid lubricant continues to function reliably. This greatly reduces the coefficient of friction and minimizes adhesive or abrasive wear mechanisms.

Another significant advantage is the bearing’s ability to operate in environments where conventional lubricants are not feasible, such as in high-temperature settings, vacuum applications, or areas where contamination by oil or grease must be avoided (e.g., food processing or cleanrooms). The bronze base provides mechanical strength and load capacity, while also allowing for effective heat dissipation, which helps prevent thermal degradation of both the bearing and the lubricant.

Furthermore, Bronze-Based Solid Inlaid Self-Lubricating Spherical Bearings are well-suited to compensate for misalignment and shaft deflection due to their spherical contact design. This geometry allows angular motion to occur while maintaining surface conformity and uniform stress distribution, which reduces localized wear and improves the overall stability of the system.

The primary tribological advantages of using Bronze-Based Solid Inlaid Self-Lubricating Spherical Bearings in oscillating or angular motion applications include maintenance-free operation, consistent lubrication without external grease or oil, resistance to lubricant loss under intermittent movement, superior performance under boundary lubrication, and extended service life under harsh operating conditions. These characteristics make them a preferred solution in sectors such as heavy machinery, hydraulic systems, construction equipment, aerospace components, and marine engineering—especially where reliability, durability, and reduced maintenance are critical.

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

FB090 bronze bearings are made of tin bronze alloy CuSn8. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according ...

See Details

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JTGLW self-lubricating guide rails provide resistance and reduce friction, ensuring extended durability and enhanced performance. This product pro...

See Details

MXB-JGLXS guide rails are parts installed on both sides of the side core-pulling slider to ensure that the side core-pulling slider moves back and for...

See Details

Constructed from high-grade graphite-copper alloy, the MXB-JSL L-type self-lubricating guide rail is strategically installed at the mold clamping guid...

See Details

MJGB oil-free injection guide bushings are standard components used in the plastic injection molding process, providing lubrication-free guidance and ...

See Details

SF-1W lead-free bearing is a new product developed based on SF-1X material according to international environmental protection requirements. In additi...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1D hydraulic bearing is a new type of material designed based on SF-1P and combining the working principle of oil cylinder and shock absorber. It i...

See Details

Contact Us