A boundary lubrication bearing is a type of bearing that operates under specific lubrication conditions, primarily relying on a chemical reaction film or physical adsorption film formed between certain components in the lubricating oil and the metal surface to achieve lubrication. Boundary lubrication bearings are widely used in multiple industrial fields due to their unique lubrication mechanism, efficient lubrication performance, excellent load-bearing capacity, as well as advantages such as low cost and long service life. Compared with self-lubricating bearings, boundary lubrication bearings differ in terms of lubrication methods, application scenarios, etc. Users should make reasonable choices based on specific usage conditions and equipment requirements.

I. Product Characteristics and Performance

l Unique Lubrication Mechanism: When boundary lubrication bearings are in operation, their surfaces react chemically or physically adsorb with certain components in the lubricating oil, forming a thin lubricating film.

l Chemical Reaction Film: Under heavy load, high temperature, or high-speed conditions, extreme pressure additives in the lubricating oil (such as sulfur, phosphorus, nitrogen, etc.) react chemically with the metal surface, generating a layer of inorganic film with a high melting point and low shear strength, effectively preventing adhesive wear on the metal surface.

l Physical Adsorption Film: Under light or medium load conditions, certain components in the lubricating oil form a lubricating film on the metal surface through physical adsorption. Although thin, this film still provides a certain degree of lubrication.

l Efficient Lubrication Performance: Boundary lubrication bearings can provide effective lubrication under low-speed, medium-load, or heavy-load conditions, significantly reducing the coefficient of friction and wear.

l Excellent Load-bearing Capacity: Boundary lubrication bearings have a high load-bearing capacity and can maintain stable operation under harsh working conditions.

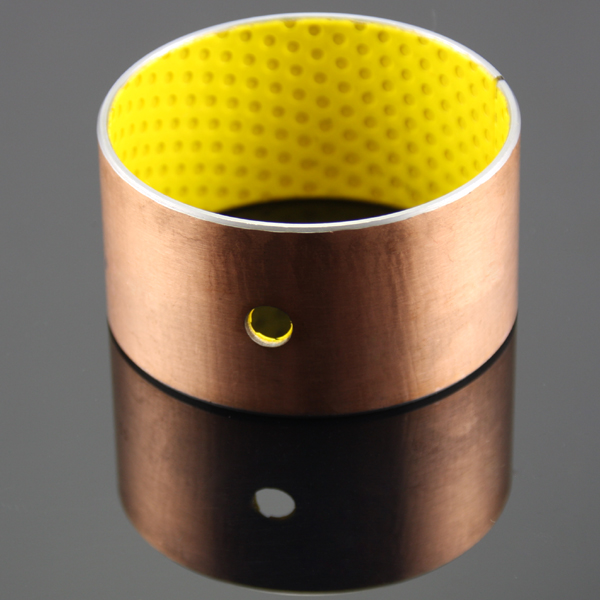

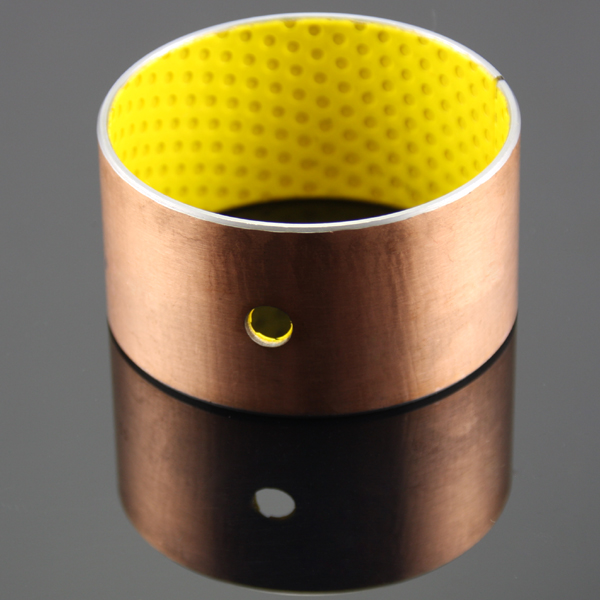

l Low Cost and Long Service Life: Boundary lubrication bearings are typically manufactured using special materials, such as a steel plate as the base, sintered spherical bronze powder in the middle, and surface-rolled modified polyoxymethylene (POM), resulting in a long service life and low maintenance costs.

II. Advantages of Boundary Lubrication Bearings

l Reducing Friction and Wear: Boundary lubrication bearings can effectively reduce the coefficient of friction and the amount of wear, extending the service life of equipment.

l Improving Transmission Efficiency: Good lubrication performance makes the transmission system smoother, improving the transmission efficiency of the equipment.

l Reducing Costs: Due to reduced consumption of lubricants and maintenance costs, boundary lubrication bearings have a lower total life cycle cost.

l Environmental Protection and Energy Saving: Boundary lubrication bearings reduce the use and emission of lubricants, contributing to reducing the impact on the environment.

III. Differences Between Boundary Lubrication Bearings and Self-lubricating Bearings

Different Lubrication Methods:

l Boundary lubrication bearings primarily rely on the lubricating film formed between external lubricating oil and the metal surface to achieve lubrication.

l Self-lubricating bearings typically achieve lubrication through the lubricating effect of their own materials (such as solid lubricants) without the need for external lubricating oil.

Different Application Scenarios:

l Boundary lubrication bearings are more suitable for situations where external lubricating oil is required and the working conditions are relatively harsh (such as heavy loads, high temperatures, high speeds).

l Self-lubricating bearings are more suitable for places where oil cannot be added or is difficult to add, such as some small mechanical equipment or spaces with limited access.

IV. Specific Application Scenarios of Boundary Lubrication Bearings

l Automotive Chassis: Boundary lubrication bearings play an important role in the automotive chassis system, such as in steering knuckle bearings and hub bearings, ensuring smooth and safe driving.

l Forging Press Machines: In forging press machines, boundary lubrication bearings can withstand large impact loads and frictional wear, ensuring stable operation of the machine.

l Metallurgical and Mining Machinery: Boundary lubrication bearings in metallurgical and mining machinery can maintain stable lubrication performance under high temperatures, heavy loads, and harsh environments, extending the service life of the equipment.

l Construction Machinery: Boundary lubrication bearings in construction machinery can withstand large loads and impacts, ensuring normal operation and work efficiency of the equipment.

l Hydropower and Steel Rolling Industries: In industries such as hydropower and steel rolling, boundary lubrication bearings also play an important role, ensuring stable operation and efficient transmission of the equipment.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. produces the FB090 boundary lubrication bushing, which is loved by customers for its unique material advantages and boundary lubrication performance. If you have purchasing needs, please feel free to contact us: [email protected].

English

English Español

Español

Contact Us