Thrust washers, like other types of washers, serve specific functions within mechanical systems to manage loads, reduce friction, and prevent wear. Here’s a breakdown of the key differences between thrust washers and other common types of washers:

Thrust Washers

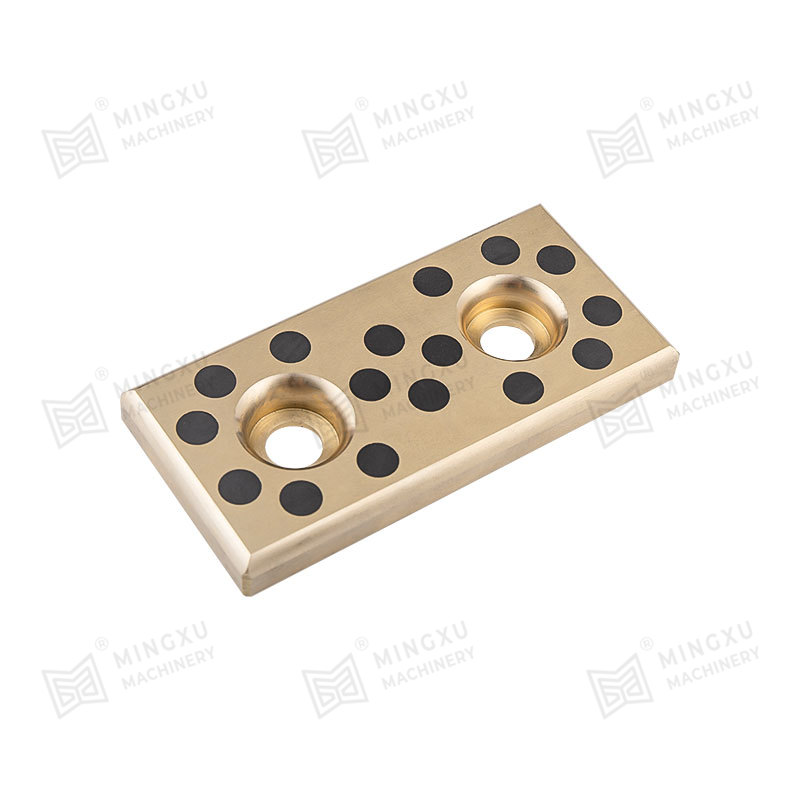

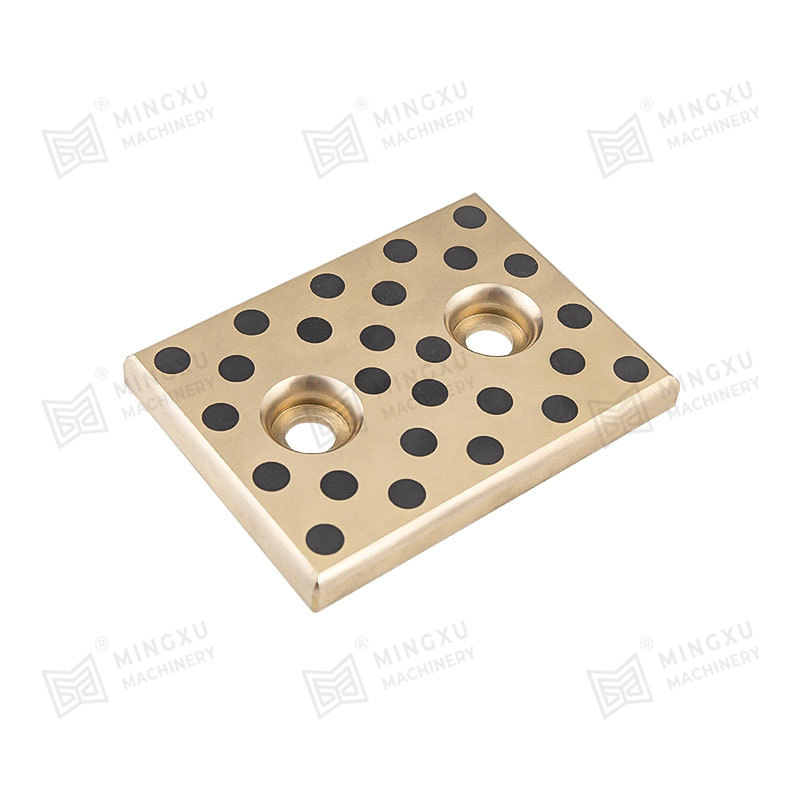

Function: Thrust washers are specifically designed to support axial loads (parallel to the axis of rotation) in rotating or sliding applications. They help distribute the load and reduce friction between moving parts.

Design:

Flat Surface: They typically have a flat surface to provide support against thrust loads.

Center Hole: Often have a center hole to fit around shafts or bolts, allowing them to rotate with the shaft or bolt.

Thin Profile: Usually thinner compared to other washers to minimize the space required in assemblies.

Materials: Common materials include bronze alloys, steel, stainless steel, polymers (such as nylon), and composite materials. These materials are chosen for their wear resistance, load-bearing capacity, and friction properties.

Applications: Used in various applications where axial loads need to be managed, such as automotive transmissions, industrial machinery, bearings, and thrust bearings.

Other Types of Washers (Comparison)

Flat Washers

Function: Used to distribute load, reduce friction, and prevent damage to surfaces under nuts, bolts, or screws.

Design: Typically have a flat circular shape with a hole in the center.

Materials: Commonly made from metal (steel, stainless steel, brass) or plastic (nylon).

Applications: Widely used in general fastening applications to distribute the load and protect surfaces from damage.

Lock Washers

Function: Prevent nuts and bolts from loosening under vibration or torque.

Design: Have teeth, ridges, or bends that grip the mating surface and the fastener to prevent rotation.

Materials: Typically made from metal (steel, stainless steel) to provide strength and durability.

Applications: Used in assemblies where securing fasteners against loosening due to vibration is critical, such as in machinery and automotive applications.

Spring Washers

Function: Provide a spring-like action to maintain tension and prevent loosening of fasteners under vibration.

Design: Usually have a split or wave-like shape that compresses when tightened, exerting a spring force.

Materials: Made from metal (steel, stainless steel) for strength and resilience.

Applications: Used in applications where maintaining tension and preventing loosening due to vibration are essential, such as automotive suspensions and industrial equipment.

Key Differences

Load Orientation: Thrust washers handle axial loads (parallel to the axis of rotation), whereas other washers like flat washers, lock washers, and spring washers primarily manage radial loads (perpendicular to the axis of rotation).

Design and Function: Thrust washers are specifically designed to withstand thrust forces and provide support in axial directions, whereas other washers serve different functions such as distributing loads, preventing loosening of fasteners, or providing spring tension.

Materials and Applications: The choice of materials and applications vary based on the specific requirements of the mechanical system. Thrust washers are chosen for their ability to handle thrust loads effectively, while other washers are selected based on their unique functions in fastening and assembly operations.

Understanding these differences helps in selecting the appropriate washer type for different mechanical applications, ensuring efficient and reliable performance of the assembled components.

English

English Español

Español

Contact Us