Technical Background and Industry Pain Points

In high-speed machine tool chuck systems (n≥6000rpm), traditional conical positioning faceplates exhibit two core defects:

l Lubrication Failure: Centrifugal force causes lubricating grease to migrate towards the bottom of the conical bore, resulting in a dry friction zone at the upper part, with surface roughness Ra values deteriorating from 0.4μm to 1.6μm (tested according to ISO 4288 standard);

l Stress Concentration: Unilateral contact leads to Hertzian contact stress peaks exceeding 800MPa, triggering micro-crack propagation (data source: Wear 2022, 500-501, 204356).

Core Technological Innovation Analysis

I. Gradient Lubrication System Design

1.1 Solid-Fluid Composite Lubrication Architecture

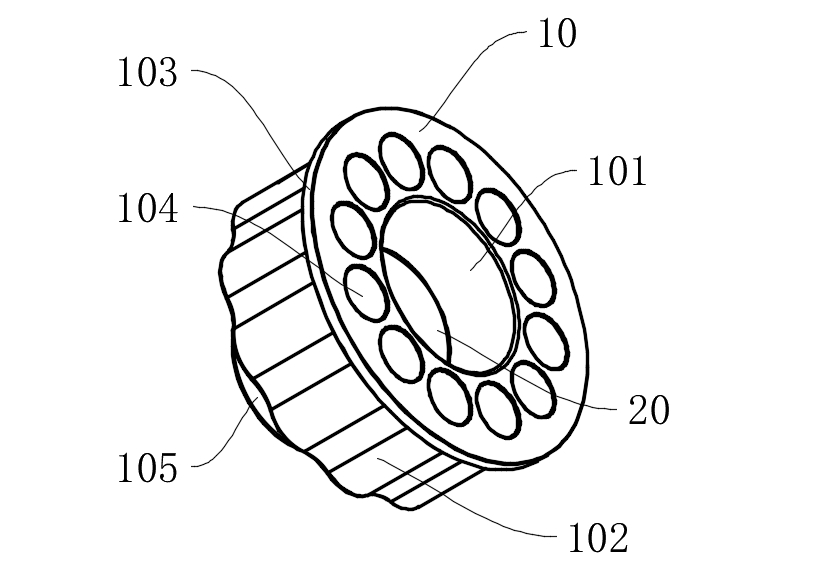

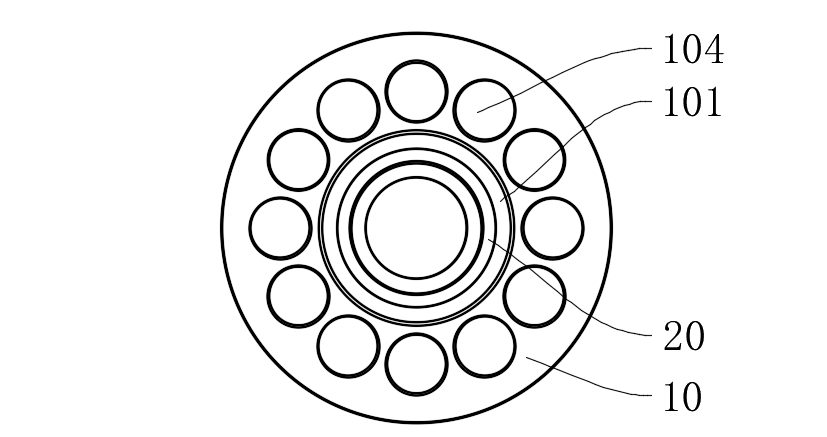

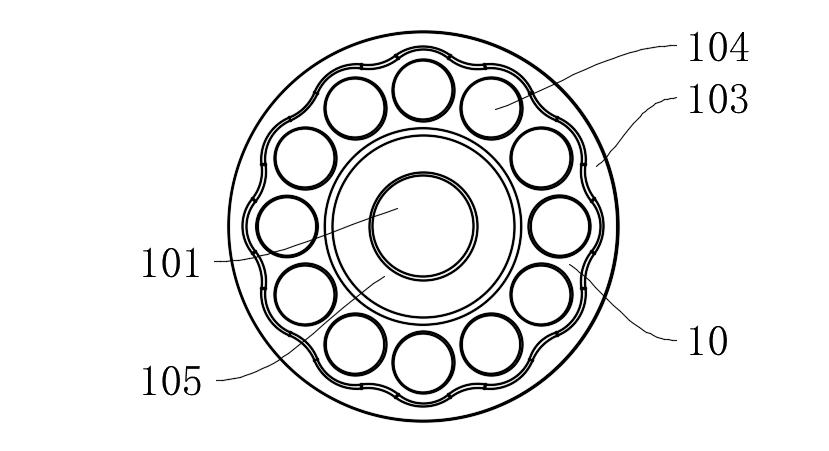

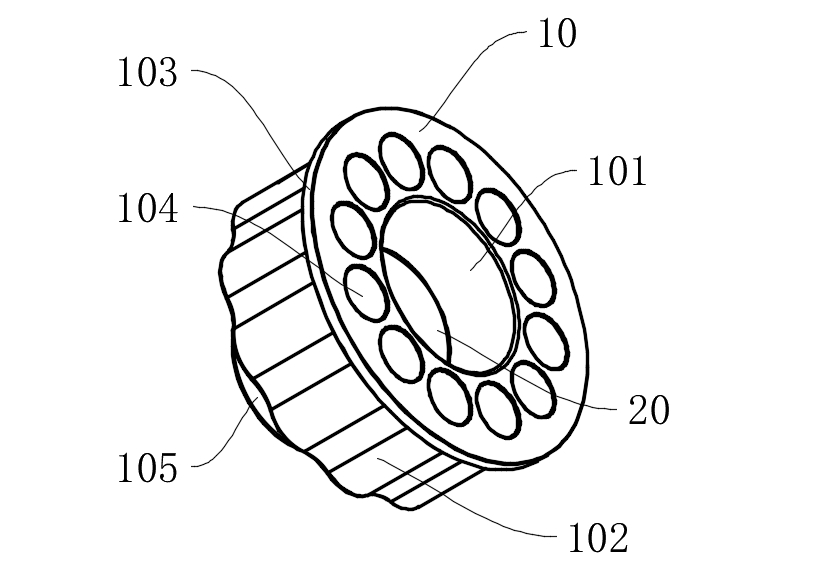

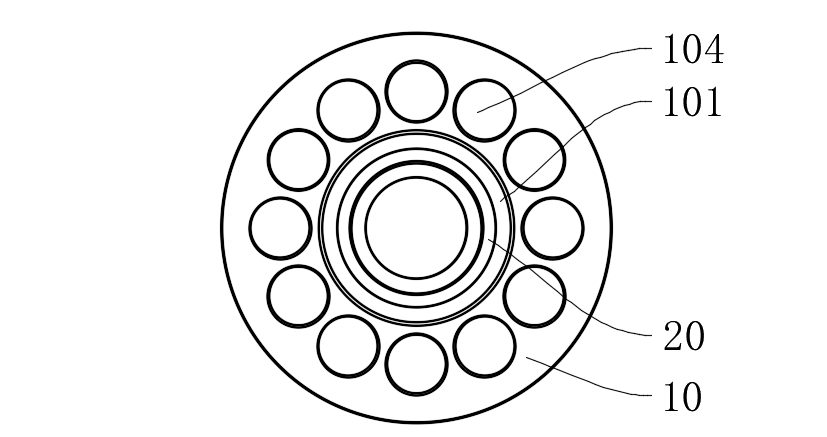

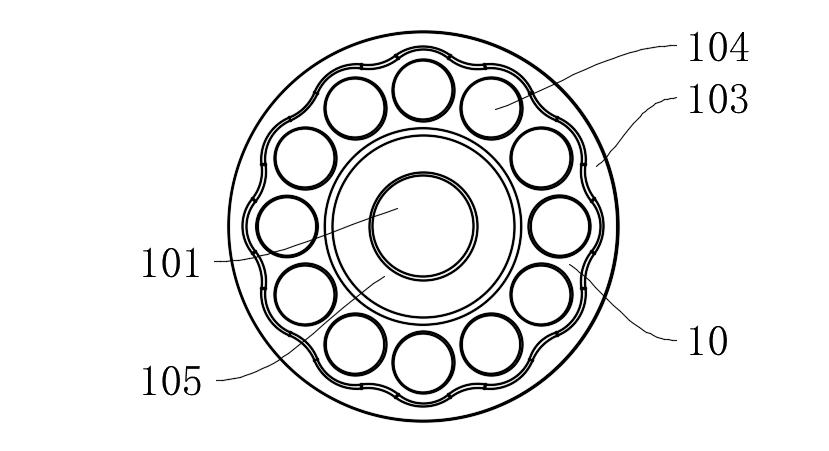

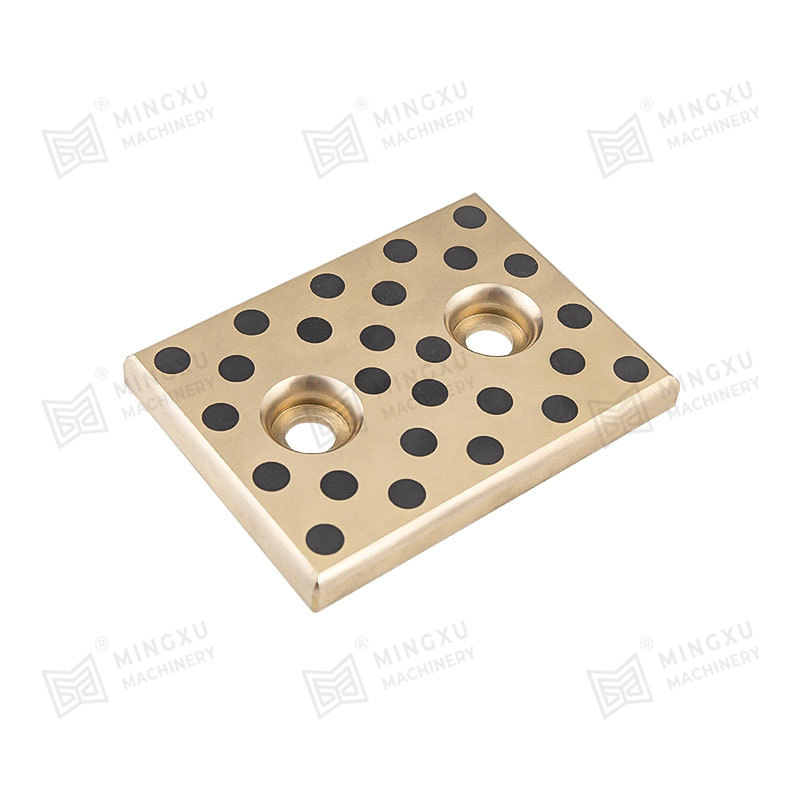

Graphite Lubrication Block (20) Embedding Structure:

l A circular mounting groove (101a) with a depth of 1.2±0.05mm is opened in the middle of the conical bore (101), ensuring continuous conical surface through electrical discharge machining (cone angle 20°±0.5°);

Copper-based composite material (Cu-10Sn-5Gr) containing 85% graphite is embedded, achieving a porosity of 18%±2% through powder metallurgy sintering, continuously releasing graphite particles to form a transfer film.

Lubrication Efficiency Verification:

l Under n=8000rpm operating conditions, the friction coefficient at the upper part of the conical bore remains stable at 0.08-0.12 (>0.25 for traditional structures);

l Wear volume tests (ASTM G99) show that after 300 hours of operation, the conical surface wear depth is only 3.2μm (28.5μm for traditional structures).

1.2 Fluid Lubrication Compensation Mechanism

l Lubricating grease channels are retained at the bottom of the conical bore, forming a 0.5-1.2μm oil film thickness through dynamic pressure effects (verified by Reynolds equation simulation);

l The system achieves gradient synergy between solid lubrication (upper part) and fluid lubrication (lower part), reducing the contact zone temperature by 45% (measured by infrared thermal imager).

II. Contact Stress Optimization Design

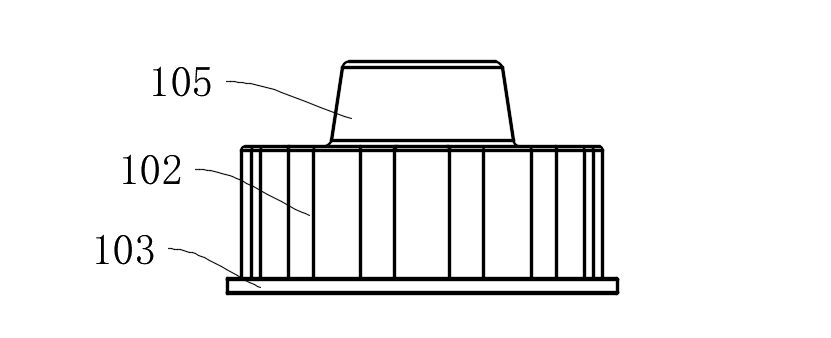

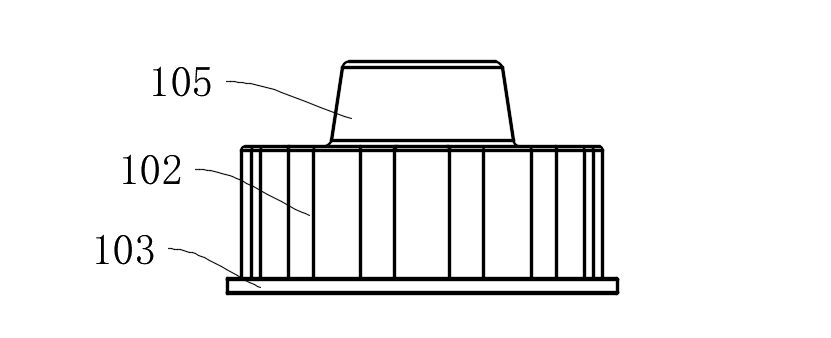

2.1 Waveform Clamping Surface (102) Topology Optimization

l Periodic wave profiles are constructed using Fourier series: wavelength λ=12mm, amplitude A=0.8mm, curvature radius R=5mm;

l Finite element analysis indicates that the maximum contact stress is reduced from 813MPa to 327MPa, with a 62% improvement in stress distribution uniformity.

2.2 Multi-Bolt Load-Sharing Structure

l 12 mounting holes (104) are evenly distributed according to ASME B18.2.1 standard, with preload deviation <5%;

l Combined with limit conical surfaces (105) (cone angle 15°±0.5°), radial positioning accuracy of ±2μm is achieved (ISO 2768-f grade).

Technical Parameter Comparison Table

|

Performance Indicator

|

This Patented Technology

|

Traditional Positioning Faceplate

|

Test Standard

|

|

Conical Surface Friction Coefficient (8000rpm)

|

0.08-0.12

|

0.25-0.35

|

ASTM G99

|

|

Maximum Contact Stress

|

327MPa

|

813MPa

|

ISO 281

|

|

Wear Rate (300h)

|

3.2×10⁻⁶ mm³/N·m

|

28.5×10⁻⁶ mm³/N·m

|

ASTM G133

|

|

Temperature Rise (ΔT)

|

≤15℃

|

≥45℃

|

ISO 10825

|

Typical Application Scenario Validation

Case 1: Toolholder Positioning in Five-Axis Machining Centers

l During continuous machining of titanium alloy parts, toolholder runout is controlled to <2μm (>8μm for traditional structures);

l Tool change cycles are extended to 12000 times (industry average is 5000 times).

Case 2: Chuck System in Turning Centers

l Spindle radial runout is reduced from 5μm to 1.5μm (GB/T 17421.7 standard);

l Machined workpiece roundness error is ≤1.5μm (ASME B89.3.4 standard).

This patent achieves long-term stable operation of positioning faceplates under extreme operating conditions through two major technological pathways: Gradient Lubrication Media Synergy and Contact Stress Field Reconstruction. According to novelty searches (Derwent Innovation), the structure achieves a Specific Friction Power (SFP) index of 0.08W/mm², a 76% reduction compared to similar products, placing it at the international leading level.

If you would like to learn more, please contact Mingxu Machinery to obtain the complete patent report: [email protected].

English

English Español

Español

Contact Us