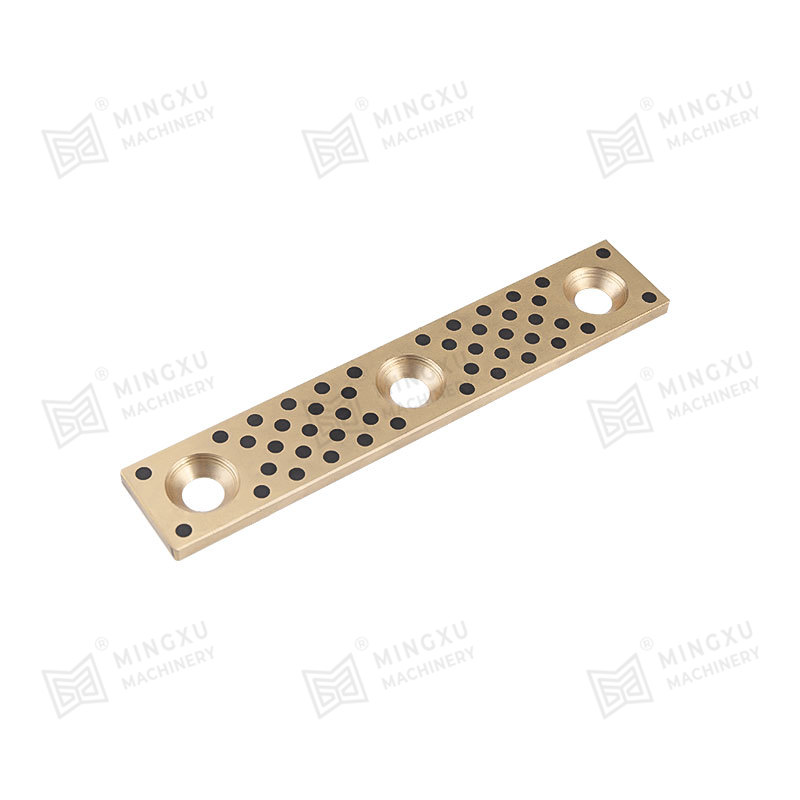

MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See DetailsContent

Maintenance-free bearings reduce downtime and eliminate routine lubrication, but they are not universally suitable for every application. Selecting an appropriate maintenance-free bearing requires matching bearing design, materials, and protective features to load profiles, speed, environment, and expected service life. This article walks through concrete, technical factors to evaluate and provides practical checks to ensure the chosen bearing performs reliably for the equipment’s lifecycle.

Determine the maximum static and dynamic radial and axial loads the bearing will carry. Maintenance-free bearings come in various constructions—deep groove, angular contact, cylindrical roller, or plain self-lubricating bearings—each optimized for particular load directions and magnitudes. Select a bearing whose dynamic load rating (Cr or equivalent) and static load rating (C0r) exceed the expected forces with an appropriate safety margin for shock or transient overloads.

Use real operating data or mechanical analysis to estimate peak loads. Include consequences of misalignment, start-stop torque spikes, and any known impact events. Where load is variable, consider the bearing’s fatigue life curves to estimate L10 life under the expected load spectrum.

Match the bearing’s permissible rotational speed to the equipment’s operating RPM. Even “maintenance-free” bearings generate heat from internal friction; high continuous speeds increase internal temperatures and accelerate lubricant depletion in sealed designs or deterioration of self-lubricating polymers. Confirm the bearing’s maximum steady-state and limiting speeds, and evaluate whether additional cooling or lower-viscosity lubricants (if applicable) are required.

Estimate steady-state operating temperature considering ambient conditions and heat sources. If operating temperatures exceed recommended limits for the bearing’s materials or lubricant system, select high-temperature grades or designs with heat-dissipating features.

Assess particulate contamination, moisture exposure, chemicals, and salt spray. Maintenance-free bearings often rely on seals, shields, or self-lubricating liners to block contaminants. In dusty, wet, or corrosive environments, choose bearings with robust sealing, corrosion-resistant steels, or alternative materials such as stainless steel, coated metals, or polymer composites designed for the environment.

Maintenance-free bearings use diverse materials: precision steels with sealed grease, bronze or brass with embedded solid lubricants, PTFE-lined plain bearings, and advanced composites with self-lubricating fillers. Material choice impacts load capacity, wear resistance, temperature range, chemical compatibility, and electrical conductivity. Choose a material system that balances mechanical demands with environmental compatibility and life expectancy.

Use polymer or composite bearings where low friction, dry-running capability, corrosion resistance, and the ability to tolerate marginal lubrication are prioritized over high-speed rolling element performance. These are common in food equipment, packaging machinery, and outdoor fixtures.

Understand dominant wear modes in your application—abrasive, adhesive, fatigue, or corrosive wear—and choose a maintenance-free bearing engineered to resist those modes. Manufacturers provide L10 or equivalent life estimates; translate these into calendar life under actual load and speed to check whether the bearing meets lifecycle targets. For critical equipment, consider scheduled inspections even for maintenance-free designs to verify performance.

Correct fit is essential: interference or clearance fits, shaft finish, and housing tolerances affect preload, heat transfer, and service life. Maintenance-free bearings may include press-fit housings, flanges, or cartridges—confirm mounting recommendations and tolerances with the supplier. Improper installation is a common cause of premature failure even with maintenance-free systems.

Use recommended mounting tools, control installation temperature when press-fitting, and ensure shaft straightness and surface finish. For plain self-lubricating bearings, follow break-in procedures if specified.

Request manufacturer data sheets with dynamic and static load ratings, speed limits, permissible temperature range, material composition, and testing standards. Look for bearings tested to recognized standards (ISO, ASTM, DIN) and ask for test certificates for critical or high-volume orders. Verify warranty terms and failure modes covered by the supplier.

While maintenance-free bearings can reduce labor and lubrication costs, initial price and replacement intervals affect total cost of ownership. Compare the installed cost plus predicted replacement frequency to an equivalent maintainable bearing with scheduled relubrication. Factor in downtime costs, access difficulty (bearings in hard-to-reach locations justify maintenance-free premium), and environmental or contamination control savings.

| Cost Factor | What to include | Impact on decision |

| Initial bearing cost | Unit price, shipping, spares | Budget constraint vs performance |

| Maintenance savings | Lubrication labor, lubricant cost | Reduces recurring OPEX |

| Downtime risk | Replacement time, access difficulty | High for inaccessible bearings—favours maintenance-free |

When possible, run a field trial or prototype test under realistic loads and environment to validate predicted life. Measure temperature rise, vibration, and wear after defined hours of operation. For mission-critical systems, include accelerated life testing or supplier-run endurance data to confirm the bearing meets lifecycle objectives.

Use the checklist below before final procurement to ensure all critical factors are addressed.

Maintenance-free bearings offer real advantages but must be selected with technical rigor. Evaluate loads, speeds, environment, materials, thermal behavior, and mounting precisely. Validate supplier claims with data sheets and, where feasible, field testing. When chosen and installed correctly, maintenance-free bearings reduce lifecycle costs and simplify operations—when chosen poorly, they can fail prematurely and increase total cost. Prioritize specification alignment to ensure reliable, long-term performance.

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JGLDW self-lubricating guide rails are made of high-strength brass through CNC machine tools. The surface is inlaid with solid lubricants such as ...

See Details

MGB61 NAAMS Standard Guide Bushing is a reliable solution for precise, smooth guide applications. This guide bushing is designed to meet NAAMS standar...

See Details

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MSEW JIS 20mm Standard Wear Plate is based on high-strength brass, tin bronze, steel-copper bimetal, cast iron or bearing steel. The surface is inlaid...

See Details

MJGBF oil-free injection guide bushings are components used in the plastic injection molding process to further improve manufacturing efficiency by en...

See Details

Normally, the push plate is supported by four reset rods. However, due to the low installation accuracy of the reset rods, when the push plate is larg...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us