Automobile Solid Lubricant Bushings are critical components in modern vehicles, designed to reduce friction and wear in moving parts without the need for external lubrication. These bushings are widely used in suspension systems, steering mechanisms, and engine components where traditional lubricants may be impractical or maintenance-intensive.

Choosing the right automobile Solid Lubricant Bushing requires a clear understanding of the materials used, performance characteristics, and application requirements. This guide explores the key factors to consider when selecting bushings for automotive applications.

Key Materials Used in Automobile Solid Lubricant Bushings

Automobile Solid Lubricant Bushings are manufactured from a variety of materials, each providing unique performance benefits:

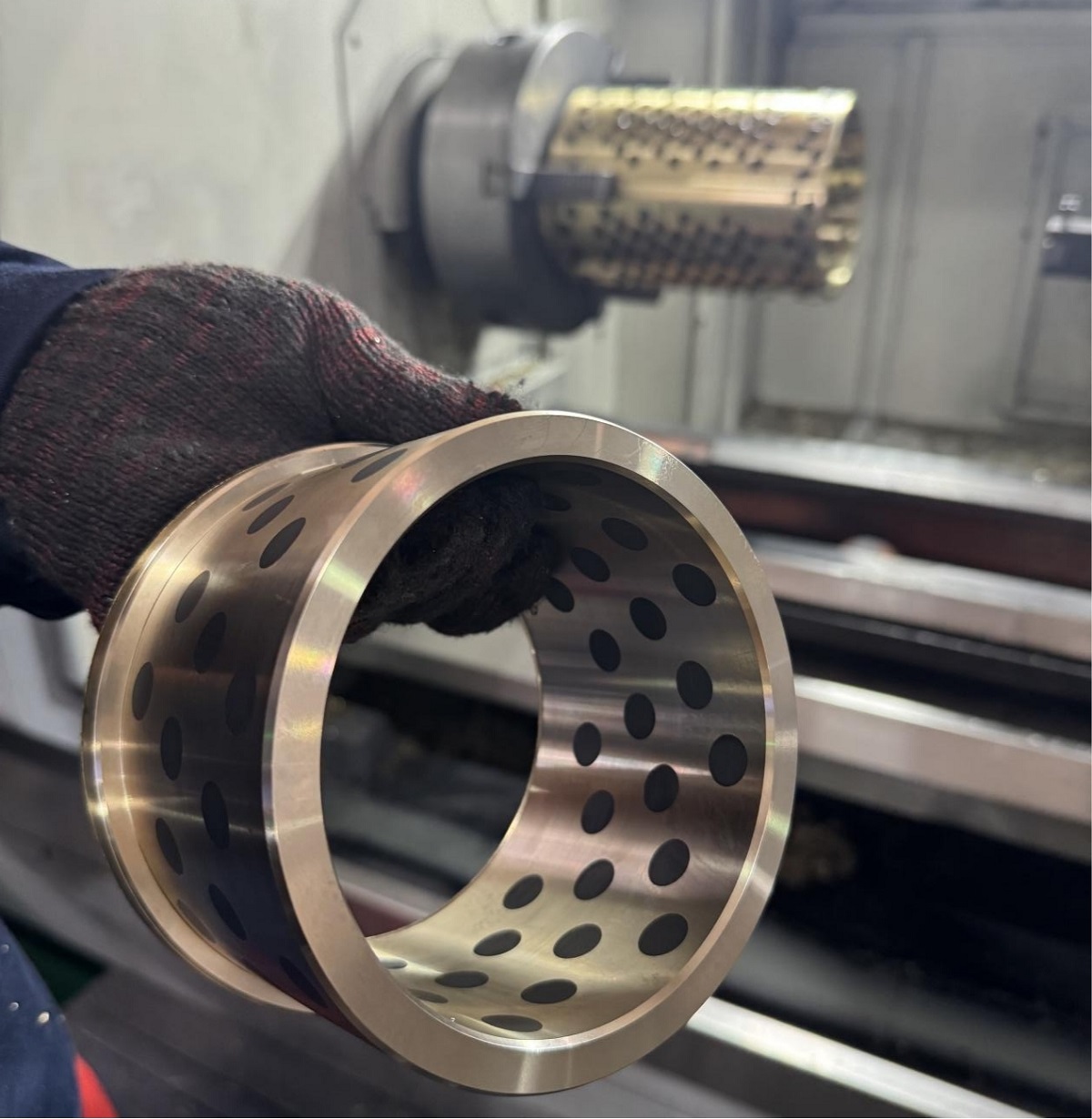

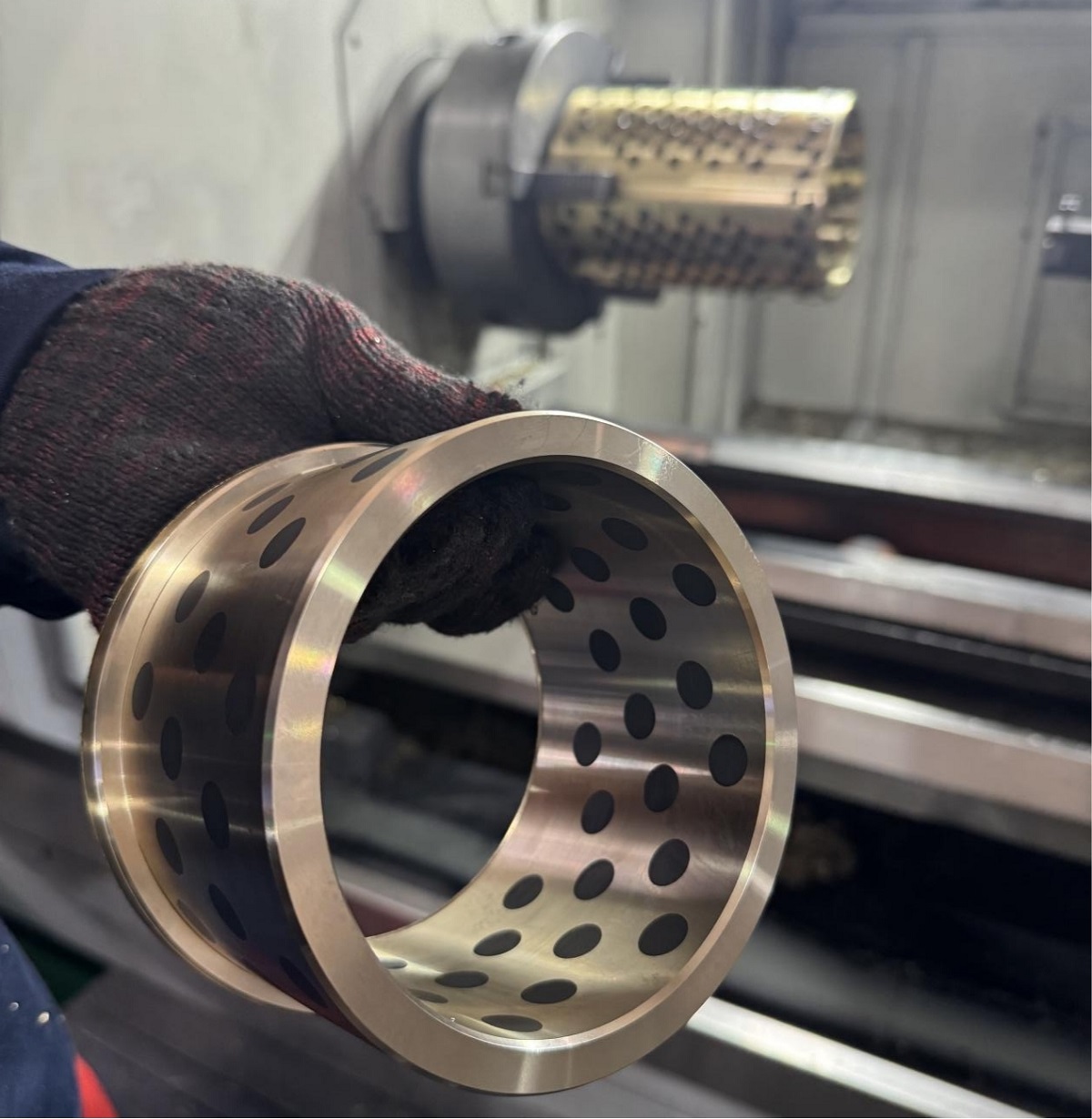

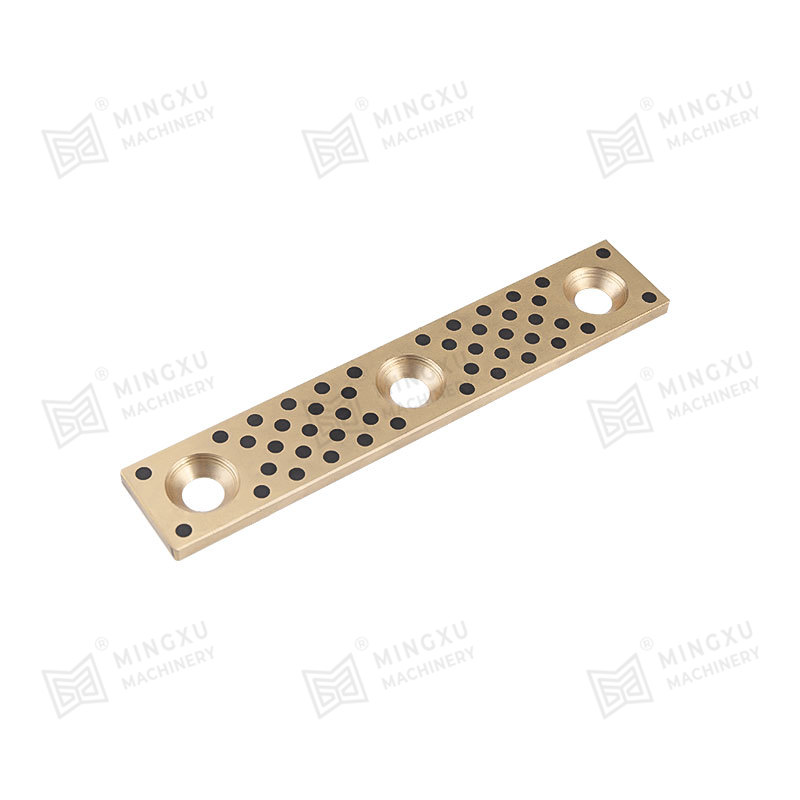

- Bronze with Solid Lubricant Coating: Offers excellent wear resistance and load-bearing capability, ideal for high-stress suspension and steering applications.

- PTFE-Embedded Composites: Provide low friction and smooth motion, reducing noise and improving efficiency in moving automotive parts.

- Sintered Metal Alloys: Suitable for high-temperature environments, maintaining durability and lubrication even under extreme engine conditions.

- Polymer-Based Bushings: Lightweight and resistant to corrosion, often used in applications where reduced weight is important without compromising performance.

Performance Considerations

When selecting an automobile Solid Lubricant Bushing, performance characteristics are just as important as material choice. Key performance factors include:

Load Capacity

The bushing must withstand the weight and dynamic loads of the vehicle components it supports. Bronze and sintered metal bushings typically provide higher load capacities compared to polymer-based bushings.

Friction and Wear Resistance

Low friction is essential for smooth operation and reduced wear. PTFE-embedded composites and solid lubricant coatings minimize contact friction, prolonging bushing life and enhancing overall vehicle performance.

Temperature Tolerance

Automobile Solid Lubricant Bushings in engine or exhaust-adjacent locations must resist high temperatures without degrading. Sintered metals and high-performance polymers are suitable for such conditions.

Noise and Vibration Dampening

Polymer-based and composite bushings often excel at reducing noise and vibration, improving passenger comfort and vehicle refinement.

Applications in Automotive Systems

Automobile Solid Lubricant Bushings are used in multiple areas of a vehicle:

| Vehicle Component |

Bushing Material |

Function |

| Suspension Arms |

Bronze with Solid Lubricant |

Reduces friction, supports heavy loads |

| Steering Linkages |

PTFE-Embedded Composites |

Smooth movement and precise control |

| Engine Mount Points |

Sintered Metal Alloys |

High-temperature tolerance and durability |

| Door Hinges and Panels |

Polymer-Based Bushings |

Noise and vibration reduction, lightweight |

Selecting the Right Automobile Solid Lubricant Bushing

To choose the best bushing, consider the following steps:

- Identify the application and load requirements of your vehicle component.

- Evaluate material properties such as wear resistance, friction coefficient, and temperature tolerance.

- Consider maintenance-free operation and long-term durability.

- Balance performance needs with cost constraints.

- Verify compatibility with existing vehicle systems and installation requirements.

Conclusion

Automobile Solid Lubricant Bushings provide reliable, maintenance-free performance in a wide range of vehicle applications. By carefully considering material selection, performance characteristics, and system requirements, automotive engineers and enthusiasts can ensure optimal efficiency, durability, and comfort.

Selecting the right bushing improves vehicle longevity, reduces maintenance costs, and enhances overall performance. Understanding both materials and performance factors is key to choosing the best automobile Solid Lubricant Bushing for your car.

English

English Español

Español

Contact Us