In the realm of high-end industrial equipment, material technology has emerged as a core driving force for enhancing equipment performance and extending service life. Whether it's high-speed trains hurtling along tracks or desalination plants operating around the clock, innovative materials quietly safeguard the efficient and stable functioning of these systems. Self-lubricating copper alloy bearings and anti-biofouling aluminum brass stand out as exemplary representatives, leveraging technological advancements to address industry pain points and embodying the modern industrial philosophy of "materials lead the way, reliability is fundamental."

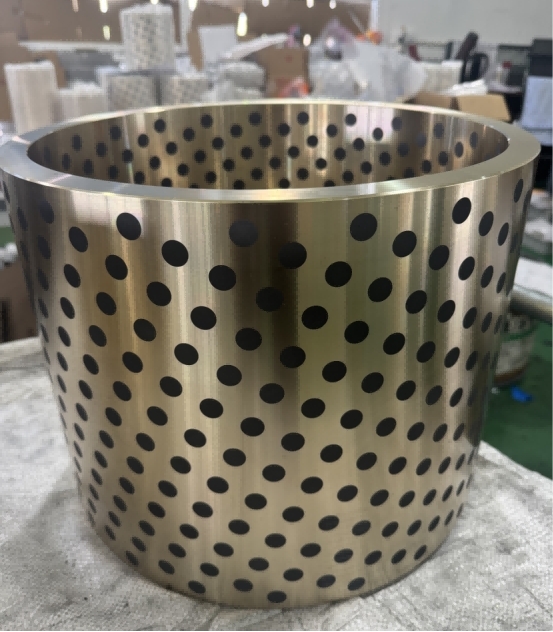

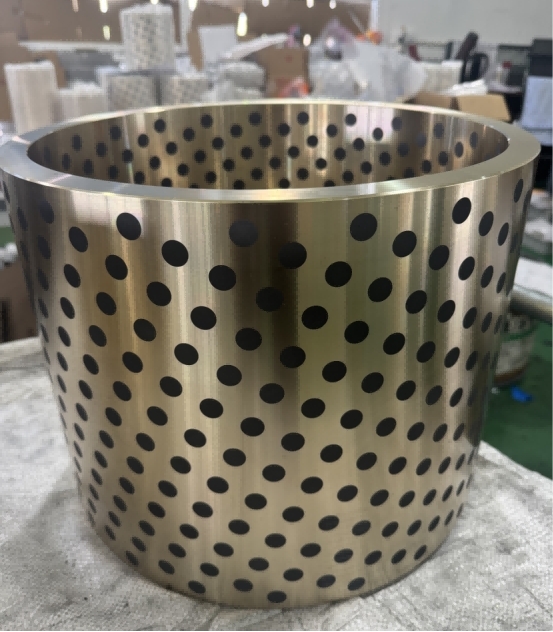

Self-Lubricating Bearings: The "Joint" Technology Ensuring Stable and Long-Distance Travel for High-Speed Trains

High-speed train bearings face severe wear challenges under extreme operating conditions. Self-lubricating copper alloy materials, incorporating solid lubricants such as graphite and molybdenum disulfide, continuously form a lubricating film during operation, significantly reducing friction coefficients and achieving an impressive 50,000-hour wear resistance. By eliminating reliance on external lubrication, these bearings substantially reduce maintenance frequency, enhancing both operational economy and safety. They have become a crucial choice for key components in rail transportation.

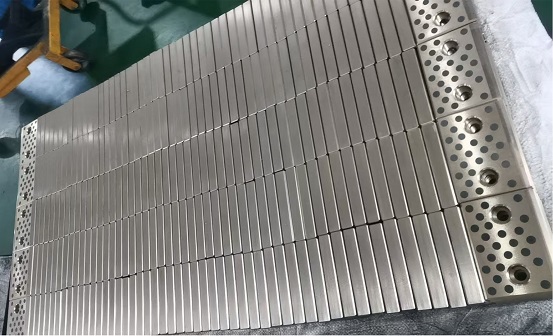

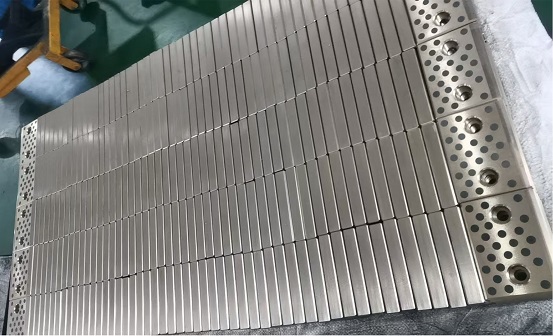

Anti-Biofouling Aluminum Brass Technology: A "Protective Barrier" for Desalination Systems

During the desalination process, biofouling poses a primary threat to equipment efficiency and lifespan. Aluminum brass employs a triple mechanism—copper ion slow-release sterilization, surface microstructure anti-adhesion, and electrochemical inhibition—to effectively prevent the accumulation of microorganisms, algae, and other substances on pipeline, filter, and heat exchanger surfaces. Practical applications demonstrate that systems utilizing aluminum brass components can extend maintenance intervals to 1-2 years and double membrane lifespan, significantly reducing freshwater production costs.

Collaborative Innovation: Cross-Disciplinary Empowerment of Major Equipment through Material Technology

Although self-lubricating and anti-biofouling technologies serve different application scenarios, they collectively highlight the collaborative intelligence inherent in material design:

Both utilize copper-based materials as platforms, achieving functional self-sufficiency through multi-alloying and structural optimization.

Both possess long-lasting self-maintenance characteristics, reducing dependence on external systems and manual intervention.

Both excel in extreme environments, adapting to complex operating conditions involving high loads, high corrosion, and multiple media.

Future Prospects: Material Intelligence and System Integration

With the widespread adoption of new technologies such as smart manufacturing and the Internet of Things, self-lubricating bearings are evolving towards embedded sensing and wear self-monitoring capabilities. Aluminum brass materials are also focusing on developing adaptive ion release and surface reconstruction abilities. Their integrated applications in high-end equipment, new energy, and environmental engineering sectors are accelerating, promising to create a smarter, more efficient, and reliable industrial equipment material system in the future.

Materials form the cornerstone of industry, while innovation serves as the engine of progress. From high-speed trains to vast oceans, self-lubricating copper alloy and aluminum brass materials demonstrate the practical significance of technology in safeguarding operations through their exceptional performance. They also provide solid support for the upgrading and development of numerous industries.

English

English Español

Español

Contact Us