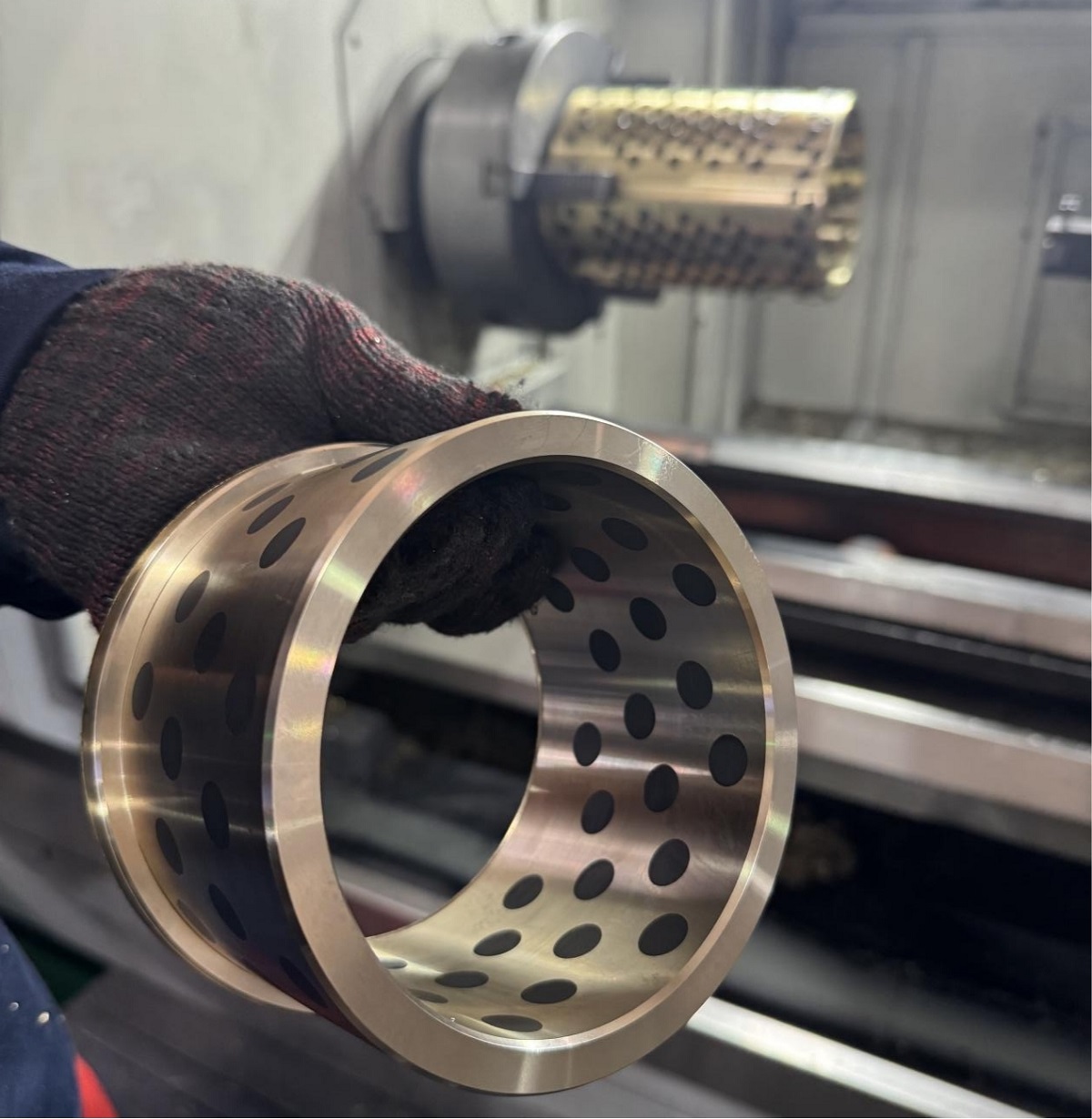

MXB-JFFB Self-Lubricating Half Bearing

Cat:Self-Lubricating Bearing

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See DetailsIn modern transportation systems, high-speed trains have become a vital choice for the public due to their efficiency and convenience. One of the core components ensuring the smooth and safe operation of trains is the bearing, which supports and enables wheel rotation. Given the high speeds, heavy loads, and complex external environments, the wear resistance of bearings directly impacts train safety and operational efficiency. In recent years, the application of copper alloy self-lubricating materials has brought revolutionary advancements to this field, successfully extending bearing wear resistance to 50,000 hours and significantly enhancing the reliability and cost-effectiveness of high-speed trains.

1. Extreme Operating Conditions for High-Speed Train Bearings

High-speed trains operate at remarkable speeds. For instance, China's "Fuxing" train can reach a maximum operational speed of 350 km/h. At such speeds, bearing rotational speeds increase sharply. For example, when the CRH3 train operates at 300 km/h, its bearing speed reaches approximately 1,730 r/min. High-speed rotation generates substantial centrifugal forces and friction, posing severe challenges to material strength and wear resistance. Additionally, frequent starts and stops subject bearings to continuous impact loads, while environmental factors such as humidity, dust, and temperature variations further exacerbate wear. Traditional bearing materials often require frequent maintenance and replacement, increasing operational costs and disrupting scheduling.

2. Composition and Structural Features of Copper Alloy Self-Lubricating Materials

Copper alloy self-lubricating materials are composed of a copper matrix reinforced with alloying elements like tin (Sn) and aluminum (Al), along with solid lubricants such as graphite and molybdenum disulfide (MoS₂). Tin enhances alloy strength and corrosion resistance, while aluminum aids in forming a dense oxide film to improve surface performance. Elements like lead also effectively optimize tribological properties.

The key to self-lubrication lies in the solid lubricants. Graphite's layered structure facilitates easy sliding during friction, while molybdenum disulfide's ultra-low friction coefficient (0.03–0.06) forms an effective lubricating film on contact surfaces, significantly reducing wear. These components work synergistically to create a material system that combines mechanical properties with self-lubricating functionality.

3. Key Mechanisms for Achieving 50,000-Hour Ultra-Long Wear Resistance

The self-lubricating mechanism operates as follows: during bearing operation, solid lubricants within the material gradually migrate to the friction surface, forming a continuous lubricating film that isolates direct metal-to-metal contact. This provides protection even during startup when lubrication may be insufficient, preventing early-stage wear.

Wear resistance is reinforced through solid solution strengthening and second-phase strengthening by alloying elements. For example, tin forms Cu₆Sn₅ strengthening phases, while aluminum generates Al₂O₃ dispersed particles, both enhancing material hardness and wear resistance. Surface oxide films also protect against environmental degradation.

Critically, a multi-scale synergy exists among the matrix, alloying elements, and lubricants: the matrix provides mechanical support, alloy phases enhance wear resistance, and lubricants continuously replenish the lubricating film, ensuring stable long-term performance under high-speed, heavy-load, and variable operating conditions.

4. Practical Application and Performance Validation

In actual operation on a high-speed rail line, bearings made of copper alloy self-lubricating materials demonstrated exceptional performance. After 50,000 hours of operation, their wear depth measured only 0.1–0.2 mm, significantly lower than the 0.5–1 mm wear observed in traditional materials. This extended maintenance intervals, reduced operational costs, improved ride smoothness, minimized vibration and noise, and enhanced the overall passenger experience.

5. Significant Advantages Over Traditional Materials

Compared to conventional bearing steels, copper alloy self-lubricating materials offer several advantages:

Self-lubrication: They eliminate reliance on external lubrication systems, preventing failures caused by lubrication loss.

Superior wear resistance: They excel in high-speed, high-load, and complex environments.

Enhanced corrosion resistance: They withstand harsh, humid, and dusty conditions effectively.

These characteristics make them ideal for long-term, high-reliability applications.

6. Technological Prospects and Future Directions

As high-speed rail technology continues to evolve, demand for higher-performing bearings will grow. Copper alloy self-lubricating materials are poised to achieve further breakthroughs through composition optimization (e.g., adding rare earth elements) and process innovation (e.g., powder metallurgy and surface coating technologies). Additionally, developing smart materials with self-sensing and self-adjusting capabilities represents a promising research avenue, providing critical support for the safety, efficiency, and intelligence of next-generation high-speed trains.

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See Details

FB090 bronze bearings are made of tin bronze alloy CuSn8. The surface can be rolled with diamond or hemispherical oil holes and oil grooves according ...

See Details

Mining machinery and equipment are very easy to wear during use. In order to extend the service life of the equipment, Mingxu Machinery recommends tha...

See Details

MXB-JTGLW self-lubricating guide rails provide resistance and reduce friction, ensuring extended durability and enhanced performance. This product pro...

See Details

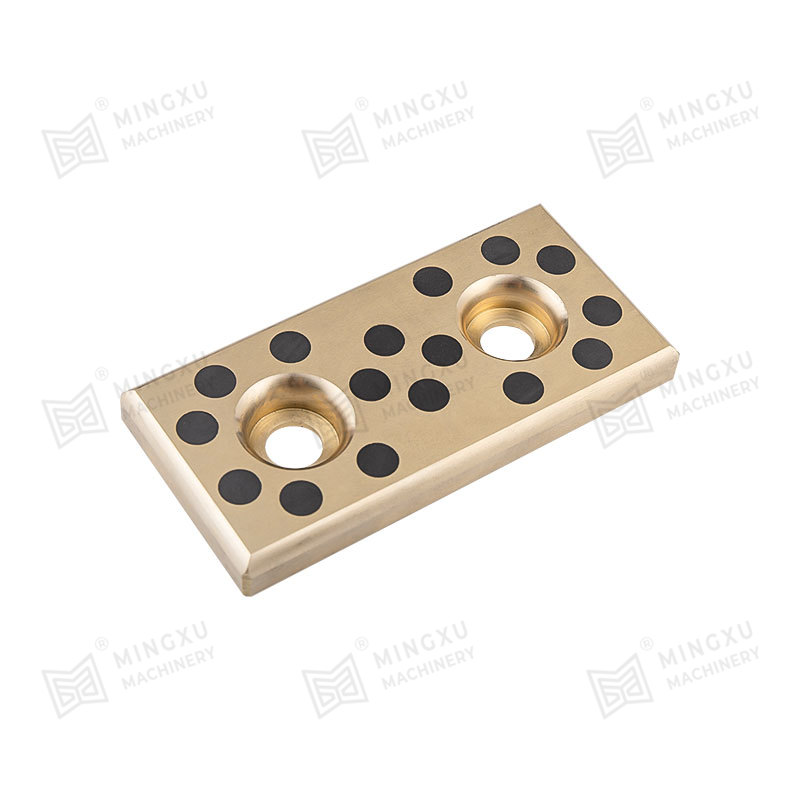

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MJGBF oil-free injection guide bushings are components used in the plastic injection molding process to further improve manufacturing efficiency by en...

See Details

Normally, the push plate is supported by four reset rods. However, due to the low installation accuracy of the reset rods, when the push plate is larg...

See Details

SF-1D hydraulic bearing is a new type of material designed based on SF-1P and combining the working principle of oil cylinder and shock absorber. It i...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

See Details

Contact Us