High-strength brass (mainly ZCuZn25Al6Fe3Mn3 or similar grades, also known as "high-strength brass" or "aluminum brass") has become the mainstream base material for graphite copper sleeves due to its optimal balance of strength, hardness, wear resistance, corrosion resistance, cost-effectiveness, and versatility. Here's a detailed analysis of the reasons:

1. High Strength and Hardness (Key to Load-Bearing Capacity)

Strengthening Mechanisms:

- Aluminum (Al): Forms hard β-phase (CuZnAl intermetallic compound), significantly enhancing the matrix's strength and hardness.

- Iron (Fe): Forms fine iron-rich particles that pin grain boundaries, refine grains, and impede dislocation movement, thereby improving strength, hardness, and wear resistance.

- Manganese (Mn): Enhances solid solution strengthening and improves hot working performance.

- Effects:

High-strength brass boasts a compressive strength (usually > 600 MPa) and Brinell hardness (HB > 150) that are significantly higher than those of ordinary brass (e.g., H62) and some lead bronzes.

This enables it to withstand higher loads and prevent excessive graphite column protrusion or failure under high PV (pressure × velocity) conditions due to matrix deformation.

2. Excellent Wear Resistance (Synergistic with Graphite)

Matrix Wear Resistance: The hard iron-rich phase and β-phase provide excellent resistance to abrasive and adhesive wear, protecting the matrix from scratches or plowing.

Graphite's Role: Embedded graphite provides solid lubrication, reducing the friction coefficient and adhesive tendency.

Synergistic Effect: The hard matrix supports the graphite columns, preventing excessive collapse under pressure, while the graphite reduces wear on the matrix itself. This "hard-soft combination" is the core advantage of self-lubricating bearings, and the hard matrix of high-strength brass is crucial to this design's success.

3. Good Corrosion Resistance (Ensuring Versatility)

Aluminum's Role: Forms a dense aluminum oxide (Al₂O₃) passivation film on the surface, significantly enhancing resistance to corrosion from atmospheric, seawater, weak acids, and weak bases.

Comparison: While its corrosion resistance is inferior to that of pure copper or tin bronze, it far exceeds that of ordinary brass (e.g., H62), making it suitable for most industrial environments (excluding strong acids and bases), automotive, construction machinery, and marine applications.

Cost-Effectiveness: Compared to expensive tin bronzes (e.g., ZCuSn5Pb5Zn5) or nickel-based alloys, high-strength brass offers lower costs while meeting corrosion resistance requirements.

4. Outstanding Cost-Effectiveness (Core Advantage)

Low Raw Material Costs:

Mainly composed of copper (Cu) and zinc (Zn), with zinc being significantly cheaper than alloying elements like tin (Sn), lead (Pb), and nickel (Ni).

Compared to tin bronzes (with 5-10% tin content) and lead bronzes (with high lead + tin costs), high-strength brass offers significantly lower unit costs.

Good Processability:

Suitable for powder metallurgy (the mainstream manufacturing process): Excellent powder flowability, compressibility, and sinterability facilitate easy molding and mass production.

Also suitable for casting and machining.

Comprehensive Performance Compliance: Meets the strength, wear resistance, and corrosion resistance requirements of most operating conditions at optimal costs.

5. Good Thermal Conductivity (Crucial for Heat Dissipation)

Copper-based alloys inherently possess excellent thermal conductivity (far superior to steel or iron-based bearings).

Timely heat dissipation from friction prevents localized overheating, which could lead to lubrication failure (graphite oxidation) or material softening, crucial for maintaining stable bearing operation.

6. Compatibility with Graphite and Process Adaptability

Thermal Expansion Matching: The difference in thermal expansion coefficients between high-strength brass and graphite is relatively controllable (compared to aluminum-based or iron-based materials), reducing interface stress and detachment risks during temperature fluctuations.

7. High Versatility (Covering Most Medium-to-Heavy Load Conditions)

High-strength brass-based graphite copper sleeves are suitable for a wide range of scenarios:

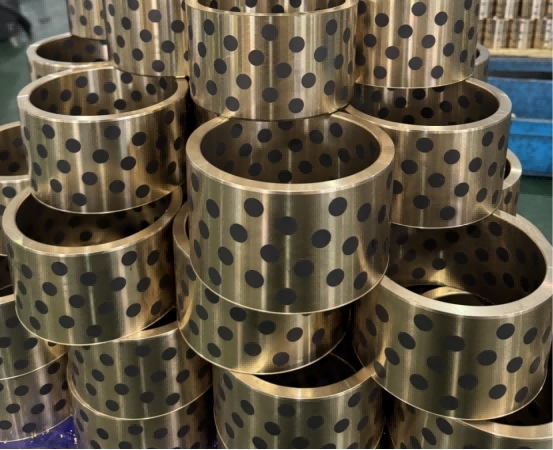

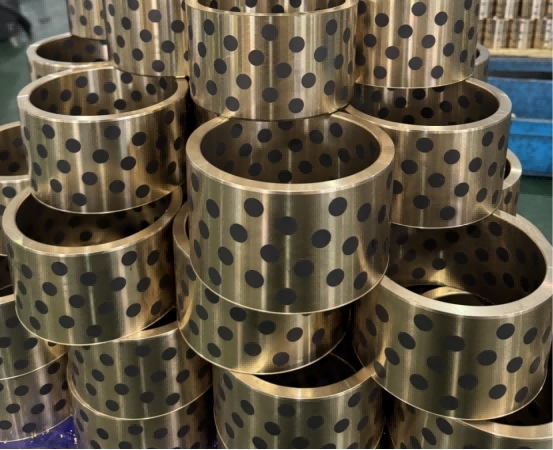

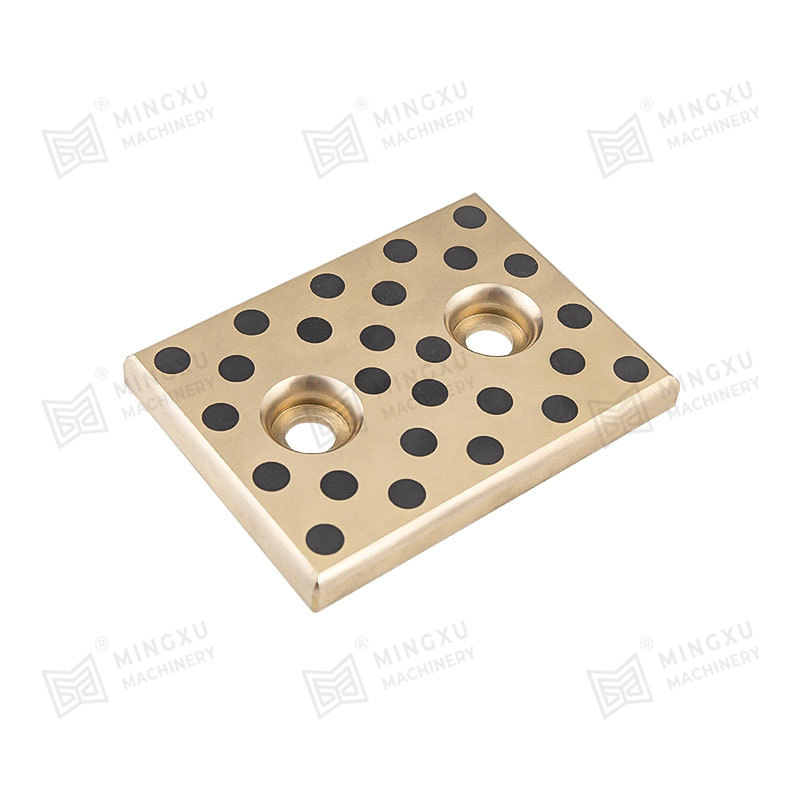

Medium-to-High Loads: Construction machinery (excavator arm pin bushings), agricultural machinery, metallurgical equipment, injection molding machines, etc.

Medium-to-Low Speeds: Conveyor rollers, hinges, steering mechanisms.

Corrosive Environments: Marine rudder systems, port machinery, water treatment equipment.

Maintenance-Free/Low-Oil Lubrication: Areas where frequent greasing is impractical (e.g., joints of aerial work platforms, bridge bearings).

Comparison with Other Copper-Based Materials

Tin Bronze (e.g., ZCuSn5Pb5Zn5):

Advantages: Better corrosion resistance and excellent wear resistance (especially with lead for good friction reduction).

Disadvantages: High cost (due to expensive tin), generally lower strength and hardness than high-strength brass (especially without iron-manganese strengthening). Used in more premium or corrosion-resistant applications.

Lead Bronze (e.g., ZCuPb10Sn10):

Advantages: Exceptional embeddability, conformability, and anti-seizure capability, suitable for extremely high loads and impacts.

Disadvantages: High cost, lead segregation, environmental restrictions, and lower strength and hardness. Used in heavy-duty engine crankshaft bearings, etc.

Ordinary Brass (e.g., H62):

Advantages: Lowest cost.

Disadvantages: Low strength and hardness, poor wear resistance, and average corrosion resistance, unable to meet medium-to-high load requirements.

Conclusion: The Fundamental Reason for High-Strength Brass's Popularity

High-strength brass achieves a near-perfect engineering balance among high strength, high hardness, good wear/corrosion resistance, excellent thermal conductivity, superior powder metallurgy processability, and significant cost advantages.

It provides the most cost-effective and reliable base material solution for self-lubricating bearings under medium-to-high loads, moderate speeds, and common corrosive environments, meeting the core demands for performance, lifespan, and cost in most industrial applications.

Therefore, unless extreme operating conditions (e.g., strong acids and bases, ultra-high temperatures, extremely high impact loads) necessitate more expensive special alloys, high-strength brass-based graphite copper sleeves, with their exceptional comprehensive performance and cost-effectiveness, dominate the market.

English

English Español

Español

Contact Us