MXB-DU Oilless Bearing SF-1 Bushing High-Temperature Resistance

Cat:Oilless Bearing

SF stands for three-layer composite, namely steel plate layer, copper powder layer and plastic layer. The steel plate layer plays the role of assembly...

See Details

Content

C95400 copper alloy is a widely used metallic material across numerous fields. It belongs to the copper alloy family, which consists of alloys with copper as the base matrix and one or more other elements added. The composition and properties of these alloys are carefully tailored to meet the demands of various industrial and application scenarios.

Classification and Composition of C95400 Copper Alloy by Function

Influence of Composition

The specific composition of C95400 copper alloy determines its crystallization characteristics and casting performance. The proportion of different elements plays a crucial role in the solidification process of the alloy. For example, the addition of certain elements affects the solidification temperature range, thereby influencing the casting process.

Casting Performance

Different crystallization characteristics and fluidity lead to varying degrees of shrinkage cavities and porosity. For instance, tin bronzes are prone to porosity, while aluminum bronzes tend to form centralized shrinkage cavities. During the casting of C95400 copper alloy, appropriate measures need to be taken to address potential shrinkage cavities and porosity issues, such as selecting suitable solidification methods (sequential or simultaneous solidification). Its fluidity is also related to its composition. Aluminum bronzes and aluminum brasses exhibit good fluidity, whereas tin bronzes have poor fluidity. The fluidity of C95400 copper alloy falls within a certain range, and casting process parameters such as the gating system need to be designed based on its fluidity characteristics. The crystallization temperature range, solidification zone, and other crystallization characteristics of C95400 copper alloy have significant impacts on casting. Different copper alloy compositions exhibit distinct crystallization characteristics. For example, tin bronzes have a large solidification temperature range and a wide solidification zone, while aluminum bronzes and aluminum brasses have a small solidification temperature range and exhibit layer-by-layer consolidation characteristics. The crystallization characteristics of C95400 copper alloy fall between these two extremes, necessitating special casting processes to ensure molding quality.

Physical Properties

Processing Methods

During mechanical processing operations such as turning, milling, and drilling, appropriate cutting tools and processing parameters need to be selected for C95400 copper alloy due to its composition and performance characteristics. The presence of wear-resistant elements may affect the wear rate of the cutting tools, requiring adjustments based on actual conditions.

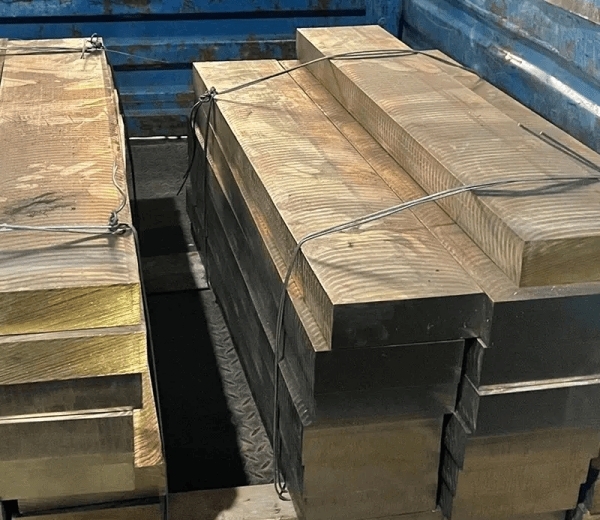

The casting processes for C95400 copper alloy are diverse. For example, the casting processes for round bars and plates vary according to their diameters or thicknesses. In round bar casting, diameters ranging from 1mm to 300mm have corresponding processes, including different forms of round bar processing such as rough rounds, turned rounds, forged rounds, polished rounds, and rolled rounds. For plates, thicknesses starting from 0.1mm up to 300mm are available in various processing forms such as rolled plates, forged plates, sheet materials, and forgings. Different processing forms are suitable for different subsequent application scenarios, and the casting process needs to consider factors such as composition and crystallization characteristics to optimize the process.

Mechanical Processing

Application Areas

With its certain electrical and thermal conductivity, C95400 copper alloy also has potential applications in electronic devices. For example, it can be used to manufacture heat sinks or small circuit connection components, playing a role in ensuring the normal operation of electronic devices.

Due to its wear resistance and structural properties, Mingxu Bearings widely uses C95400 copper alloy to manufacture various components in industrial machinery, such as bearings, gears, and bushings. These components play crucial roles in the normal operation of machinery, and C95400 copper alloy ensures their good performance during prolonged operation.

Market Supply

On the market, C95400 copper alloy is available in various specifications, ranging from round bars to plates, with different diameter and thickness specifications offered by corresponding suppliers. Mingxu Bearings provides C95400 copper alloy bar and sleeve components with diameters ranging from 1mm to 300mm, plate components with thicknesses starting from 0.1mm up to 300mm, as well as other non-standard customized components.

Development Prospects

With the continuous development of industry, the requirements for material performance are becoming increasingly stringent. The wear resistance and structural advantages of C95400 copper alloy position it for favorable development prospects in the future. In emerging fields such as intelligent manufacturing and high-end equipment manufacturing, C95400 copper alloy is expected to find wider applications. Meanwhile, with the advancement of materials science, ongoing optimization of its composition and performance will continue to meet new demands.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the R&D and production of copper alloy components and self-lubricating bearings for over a decade, boasting rich production experience and technical expertise. For any product or technical inquiries, please feel free to contact us: [email protected].

SF stands for three-layer composite, namely steel plate layer, copper powder layer and plastic layer. The steel plate layer plays the role of assembly...

See Details

MXB-JOLP self-lubricating wear plates have good self-lubricating properties and require no external lubrication. This product has good load-bearing ca...

See Details

MXB-JGLXS guide rails are parts installed on both sides of the side core-pulling slider to ensure that the side core-pulling slider moves back and for...

See Details

MXB-JGLX self-lubricating guide rails cover multiple properties such as high wear resistance, high temperature resistance, corrosion resistance, etc.,...

See Details

Constructed from high-grade graphite-copper alloy, the MXB-JSL L-type self-lubricating guide rail is strategically installed at the mold clamping guid...

See Details

Circular guides are frequently used in automobile panel molds and large stamping molds. The mold base and unloading plate guides usually use self-lubr...

See Details

SF-1T is a special formula product designed for high PV value working conditions of gear oil pump. The product has special advantages of fatigue resis...

See Details

SF-1P reciprocating bearing is a novel formula product designed based on the structure of SF-1X material and according to the special common condition...

See Details

SF-2X boundary lubricated bearing is based on steel plate, with sintered spherical bronze powder in the middle, modified polyoxymethylene (POM) rolled...

See Details

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

See Details

Contact Us