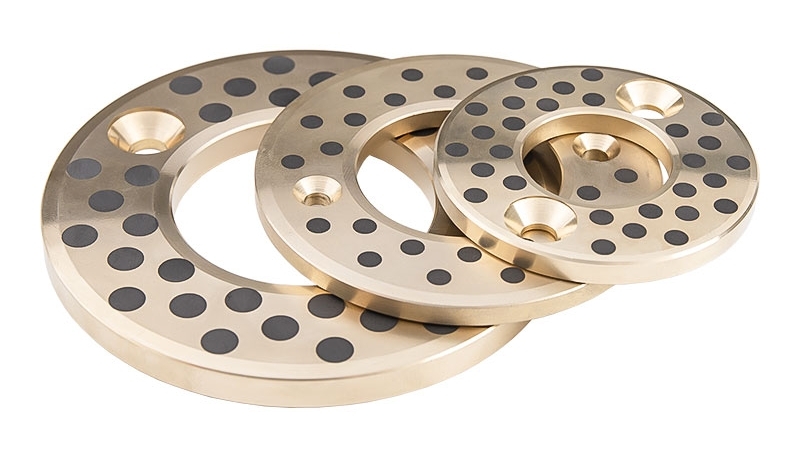

MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See DetailsIn the precise world of machinery, every tiny component bears enormous responsibility. The thrust washer, a seemingly simple yet highly functional component, is a crucial link in ensuring the stable operation of various hydraulic systems and mechanical equipment. From high-speed automotive engines to precision aerospace equipment, thrust washers have become an indispensable part of modern industry due to their unique properties and wide range of applications.

Thrust washers are typically made of metals (such as stainless steel, copper alloys), polymers (such as polytetrafluoroethylene), or reinforced fiber materials. They are designed as flat, disc-like structures similar to straight bearings but are specialized in withstanding axial loads. This design allows thrust washers to excel in environments with high loads, high-speed operation, or intermittent motion. Additionally, some high-end thrust washers, such as JTW copper-based self-lubricating thrust washers, incorporate solid lubricants that form a lubricating film during operation, further reducing the coefficient of friction and extending service life.

Product Performance:

l Wear resistance: Thrust washers undergo rigorous testing and exhibit excellent wear resistance, enabling long-term stable operation in high-speed and high-temperature environments and reducing equipment failure rates.

l Sealing performance: The high-precision manufacturing process ensures that thrust washers have good sealing effects, effectively preventing liquid or gas leaks and safeguarding system performance.

l Load-bearing capacity: Depending on the material and design, thrust washers can withstand axial loads ranging from a few newtons to several thousand newtons, meeting various application needs.

l Self-lubricating performance: Specific models of thrust washers, such as JTW copper-based self-lubricating thrust washers, have self-lubricating properties that can reduce the coefficient of friction to 0.02-0.08, significantly reducing wear and extending equipment life.

Product Advantages:

l High reliability: The application of thrust washers significantly improves the stability and reliability of mechanical systems, reducing downtime due to friction and wear.

l Long service life: Thanks to their excellent wear resistance and self-lubricating characteristics, thrust washers have a service life of several years, reducing maintenance costs and replacement frequency.

l Diversity: Thrust washers are available in various materials, sizes, and types to meet the needs of different industries and application scenarios, and custom services are also supported.

l Wide applicability: From automotive manufacturing to aerospace, from chemical production to electronic equipment, thrust washers have a wide range of applications and are an indispensable part of many industries.

Specific Application Scenarios:

l Automotive industry: In key components such as automotive engines, transmissions, and drive shafts, the application of thrust washers significantly improves mechanical efficiency and reliability, reducing failure rates. Statistics show that automotive engines using high-quality thrust washers can reduce failure rates by over 30%.

l Machinery manufacturing: In precision machinery equipment such as machine tools, printing presses, and textile machines, the use of thrust washers reduces friction and wear, improving processing accuracy and stability.

l Aerospace: In various high-precision equipment in the aerospace field, such as engines, landing gear, and hydraulic systems, thrust washers ensure safe operation of the equipment with their outstanding performance and reliability.

l Chemical industry: In chemical equipment such as pumps, valves, and reactors, thrust washers not only prevent leaks of corrosive media but also improve the equipment's corrosion resistance and service life.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. manufactures the JTW/JTWN series of thrust washers, which use high-strength brass embedded with high-quality graphite to further enhance product life and provide strong protection for your equipment. For orders, please contact: [email protected].

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

SF stands for three-layer composite, namely steel plate layer, copper powder layer and plastic layer. The steel plate layer plays the role of assembly...

See Details

MXB-JESW slide plates are 2-hole and 4-hole wear-resistant heavy-duty slide plates. They are standardized products and compatible with many brands, su...

See Details

MXB-JGLDW self-lubricating guide rails are made of high-strength brass through CNC machine tools. The surface is inlaid with solid lubricants such as ...

See Details

MXB-JTGLW self-lubricating guide rails provide resistance and reduce friction, ensuring extended durability and enhanced performance. This product pro...

See Details

MGB9834 DIN9834 standard guide bushing complies with DIN9843 standard and is suitable for European automotive stamping dies. It is designed to provide...

See Details

MJGB oil-free injection guide bushings are standard components used in the plastic injection molding process, providing lubrication-free guidance and ...

See Details

MX2000-2 nickel graphite dispersed alloy bearing is a new product among solid lubricating bearings. Compared with TF-1, this product has the character...

See Details

SF-1B bronze basic bearing is made of tin bronze as the base, sintered bronze spherical powder in the middle, and rolled PTFE and high temperature res...

See Details

SF-1S stainless steel corrosion-resistant bearing is a very effective corrosion-resistant material that is formed by rolling with stainless steel as t...

See Details

Contact Us