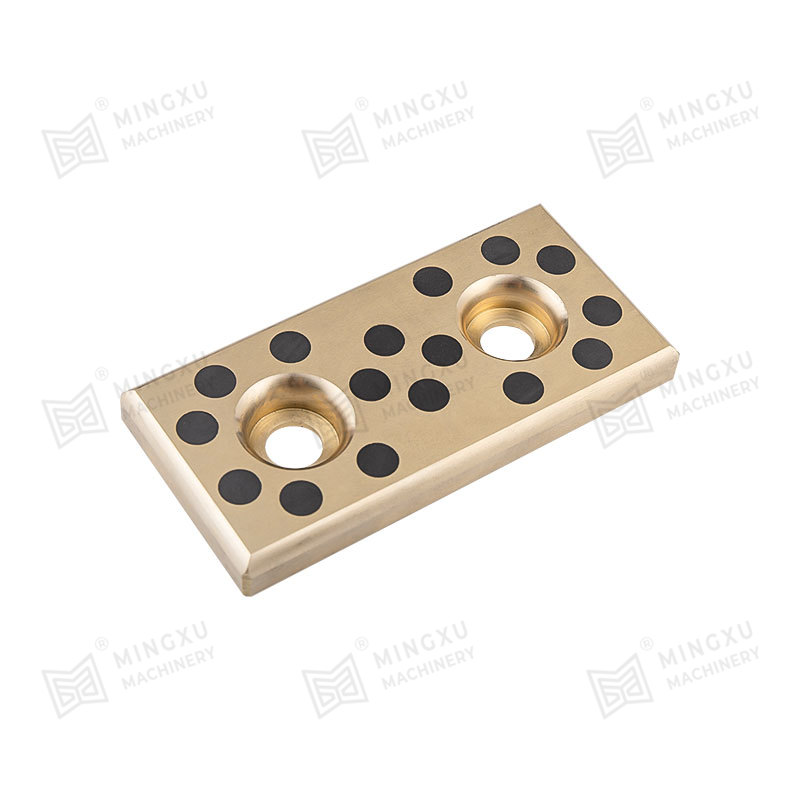

MXB-JTW Metric Thrust Washer For Vehicle Transmissions

Cat:Self-Lubricating Bearing

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See DetailsMaintenance-free bearings epitomize the convergence of tribology, materials science, and precision engineering, delivering unprecedented operational longevity in extreme environments from aerospace propulsion to subsea energy systems. This article dissects the multi-physics design frameworks, self-lubricating nanocomposites, and failure prediction algorithms that define next-generation maintenance-free bearing systems, while addressing challenges in high-cycle fatigue, contamination immunity, and cross-industry certification compliance.

Content

The operational permanence of maintenance-free bearings originates from atomic-scale material innovations:

Matrix Alloy Design:

Precipitation-hardened stainless steels (e.g., ASTM F1586) with 18% Cr, 10% Ni, and 3% Mo achieve 1,200 MPa UTS while resisting chloride-induced SCC (ASTM G36).

Powder metallurgy Fe-Cu-Sn-C composites enabling oil-less operation through controlled porosity (15–25% vol.) for lubricant reservoir functionality.

Solid Lubricant Integration:

Graphene-PTFE nanocomposite layers (50–200 μm) deposited via aerosol jet printing, reducing COF to 0.03 under 2.5 GPa Hertzian contact.

MXene (Ti₃C₂Tₓ) coatings demonstrating self-replenishing lubrication via shear-induced tribofilm formation.

Surface Engineering:

Laser shock peening inducing 500–800 MPa compressive residual stresses, enhancing RCF life by 300% (ISO 281 L10 calculations).

Diamond-like carbon (DLC) multilayer architectures (a-C:H/a-C:W) achieving <0.1 μm/1,000h wear rates in vacuum environments.

Advanced simulation frameworks optimize maintenance-free operation across operational envelopes:

Multi-Body Dynamics Modeling:

Discrete element method (DEM) simulations predicting particle contamination effects down to 5 μm debris size (ISO 16281 standards).

Transient thermal-structural coupling analyses for 180°C thermal gradient management in EV traction motors.

Lubrication Regime Control:

Micro-textured raceways (20–50 μm dimples) maintaining elastohydrodynamic (EHD) films under starved lubrication (λ ratio >1.5).

Magnetorheological fluid-incorporated cages dynamically adjusting viscosity by 10³ cP under 0.5T fields.

Vibration Signature Engineering:

Bio-inspired helical raceway geometries suppressing 1,200–2,500 Hz NVH frequencies through modal decoupling.

Autonomous tribological systems eliminate external intervention:

Phase-Change Lubricants:

Metallic glass alloys (Zr₆₅Cu₁₇.₅Ni₁₀Al₇.₅) releasing liquid-like layers at >250°C contact flash temperatures.

Paraffin-cored microcapsules (50–100 μm) rupturing under load to replenish WS₂ lubricant.

Biomimetic Self-Healing:

Diels-Alder polymer networks achieving 92% crack healing efficiency at 80°C within 30 minutes.

Microvascular networks circulating ionic liquid lubricants via capillary action (0.5–2 μL/hr flow rates).

Environmental Energy Harvesting:

Triboelectric nanogenerators (TENG) converting vibration energy (10–100 Hz) to power embedded condition monitoring sensors.

Validation protocols simulate decades of service in compressed timelines:

Enhanced ASTM D4172 Testing:

3,000-hour Four-Ball tests under 4 GPa contact stress with in-situ μ-Raman wear mechanism analysis.

Combined fretting-corrosion testing per ASTM G204 with 5% NaCl mist exposure.

Digital Twin Prognostics:

Physics-informed neural networks (PINN) predicting L₅₀ life within ±5% accuracy using 12 operational parameters.

Blockchain-immutable lifetime records integrating 20+ sensor data streams (vibration, temperature, acoustic emissions).

Contamination Resilience Testing:

ISO 12103-1 A3 Fine Test Dust ingestion at 0.1 g/hr rates during 10⁹ revolution endurance trials.

Case Study: Siemens Gamesa’s 15 MW turbine employs maintenance-free spherical roller bearings with:

TaC-reinforced Si₃N₄ hybrid ceramics (HV1,800)

120-year design life under 7 MW variable torque loading

-40°C cold start capability via phase-stable lubricants

Airbus A350 Flap Track Bearings:

MoS₂/TiN multilayer coatings (0.2 μm thickness gradient)

15,000 flight cycles without relubrication

50% weight reduction vs. conventional steel bearings

MRI-Compatible Surgical Arm Bearings:

ZrO₂-Al₂O₃ composites with <0.01 ppm metallic ions release

0.5 μm positioning repeatability under 10⁴ N radial loads

Next-gen bearings align with ISO 14040 LCA standards through:

Regenerative Manufacturing:

95% metal powder reuse in binder jetting processes (ASTM F42 standards).

CO₂-negative graphene production via methane pyrolysis.

Self-Disassembly Mechanisms:

Shape-memory polymer cages releasing components at 150°C for effortless recycling.

Electrochemical de-bonding of DLC coatings for substrate reclamation.

Bio-Based Lubricants:

Epoxidized soybean oil formulations achieving 80% biodegradation in 28 days (OECD 301B).

Quantum Tribology:

Electron density functional theory (DFT) optimizing 2D lubricant interlayer spacings.

Superlubricity states in graphene-hBN heterostructures under UHV conditions.

IoT-Enabled Bearings:

Embedded MEMS sensors (<1 mm³) monitoring real-time μ-level lubricant film thickness.

Edge-AI chips executing remaining useful life (RUL) predictions every 10⁶ cycles.

4D-Printed Adaptive Bearings:

Humidity-responsive hydrogel raceways adjusting clearance by ±5 μm.

Magnetic shape memory alloys self-adjusting preload under variable speeds.

Market analysts (Frost & Sullivan, 2027) project 9.8% CAGR for maintenance-free bearings, driven by renewable energy and Industry 4.0 adoption.

MXB-JTW metric thrust washers are based on high-strength brass (ZCuZn25Al6), with solid lubricant (graphite or molybdenum disulfide) embedded in the m...

See Details

Mining machinery and equipment are very easy to wear during use. In order to extend the service life of the equipment, Mingxu Machinery recommends tha...

See Details

MXB-JGLDW self-lubricating guide rails are made of high-strength brass through CNC machine tools. The surface is inlaid with solid lubricants such as ...

See Details

MXB-JTGLW self-lubricating guide rails provide resistance and reduce friction, ensuring extended durability and enhanced performance. This product pro...

See Details

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MX2000-2 nickel graphite dispersed alloy bearing is a new product among solid lubricating bearings. Compared with TF-1, this product has the character...

See Details

SF-1X oil-free lubricating bearing is a rolled sliding bearing with steel plate as the base, spherical bronze powder sintered in the middle, and a mix...

See Details

SF-1D hydraulic bearing is a new type of material designed based on SF-1P and combining the working principle of oil cylinder and shock absorber. It i...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

FB092 bronze punch bearings are made of bronze material as the base, with uniform and orderly oil injection holes processed. They are rolled into thin...

See Details

Contact Us