As the name suggests, high-strength brass is a type of brass with high mechanical properties. The term originates from the common designation in Japan for the CAC300 series of brass. Mingxu Bearing is one of the major domestic suppliers of high-strength brass products. High-strength brass is a high-strength, high-hardness copper alloy material composed mainly of copper and zinc, with the addition of alloy elements such as aluminum, iron, and manganese. Due to its excellent mechanical properties and wear resistance, it finds widespread applications in the industrial sector. The following provides an overview from four aspects: definition, composition, properties, and applications.

1. Definition

High-strength brass belongs to a category of special brass. It is a multi-element alloy formed by adding elements like aluminum, iron, and manganese to a copper-zinc alloy. The term "high-strength" in its name reflects its high strength and hardness, making it suitable for applications that require withstanding high loads and wear.

2. Composition

The main components of high-strength brass include:

- Copper (Cu): The base element, with a content typically ranging from 60% to 70%.

- Zinc (Zn): The primary alloy element, with a content of approximately 20% to 30%.

- Aluminum (Al): Enhances strength, hardness, and corrosion resistance.

- Iron (Fe): Refines grain structure and improves wear resistance.

- Manganese (Mn): Improves the mechanical and casting properties of the alloy.

A typical chemical formula is ZCuZn25Al6Fe3Mn3, indicating approximately 65% copper, 24% zinc, 6% aluminum, 3% iron, and 3% manganese.

3. Properties

High-strength brass exhibits the following notable properties:

- High strength and hardness: With a tensile strength exceeding 700 MPa and a Brinell hardness (HB) greater than 200, it can withstand significant mechanical stress.

- Excellent wear resistance: Suitable for high-friction, high-wear environments, extending service life.

- Good corrosion resistance: Resistant to most acids, alkalis, and salt solutions, making it suitable for corrosive environments such as marine and chemical applications.

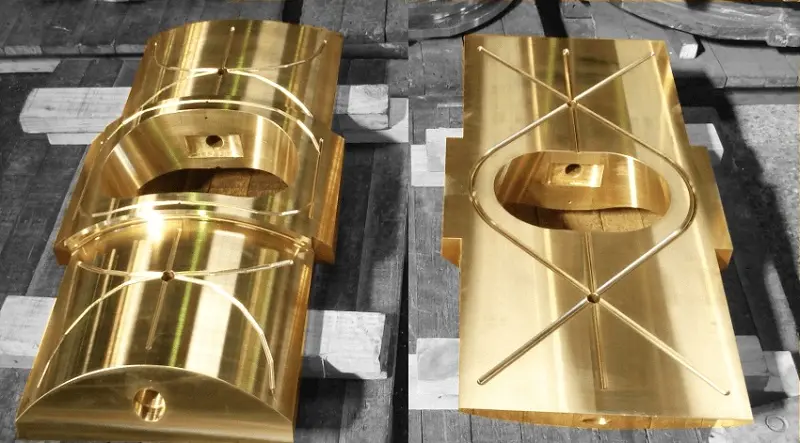

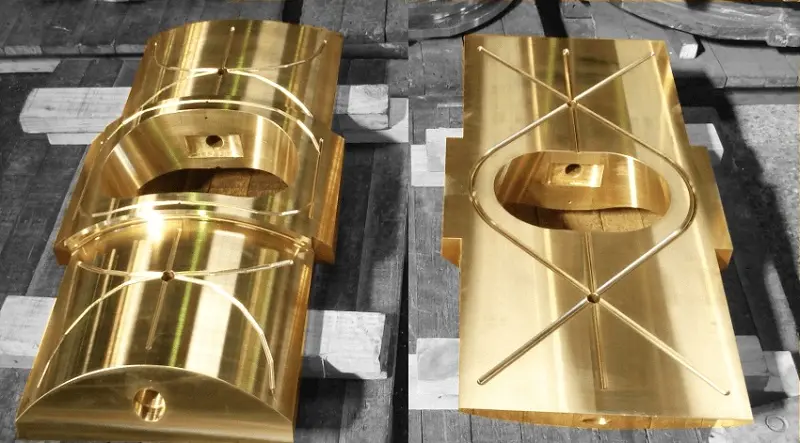

- Good workability: Possesses good plasticity and machinability, allowing it to be processed into complex-shaped parts through various processes such as casting, forging, and cutting.

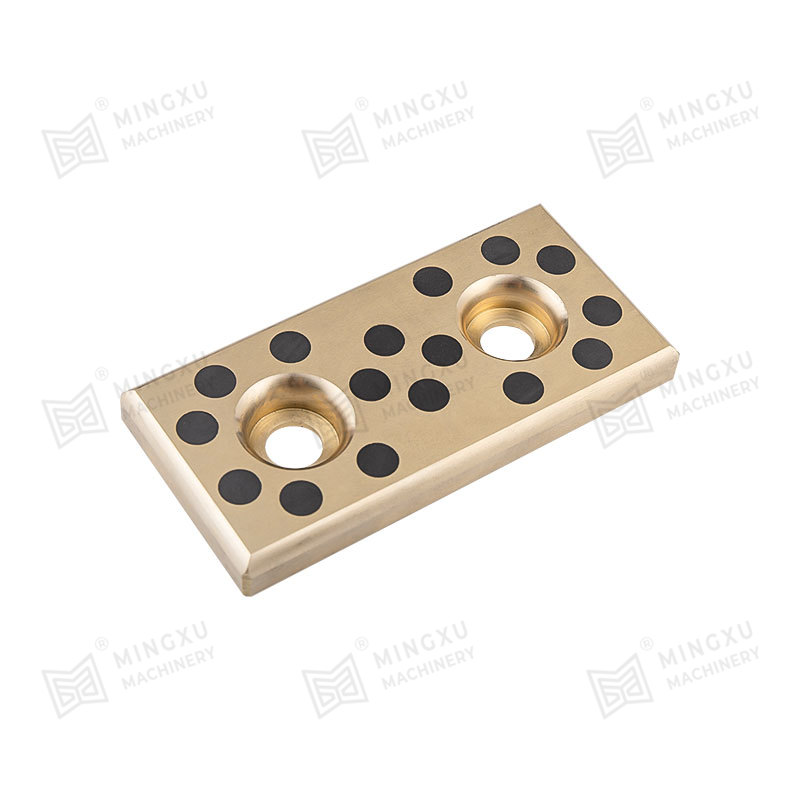

- Self-lubricating properties: Some high-strength brass products (e.g., solid lubrication oil-free bearings) achieve oil-free lubrication by embedding lubricating materials like graphite or molybdenum disulfide, reducing friction coefficients.

4. Applications

Due to its excellent properties, Mingxu Bearing extensively applies high-strength brass in the following fields:

- Bearings and bushings: Used in manufacturing high-load, oil-free lubricated bearings and bushings for applications such as construction machinery, mining equipment, and automotive engines.

- Gears and worms: Suitable for manufacturing high-strength, high-wear-resistant gears and worms.

- Valves and pipelines: Used in manufacturing corrosion-resistant valves, pipelines, and fittings for industries such as chemicals, petroleum, and marine.

- Molds and tools: Employed in manufacturing high-hardness, wear-resistant molds and tools, such as stamping dies and cutting tools.

- Mechanical parts: Suitable for manufacturing mechanical parts requiring high strength and wear resistance, such as bolts, nuts, and shaft components.

According to the Japanese JIS standard, high-strength brass is classified into four types within the CAC300 series: CAC301, CAC302, CAC303, and CAC304. Below is a brief introduction to these four types:

CAC301:

- Alloy type: Cu-Zn-Al-Fe-Mn.

- Alloy characteristics: Good hardness and corrosion resistance, with excellent machinability.

- Typical applications: Suitable for pipe fittings and wear-resistant parts with lower requirements.

CAC302:

- Alloy type: Cu-Zn-Al-Fe-Mn.

- Alloy characteristics: High strength, good wear resistance, higher hardness than CAC301, and weldable.

- Typical applications: Suitable for marine bearings and bearing retainers, die-casting parts, and corrosion-resistant parts in shipbuilding and machinery manufacturing.

CAC303:

- Alloy type: Cu-Zn-Al-Fe-Mn.

- Alloy characteristics: Exceptionally high strength and hardness, suitable for wear-resistant parts under high loads.

- Typical applications: Suitable for low-speed, high-load wear/corrosion-resistant parts, such as large castings like marine propellers.

CAC304:

- Alloy type: Cu-Zn-Al-Fe-Mn.

- Alloy characteristics: The highest hardness and compressive strength among high-strength brass casting alloys, suitable for high-load wear/corrosion-resistant applications.

- Typical applications: Suitable for low-speed, high-load vibrating parts, such as solid self-lubricating bearings, inlaid self-lubricating components, bridge support wear plates, hydraulic gate bearings, hoist copper sleeves, sliders, and worms.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the R&D and production of copper alloy components and self-lubricating bearings for over a decade, with rich production experience and technical expertise. For any product or technical inquiries, please feel free to contact us: [email protected].

English

English Español

Español

Contact Us