As a core component of modern precision transmission systems, linear bearings hold a pivotal position in automated equipment, precision instruments, and high-speed motion applications due to their high precision, low friction, and modular design characteristics. With the rapid development of intelligent manufacturing and new energy sectors, linear bearings have further enhanced load efficiency and service life through optimized structural materials and lubrication technologies, becoming standard components in fields such as industrial robots, CNC machine tools, and 3C electronic devices.

Core Application Advantages of Linear Bearings

High Precision and Repeatable Positioning

Linear bearings employ ball or roller recirculation structures, achieving friction coefficients as low as 0.001–0.003 (ISO 14728 standard). When paired with high-rigidity guide rails, they enable micron-level repeatable positioning accuracy, meeting the ultra-precision requirements of semiconductor lithography machines, medical inspection equipment, and other critical applications.

High-Speed and Low-Friction Performance

Optimized raceway designs (e.g., Gothic arch grooves) minimize sliding friction of rolling elements, supporting linear speeds of 5–10 m/s. This significantly improves cycle efficiency in automated production lines (e.g., lithium-ion battery winding machines), reducing energy consumption by 15%–20% (CATL 2023 Technical White Paper).

Modular and Lightweight Design

Standardized flange, square, or round housing structures support plug-and-play installation, adapting to diverse mounting spaces. Materials like aluminum alloy or engineering plastics achieve weight reductions of 30%–50%, making them widely used in drone gimbals and collaborative robot joints.

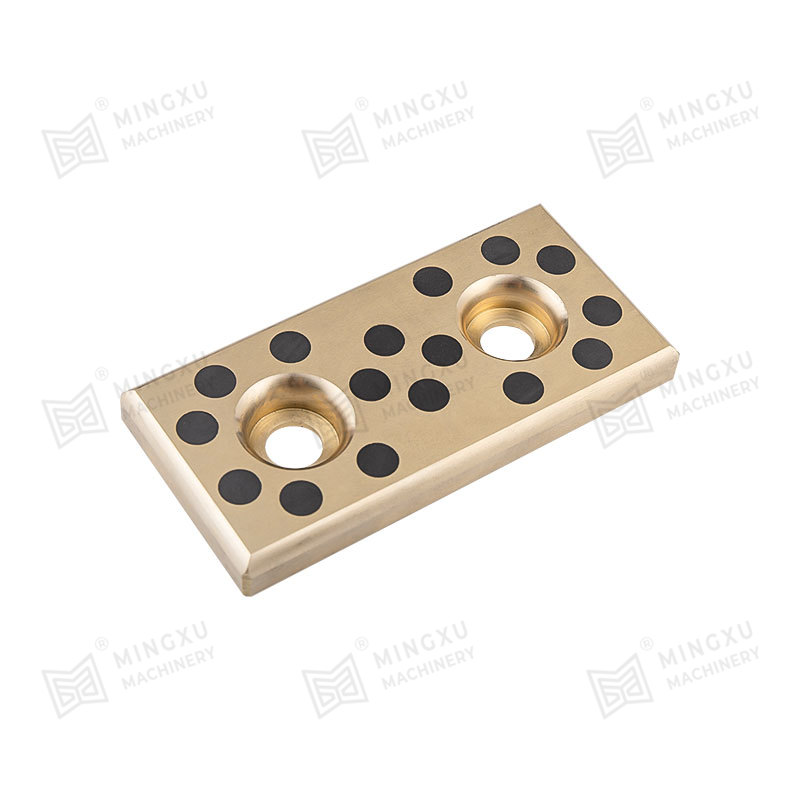

Contamination Resistance and Maintenance-Free Operation

Sealed designs (IP54/IP65 protection ratings) block dust and cutting fluid infiltration. When combined with self-lubricating bushings or solid lubricant coatings, they enable maintenance-free operation exceeding 10,000 hours in humid, dusty environments such as food packaging machinery and textile equipment (Bosch Rexroth 2022 case study).

High Load Capacity and Long Service Life

Multi-row ball layouts and hardened steel rails (HRC 58–62) provide dynamic load capacities of 10–50 kN, with service life calculations (L10) exceeding 5,000 km. This makes them suitable for high-intensity applications like heavy-duty stamping presses and logistics sorting robotic arms.

Wide Temperature Adaptability

Specialty lubricating greases (–40°C to 150°C) and stainless steel bearings withstand extreme temperature environments, such as cold storage handling robots and automotive welding lines, with performance fluctuation rates below 5% (Fanuc 2021 test report).

Typical Industry Applications (2020–2023)

l New Energy Sector: BYD's blade battery production lines utilize linear bearing modules to achieve high-speed sorting of 300 battery cells per minute with positioning errors ≤±0.1 mm (2023 public technology demonstration).

l Semiconductor Manufacturing: In ASML's EUV lithography machines, linear bearings paired with magnetic levitation drives achieve 0.1 nm-level motion smoothness, supporting mass production of chips below 7 nm (industry research data).

l Medical Equipment: Siemens' CT machine slip ring systems incorporate linear bearings to ensure zero-jitter operation during 360° rotational scans, improving image resolution to 0.2 mm (2022 Medical Equipment Exhibition case study).

Linear bearings have demonstrated their performance in high-speed, high-load, and complex environments through precision manufacturing and scenario-driven innovations, earning global industrial validation. Their technological advancements continue to drive automation equipment toward greater efficiency and reliability, with significant potential for emerging fields such as AI equipment and space exploration.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd., with over a decade of expertise in bearing manufacturing, offers high-quality linear bearings alongside self-lubricating bearings, providing customers with a seamless supporting experience. For procurement inquiries, please contact us at [email protected].

English

English Español

Español

Contact Us