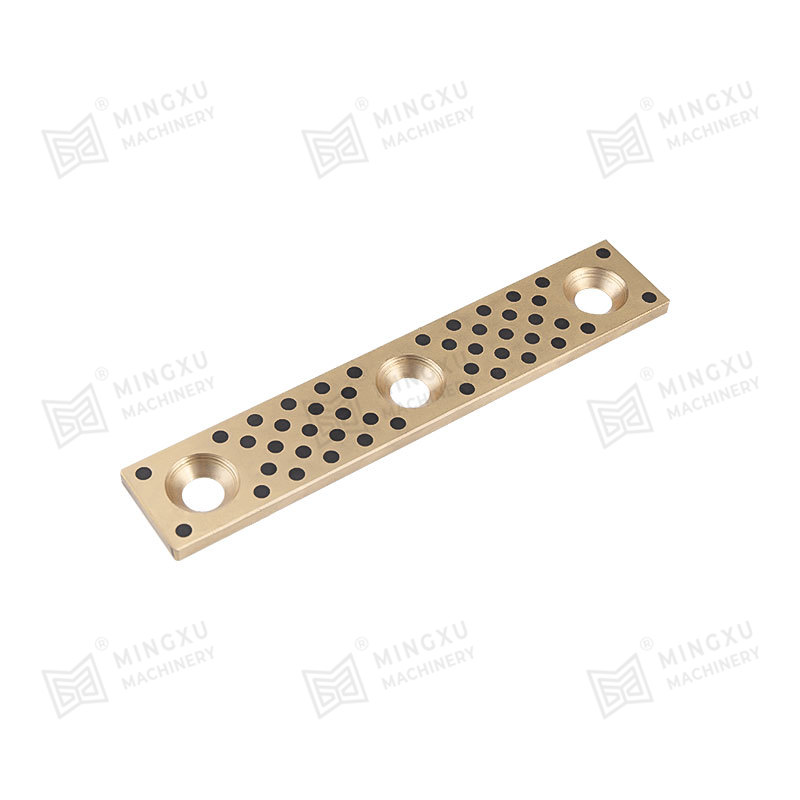

MXB-JFFB Self-Lubricating Half Bearing

Cat:Self-Lubricating Bearing

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See DetailsConstruction machinery operates in extreme environments characterized by high impact loads, heavy dust, and wet, muddy conditions. Traditional bearings frequently fail due to grease loss, contamination-induced seizing, and accelerated wear, significantly reducing equipment availability. Self-lubricating bearings, renowned for their maintenance-free operation, contamination resistance, and impact durability, are becoming standard components in excavators, loaders, and other heavy equipment.

1. Typical Applications in Construction Machinery

1.1 Excavator Slewing Bearings and Boom Joints

l Slewing Ring Support: Large slewing bearings (>2 m diameter) utilize copper-based graphite-inlaid bearings to withstand axial loads up to 300 tons. Sany Heavy Industry tests demonstrate that, after 2,000 hours of continuous operation in muddy conditions, wear is only 0.08 mm—70% longer than grease-lubricated bearings.

l Boom Articulation Points: High-chromium steel-backed self-lubricating bearings endure peak impact loads exceeding 80 MPa during excavation. Retrofitting a Komatsu excavator reduced annual articulation joint maintenance from 8 times to 1 time.

1.2 Loader Transmission Systems

l Transmission Thrust Bearings: PTFE fiber-reinforced composite bearings maintain a stable friction coefficient of 0.05–0.08 under frequent gear-shifting conditions. Tests on a LiuGong 5-ton loader showed a 3% improvement in transmission efficiency and a 5% reduction in fuel consumption.

l Differential Planetary Gear Shafts: Metal-based self-lubricating bearings (steel back + copper powder sintered layer) withstand surface pressures up to 50 MPa. Caterpillar case studies indicate that, in sandy oil environments, bearing life extends to 8,000 hours—double that of conventional solutions.

1.3 Bulldozer Track Running Gear

l Track Roller Bearings: Engineering plastic-based self-lubricating bearings (e.g., PEEK + carbon fiber) resist mud immersion and gravel impact. Tests on Shantui’s SD22 bulldozer show that track roller replacement cycles increased from 1,200 to 3,000 hours, reducing maintenance costs by 60%.

l Idler Adjustment Mechanisms: Graphite-inlaid stainless steel bearings exhibit an annual corrosion rate <0.005 mm in acidic/alkaline soil. XCMG’s African mine site trials demonstrated 2 years of failure-free operation.

1.4 Truck Crane Telescopic Boom Systems

l Boom Slider Bearings: Ultra-high molecular weight polyethylene (UHMWPE)-based bearings reduce friction coefficients to 0.1. Tests on Zoomlion’s 100-ton crane improved telescoping smoothness by 40% and reduced cylinder pressure fluctuations by 25%.

l Winch Bearing Housings: Self-lubricating spherical plain bearings (e.g., GE60ES) withstand 120 kN dynamic loads at 15° misalignment. Liebherr case studies show a 3x improvement in fretting wear resistance.

2. Key Selection Criteria and Technical Specifications

2.1 Contamination Resistance and Sealing Design

l Construction sites often exceed 50 mg/m³ dust concentrations, necessitating bearings with labyrinth or PTFE lip seals.

l Third-party testing shows that self-lubricating bearings with integrated seals reduce internal contamination by 95% (1/20th of open-type bearings) after 500 hours in ISO 12103-A3 dust tests.

2.2 Impact Resistance and Fatigue Strength

l Per ISO 4378-1, construction machinery bearings must pass ≥10⁷ impact cycle tests (±30% load fluctuations).

l Volvo Construction Equipment tests show that steel-backed copper powder sintered bearings achieve 8 million fatigue cycles without cracking at 2,000 impacts/minute.

2.3 Temperature Adaptability

|

Operating Environment |

Temperature Range |

Recommended Materials |

|

Hydraulic system vicinity |

-40°C to +150°C |

Metal-based sintered materials (with MoS₂) |

|

Engine compartments |

Localized 200°C spikes |

Graphite-copper composites |

|

Arctic operations |

-55°C to +80°C |

PI (polyimide)-based bearings |

2.4 Load and Speed Matching

l Low-Speed, Heavy-Load (e.g., Bulldozer Blade Pivots): Copper-based sintered bearings with surface pressure ratings ≥80 MPa (ASTM B438 compliant).

l High-Speed Oscillation (e.g., Excavator Bucket Cylinders): POM-based bearings allow oscillation frequencies up to 30 cycles/minute (50% higher than metal bearings).

2.5 Cost-Effectiveness Evaluation

The 2023 Global Construction Machinery Bearing Market Report indicates that oil-free bearings reduce total costs by 18–25% compared to conventional solutions:

l Caterpillar D6 bulldozer annual maintenance costs dropped from 12,000to8,500.

l Sany SY215 excavator bearing replacement time reduced from 4 hours to 1.5 hours.

3. Industry Trends and Selection Recommendations

3.1 Technological Frontiers

l Self-Healing Coatings: EP15 coatings by UK-based GGB deposit lubricating films at worn areas, extending life by 30%.

l Lightweight Designs: Carbon fiber-reinforced composite bearings are 60% lighter than steel equivalents and are used in aerial work platform boom systems.

3.2 Practical Selection Tips

l Prioritize products certified to ISO 4378 (sliding bearing testing) and GB/T 2889 (construction machinery bearing standards).

l Construction machinery bearings require 0.1–0.3 mm thermal expansion clearances (calculated based on CTE matching).

l Request vendor-provided mud immersion + vibration composite test reports (preferably including 500-hour salt spray + 2 million impact tests).

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has specialized in self-lubricating bearing R&D and manufacturing for over a decade, with a strong customer base and trust in the construction machinery sector. For inquiries, contact: [email protected].

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See Details

MXB-JDB self-lubricating bearings, also known as graphite inlaid bronze bushings, are novel lubricating bearings that have both the characteristics of...

See Details

MXB-JUWP self-lubricating wear-resistant plate is a 5mm thick self-lubricating graphite inlaid wear-resistant plate developed and produced by Mingxu M...

See Details

MXB-JOML self-lubricating wear plates are designed to minimize friction and extend service life in industrial applications. The product is made from a...

See Details

MXB-JTGLW self-lubricating guide rails provide resistance and reduce friction, ensuring extended durability and enhanced performance. This product pro...

See Details

MGB9834 DIN9834 standard guide bushing complies with DIN9843 standard and is suitable for European automotive stamping dies. It is designed to provide...

See Details

MX2000-1 graphite embedded alloy bearing, MX2000-1 graphite scattered alloy bearing is an improved product of JF800 bimetallic bearing. It has the pre...

See Details

SF-1W lead-free bearing is a new product developed based on SF-1X material according to international environmental protection requirements. In additi...

See Details

SF-1S stainless steel corrosion-resistant bearing is a very effective corrosion-resistant material that is formed by rolling with stainless steel as t...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

Contact Us