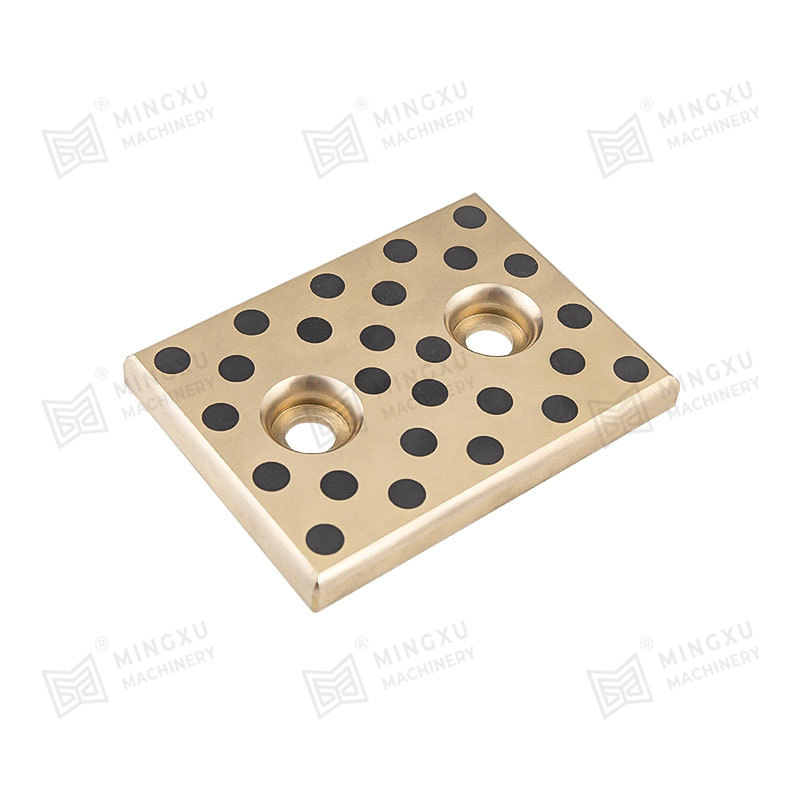

Graphite bronze plates are widely used in various industrial applications requiring low friction, wear resistance, and reliable operation under heavy loads or harsh environments. Their unique combination of bronze alloy strength and the solid lubrication properties of graphite makes them ideal for bearings, bushings, and sliding components where external lubrication is difficult or undesirable.

At the heart of their functionality is the graphite content and its distribution within the bronze matrix, which critically influences the self-lubricating performance, wear characteristics, and mechanical integrity of the composite material.

Role of Graphite in Bronze Plates: Basics of Self-Lubrication

Graphite acts as a solid lubricant due to its layered crystal structure, where weak van der Waals forces between layers allow easy shear under sliding motion, reducing friction significantly. In a bronze matrix, graphite inclusions provide continuous lubrication at the sliding interface without the need for oil or grease, leading to lower maintenance and longer service life.

The effectiveness of this self-lubrication depends heavily on:

Graphite content (percentage by volume or weight)

Size and shape of graphite particles

Uniformity of graphite dispersion throughout the bronze matrix

Influence of Graphite Content on Lubricating Performance

a. Low Graphite Content (<5%)

At low graphite levels, lubrication is limited because graphite particles are sparse and may not form a continuous lubricating film on the sliding surface.

Friction reduction is marginal, and wear resistance may suffer due to insufficient solid lubricant presence.

The bronze matrix dominates mechanical properties, preserving higher strength and hardness but sacrificing lubrication.

b. Moderate Graphite Content (5–15%)

This range often represents a balanced composition where graphite is sufficient to form stable lubricating films on the surface during operation.

The friction coefficient significantly decreases, and wear rates improve due to continuous graphite transfer to the mating surface.

Mechanical strength and toughness are still acceptable for most bearing and sliding applications.

Many commercial graphite bronze plates are formulated within this range.

c. High Graphite Content (>15%)

Excess graphite leads to abundant lubrication but compromises mechanical integrity and load-carrying capacity.

The bronze matrix weakens as graphite particles act like defects or voids, reducing strength, fatigue resistance, and wear life under heavy loads.

High graphite content is used only when lubrication is critical, and mechanical stresses are moderate.

Effect of Graphite Distribution and Particle Characteristics

a. Uniform Distribution

Homogeneous dispersion of graphite ensures consistent self-lubrication across the entire bearing surface.

Avoids localized wear and friction hotspots that occur if graphite clusters or agglomerates form.

Leads to predictable and stable friction behavior and longer component life.

b. Non-Uniform or Clustered Distribution

Graphite agglomerates or uneven dispersion cause weak points in the bronze matrix.

Results in premature mechanical failure or surface fatigue.

May lead to inconsistent lubrication performance, with some areas experiencing high friction and others being overly lubricated.

c. Particle Size and Shape

Fine, well-distributed graphite particles provide better surface coverage and smoother lubrication films.

Larger graphite particles improve lubrication but can reduce matrix cohesion.

Spherical or flake graphite shapes influence the ease of shear and transfer to the sliding interface.

Lubrication Mechanism: Graphite Transfer Film Formation

During sliding, graphite particles near the contact surface shear off and form a thin transfer film on the mating surface. This film reduces direct metal-to-metal contact, thus lowering friction and wear. The thickness, continuity, and stability of this transfer film depend on graphite content and distribution:

Adequate graphite levels ensure the transfer film replenishes continuously under wear conditions.

Uniform graphite dispersal maintains consistent film formation over the sliding area.

Insufficient or uneven graphite leads to thin or patchy transfer films, reducing lubrication efficacy.

Trade-Offs Between Lubrication and Mechanical Properties

Optimizing graphite content and distribution is a balancing act:

Increasing graphite improves lubrication but weakens mechanical strength and wear resistance under high loads.

Ensuring uniform distribution minimizes mechanical degradation and improves overall performance.

Manufacturers tailor graphite bronze plate formulations based on specific application demands, balancing load, speed, temperature, and lubrication needs.

Manufacturing Considerations for Optimal Graphite Dispersion

Powder Metallurgy: Most graphite bronze plates are produced by powder metallurgy, allowing precise control over graphite quantity and distribution by blending powders before sintering.

Casting and Machining: Alternative methods may struggle to achieve uniform graphite dispersion, leading to compromised properties.

Quality Control: Techniques like microscopy, X-ray diffraction, and hardness testing are used to assess graphite dispersion and optimize process parameters.

The graphite content and its distribution within the bronze matrix are the most critical factors governing the self-lubricating performance of graphite bronze plates. Moderate graphite content (5–15%) with uniform particle dispersion delivers optimal lubrication while maintaining mechanical strength and durability. Proper manufacturing techniques ensure this balance, enabling graphite bronze plates to meet demanding industrial applications where maintenance-free, low-friction operation is essential.

English

English Español

Español

Contact Us