In demanding industrial applications, bearing components are frequently subjected to conditions involving high loads, high speeds, or a combination of both. Under such circumstances, traditional bushings that rely on periodic manual lubrication can face significant limitations, including lubricant breakdown, increased wear, and the risk of failure due to overheating or metal-on-metal contact. Self-lubricating bushings, by contrast, are specifically engineered to address these challenges through materials and design features that allow them to perform reliably without the need for external lubrication.

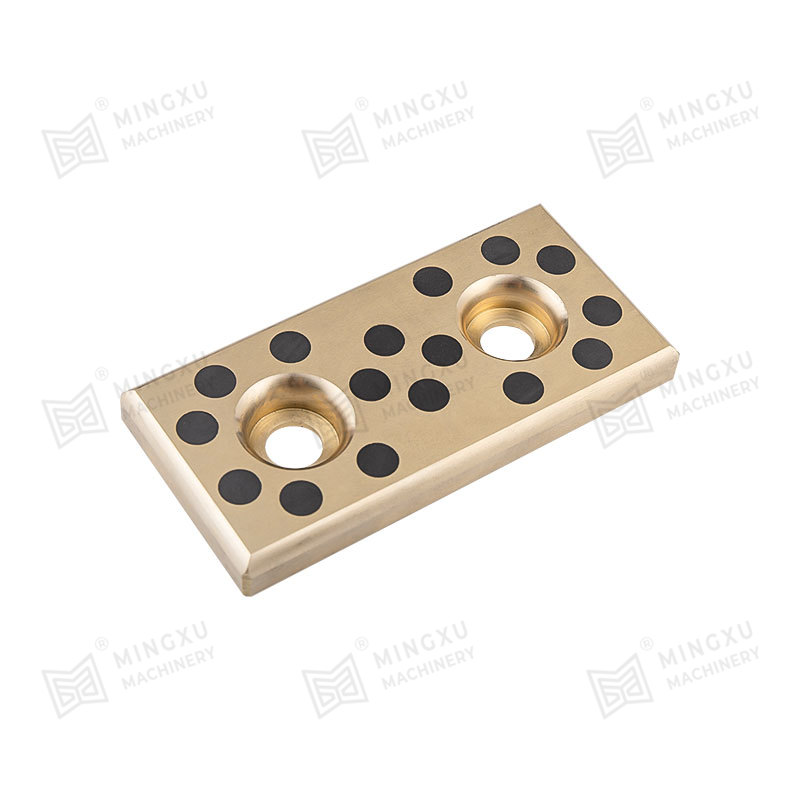

Under heavy load conditions, self-lubricating bushings maintain performance by leveraging internal lubrication agents that are integrated directly into the structure of the bushing material. These agents—often in the form of embedded solid lubricants like graphite, PTFE (polytetrafluoroethylene), or molybdenum disulfide—are gradually released during operation as frictional heat and pressure increase. This mechanism creates a low-friction film between the mating surfaces, effectively reducing wear and preventing surface damage even when load pressures reach or exceed 50 to 100 MPa, depending on the material type. In metal-based bushings such as sintered bronze or copper alloys with embedded graphite plugs, this effect is especially pronounced. These bushings can endure high compressive forces while continuing to operate with minimal friction and consistent performance over extended cycles.

Polymer-based self-lubricating bushings, while generally offering lower load capacity than their metal counterparts, also perform well under moderate to heavy loads, particularly when made from high-performance materials such as PEEK, PTFE composites, or thermoplastics reinforced with fibers. These materials not only provide low-friction operation but also exhibit excellent resistance to corrosion, chemical exposure, and moisture—making them ideal for environments where both load stress and environmental factors are present. However, it is important to note that polymer bushings may deform or wear faster if the applied load consistently exceeds their specified limits.

When it comes to high-speed applications, self-lubricating bushings again offer significant advantages. The embedded lubricants reduce friction at the interface between moving parts, which minimizes the generation of heat during rapid motion. This is particularly critical in high-RPM machinery, where traditional lubrication systems may fail to provide consistent coverage, especially in areas where centrifugal force may displace oil or grease. Self-lubricating bushings mitigate this risk by ensuring that a lubricating layer is always present, regardless of motion direction or rotation speed.

Thermal stability becomes a key performance indicator at high speeds. Metal-based self-lubricating bushings generally exhibit higher thermal conductivity and better resistance to high temperatures, allowing them to dissipate frictional heat effectively and avoid thermal deformation. This makes them suitable for high-speed rotating shafts, compressors, and heavy-duty gear systems. On the other hand, advanced polymer bushings can also perform at elevated speeds, provided that the temperature stays within the material's thermal limits. Many engineered plastics used in self-lubricating bushings have PV (pressure × velocity) ratings that can exceed 30 MPa·m/s, making them capable of handling a wide range of speed and load combinations without excessive wear.

The combination of self-lubrication, low maintenance requirements, and consistent performance under dynamic load and speed conditions makes these bushings highly suitable for critical applications in industries such as automotive, aerospace, construction machinery, packaging equipment, and food processing. In these sectors, reducing downtime, eliminating the need for periodic lubrication, and maintaining stable operation are all essential for long-term efficiency and cost control.

Self-lubricating bushings perform remarkably well under both heavy loads and high-speed scenarios, provided that the appropriate material and design are selected for the specific application. Metal-based bushings are generally preferred in extreme load or thermal conditions, while polymer-based bushings offer benefits in applications requiring low weight, corrosion resistance, or silent operation. Both types contribute to longer equipment life, reduced maintenance, and improved operational reliability in high-demand environments.

English

English Español

Español

Contact Us