MXB-JFFB Self-Lubricating Half Bearing

Cat:Self-Lubricating Bearing

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See Details

JDB self-lubricating bearings

JDB self-lubricating bearings are specially designed bearings produced by Zhejiang Mingxu Machinery Manufacturing Co., Ltd., which combine the characteristics of metal bearings and self-lubricating bearings. They have a wide range of applications. The working conditions that are suitable for them mainly include the following aspects:

1. Heavy-load and low-speed occasions

High load capacity: JDB self-lubricating bearings can withstand higher loads due to the use of high-strength metal substrates (such as high-strength brass, tin-phosphor bronze, bearing steel, etc.).

Low-speed operation: This bearing is particularly suitable for low-speed operation conditions and can maintain good lubrication effect and stability at low speeds.

2. Harsh environmental conditions

High temperature environment: JDB self-lubricating bearings have the characteristics of high temperature resistance, can operate stably in high temperature environments, and are not easily invalidated due to temperature increases.

Environment with large dust or corrosive gases: In harsh environments with large dust or acidic corrosive gases (such as CO, SO2, etc.) in the air, traditional oil and grease lubrication methods are often difficult to handle, while JDB self-lubricating bearings can effectively reduce friction and wear and extend service life through their self-lubricating characteristics.

3. Underwater and seawater conditions

Underwater application: For underwater and seawater conditions, the SL4 solid lubricant (mainly composed of PTFE+MoS2+CF) in JDB self-lubricating bearings can provide extremely low friction coefficient and good self-lubricating properties, ensuring that the bearings can maintain stable lubrication in underwater environments.

4. Specific application areas

Metallurgical continuous casting machines, train brackets, rolling equipment, mining machinery: These equipment often need to operate under high temperature, high load, low speed and heavy load conditions, and JDB self-lubricating bearings can meet their lubrication needs.

Ships, steam turbines, and water turbines: In industries such as ships and hydropower generation, the water resistance and corrosion resistance of JDB self-lubricating bearings make them an ideal choice.

Light industry machinery and machine tool industry: Under low load, high temperature, medium speed and other conditions, JDB self-lubricating bearings are also widely used.

Support parts of lifting machinery: such as winch support, crane support, excavator support, etc. The superior performance of JDB self-lubricating bearings can ensure the stable operation of these equipment under harsh conditions.

5. Technical Features

Self-lubricating properties: JDB self-lubricating bearings achieve self-lubrication in the absence of oil or less oil by embedding solid lubricants (such as graphite, PTFE+MoS2, etc.) on a high-strength metal matrix, reducing maintenance costs and downtime.

High wear resistance and compressive strength: The bearing has excellent wear resistance and compressive strength, and can maintain long-term stable operation under harsh working conditions.

Flexible design and strong adaptability: The end face of the JDB self-lubricating bearing can be welded and installed with the matrix, and is suitable for various fields and working conditions where oil cannot be added.

In summary, JDB self-lubricating bearings are suitable for lubrication needs under various complex working conditions such as heavy load and low speed, harsh environment, underwater and seawater conditions. Its excellent performance and wide application fields make it an indispensable and important component in modern industry.

Zhejiang Mingxu Machinery Manufacturing Co., Ltd. has been engaged in the research and development and production of copper alloy components and self-lubricating bearings for more than ten years, and has rich production experience and technical accumulation. Please feel free to contact us for any product and technical questions.

MXB-JFFB self-lubricating half bearings refer to bearings that cover only half of the circumference of a shaft or axle, providing support and reducing...

See Details

MXB-JDBS bronze-based solid inlaid self-lubricating spherical bearing is a spherical sliding bearing with inner and outer spherical surfaces. It can r...

See Details

The MXB-DUF oil-free composite bearing, also known as the SF-1F bushing, is a three-layer composite structure bearing. It typically consists of a stee...

See Details

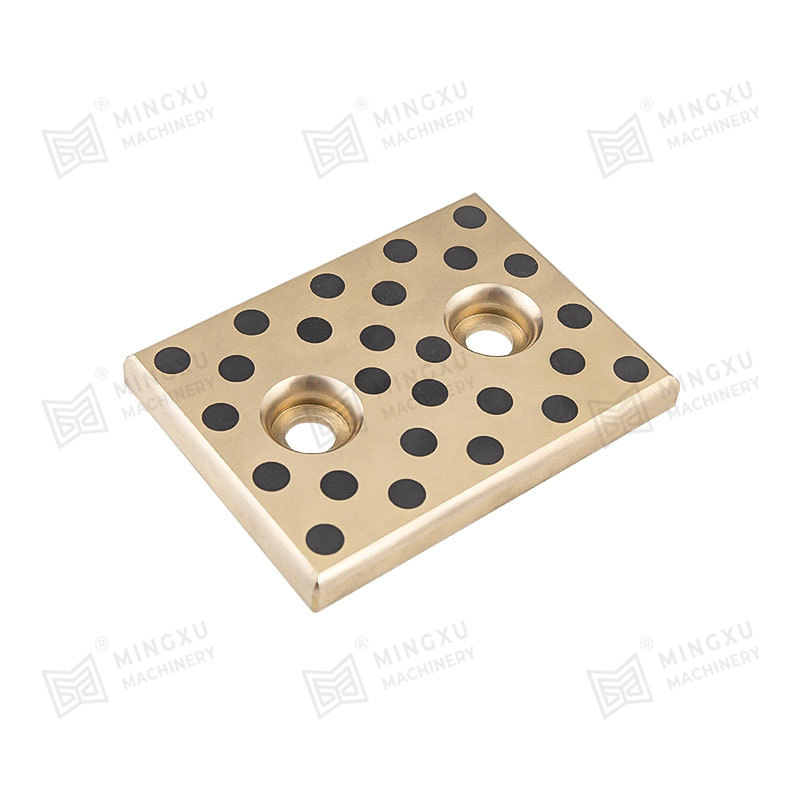

MXB-JSP self-lubricating wear-resistant plate is suitable for injection molding machines, automotive stamping molds, tire molds, factory machinery (ex...

See Details

Circular guides are frequently used in automobile panel molds and large stamping molds. The mold base and unloading plate guides usually use self-lubr...

See Details

MPW VDI3357 Standard Wear Plate is made by inlaying special solid lubricant in the appropriate position. The metal base material supports the load and...

See Details

MJGBF oil-free injection guide bushings are components used in the plastic injection molding process to further improve manufacturing efficiency by en...

See Details

SF-1SS is a highly corrosion-resistant and wear-resistant bearing made of stainless steel as the base material and PTFE sprayed on the surface. This m...

See Details

SF-2X boundary lubricated bearing is based on steel plate, with sintered spherical bronze powder in the middle, modified polyoxymethylene (POM) rolled...

See Details

Boundary lubricated lead-free bearings are improved on the basis of SF-2. Its performance is the same as SF-2, but the surface does not contain lead, ...

See Details

Contact Us